A Miniaturized Laser Synchronous Scanning Triangulation Ranging System

A triangular distance measurement and synchronous scanning technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem that the distance resolution of the horizontal scanning measurement range and the vertical ranging range cannot adapt to the size and distance changes of the measured object, and the structural volume Small and other problems, to achieve the effect of simple structure, small size and fast acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

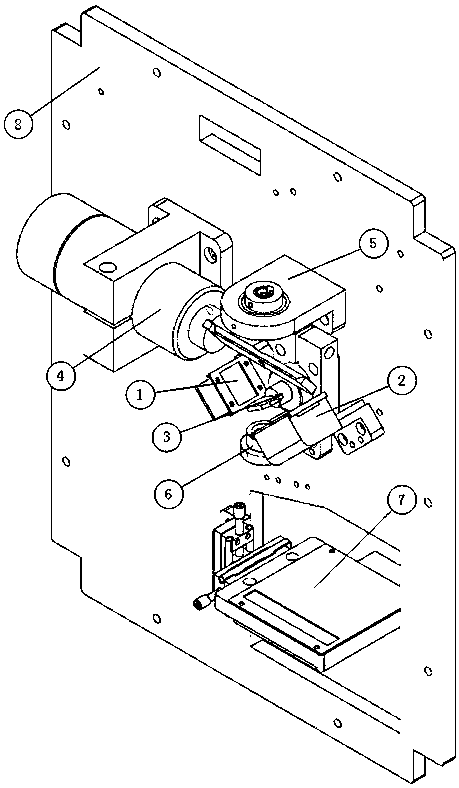

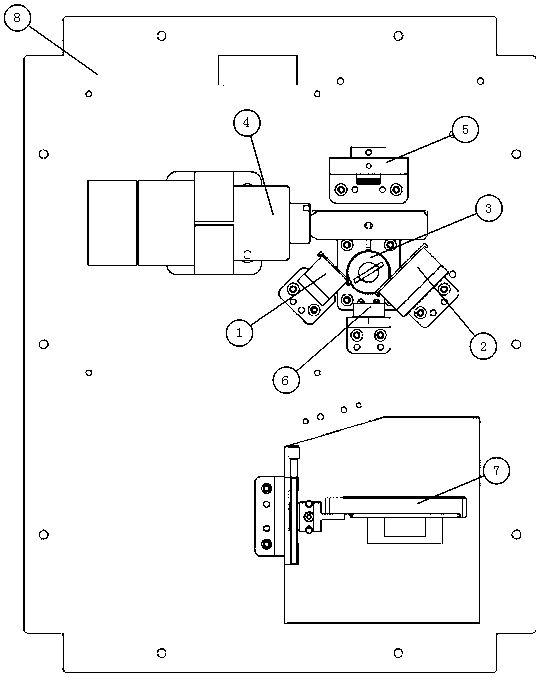

[0044] The miniaturized laser synchronous scanning triangulation ranging system includes M1 mirror part 1, M2 mirror part 2, M3 mirror part 3, M4 mirror part 4, laser part 5, lens part 6, PSD part 7 and base plate 8, and is characterized in that The M3 mirror part 3 is located at the origin of the set space coordinate system, and is vertically fixed on the base plate 8 by hexagon socket bolts; the M1 mirror part 1 and the M2 mirror part 2 are respectively located on the left and right sides of the M3 mirror part 3, and to M3 mirror parts 3 are at the same distance, the angle between M1 mirror part 1 and the horizontal axis is 135°±2°, the angle between M2 mirror part 2 and the horizontal axis is 45°±1°, and they are vertically fixed on the bottom plate 8 by hexagon socket bolts ; The M4 mirror part 4 is vertically fixed on the base plate 8 to ensure that the mirror surface conical hole is located directly above the coordinate origin; the laser part 5, the lens part 6 and the M3...

Embodiment 2

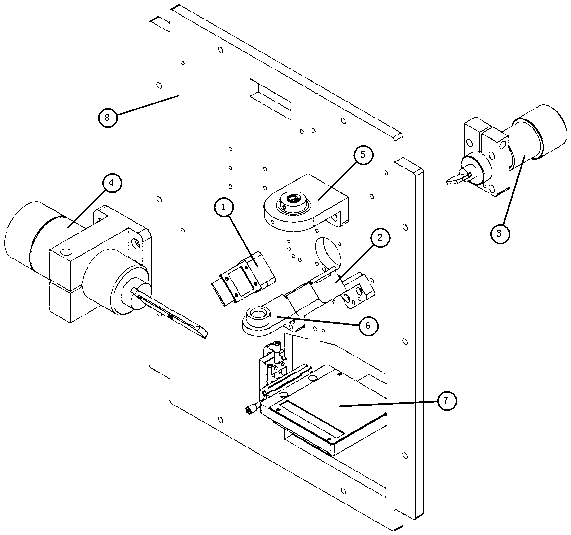

[0046] refer to Figure 4 to Figure 14 , the present embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0047] The M1 mirror component 1 includes an M1 mirror support 9 and an M1 mirror 10, wherein the M1 mirror 10 is a single-sided reflector, and the slot width of the M1 mirror support 9 is slightly larger than the width of the M1 mirror 10 to ensure that the M1 mirror 10 can be placed horizontally on the On the M1 mirror support 9, the M1 mirror 10 is fixed through a cover 10'; the M2 mirror component 2 includes an M2 mirror support 11 and an M2 mirror 12, wherein the M2 mirror 12 is a single-sided mirror, and the M2 mirror support 11 The width of the slot is slightly larger than the width of the M2 mirror 12 to ensure that the M2 mirror 12 can be placed horizontally on the M2 mirror support 11, and the M2 mirror 12 is fixed through a cover piece 12'; the M3 mirror part 3 includes the M3 mirror 13, the M3 mirror vibration Mirror mot...

Embodiment 3

[0056] see Figure 15 , the miniaturized laser synchronous scanning triangulation ranging system of the present invention is as follows:

[0057] 1. Turn on the laser and PSD, adjust the appropriate laser power, the laser energy should not be too weak. Initialize the ranging system, open the galvanometer control software to reset, and make the M3 and M4 mirrors return to the initial angle position;

[0058] 2. The host computer issues instructions to control the swing angle of the vibrating mirror motor. The M3 and M4 mirrors perform reciprocating swing motion around the axis at the same time. The laser scans the raster track on the surface of the measured object, and the diffuse reflection light is focused on the PSD surface by the lens;

[0059] 3. PSD detects the position of the light spot, converts the position information into a voltage value output, and the multi-channel acquisition system simultaneously collects and transmits the voltage value output by the angle sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com