Planetary rolling mill key parameter online monitoring data acquisition analysis system

A technology of key parameters and monitoring data, which is applied in the field of rolling equipment production, can solve problems that restrict corporate decision-making and risk control, product quality is difficult to control and trace, and production costs fluctuate greatly, achieving an effect that is easy to grasp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiment:

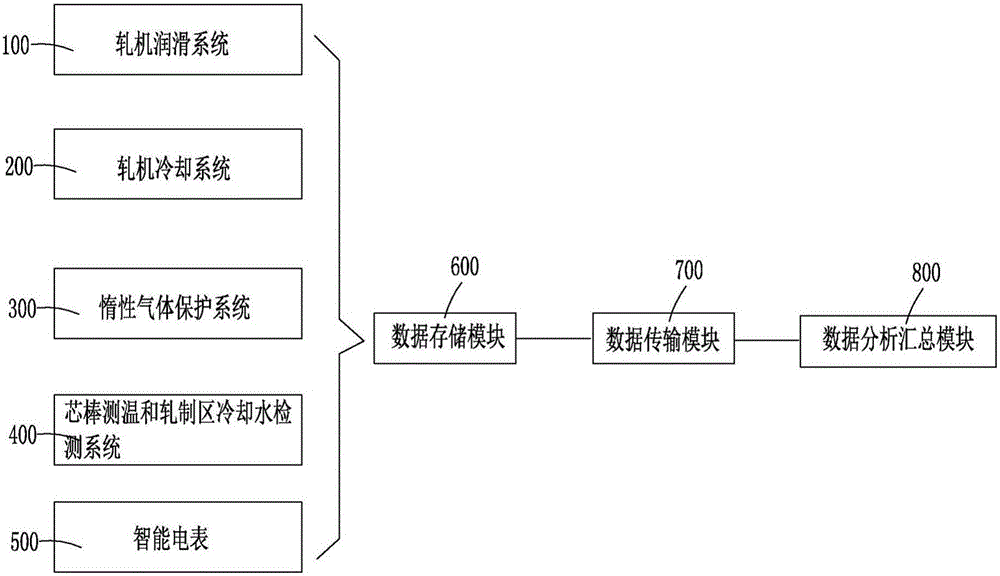

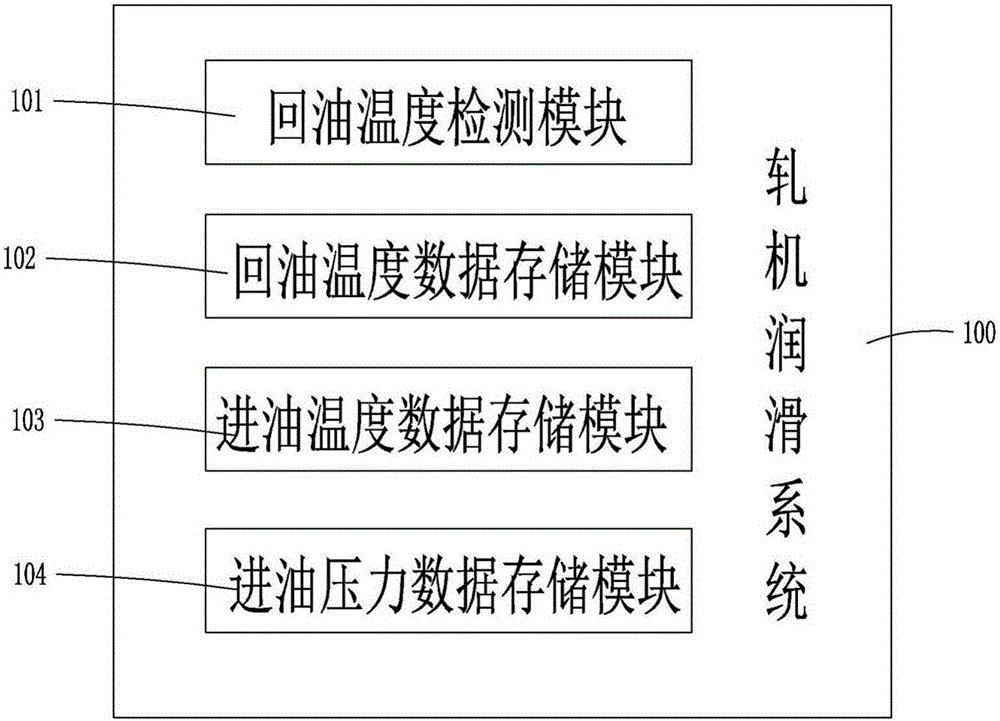

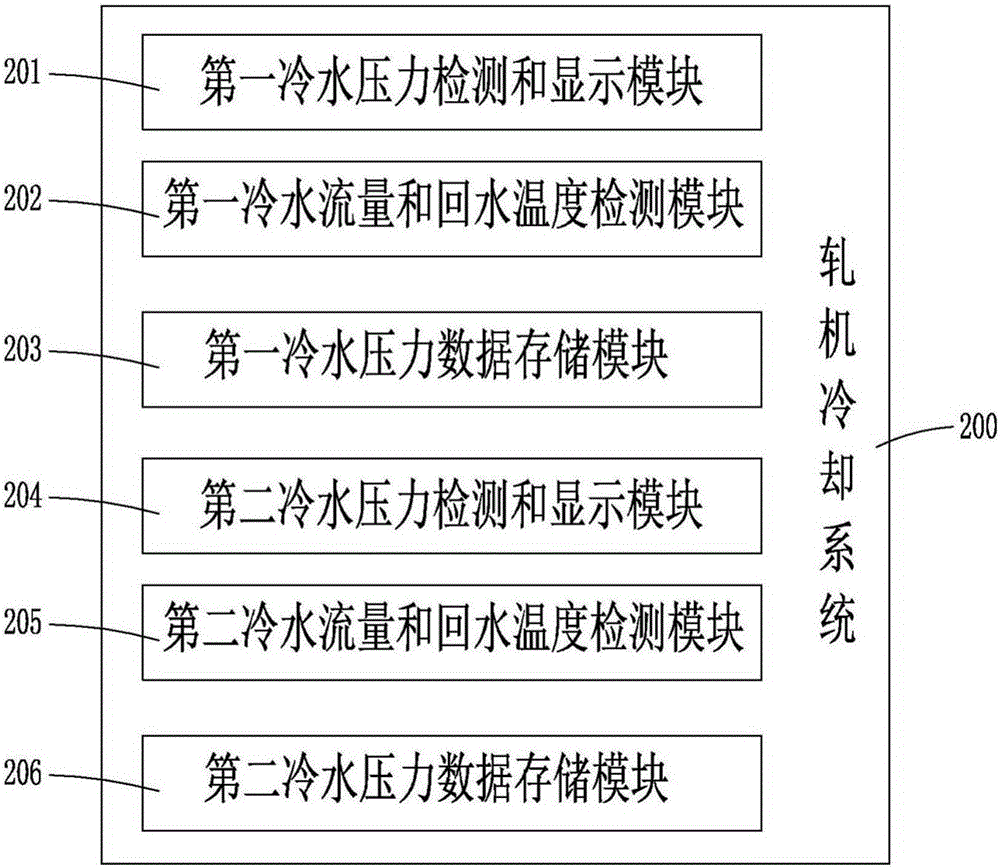

[0017] Please refer to the attached Figures 1 to 5 As shown, a planetary rolling mill key parameter online monitoring data acquisition and analysis system described in this embodiment includes a rolling mill lubrication system 100, a rolling mill cooling system 200, an inert gas protection system 300, mandrel temperature measurement and rolling area cooling water Detection system 400, smart meter 500 (smart meter can obtain the power consumption parameters in the production process in real time, so in the actual production process, technicians can make a reasonable arranging production), data storage module 600, data transmission module 700 and data analysis and summary module 800, wherein the rolling mill lubrication system 100 includes an oil return temperature detection module, an oil return temperature data storage module 102, an oil inlet temperature detection and data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com