Teaching model of automobile automatic transmission

An automatic transmission, teaching model technology, applied in teaching models, instruments, educational appliances, etc., can solve the problems of long time, difficult disassembly and assembly, high technical requirements, complex structure, etc., and achieves convenient power input, convenient and intuitive demonstration, and structural connection. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with drawings and embodiments.

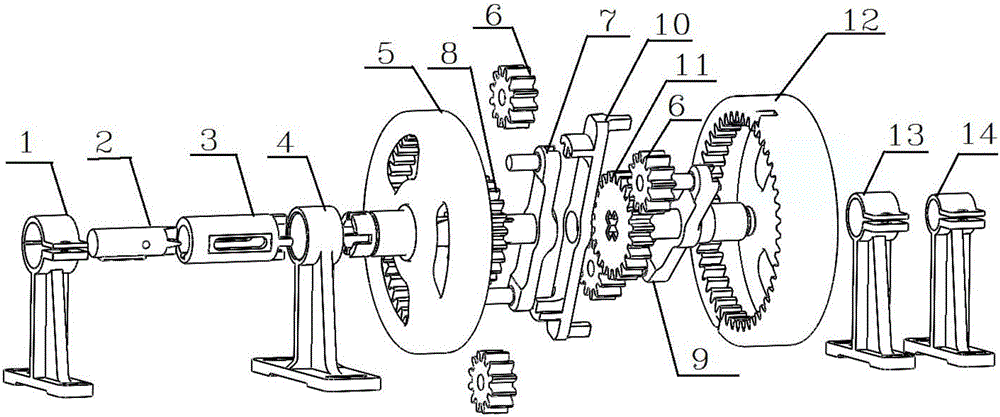

[0039] Such as Figure 1-Figure 15 The automobile automatic transmission teaching model shown includes large support 1, inner clutch 2, outer clutch 3, left support 4, left ring gear 5, four planetary gears 6, left planet carrier 7, left sun gear 8, right Planet carrier 9, connecting frame 10, right sun gear 11, right ring gear 12, right planet carrier seat 13 and right sun wheel seat 14, wherein,

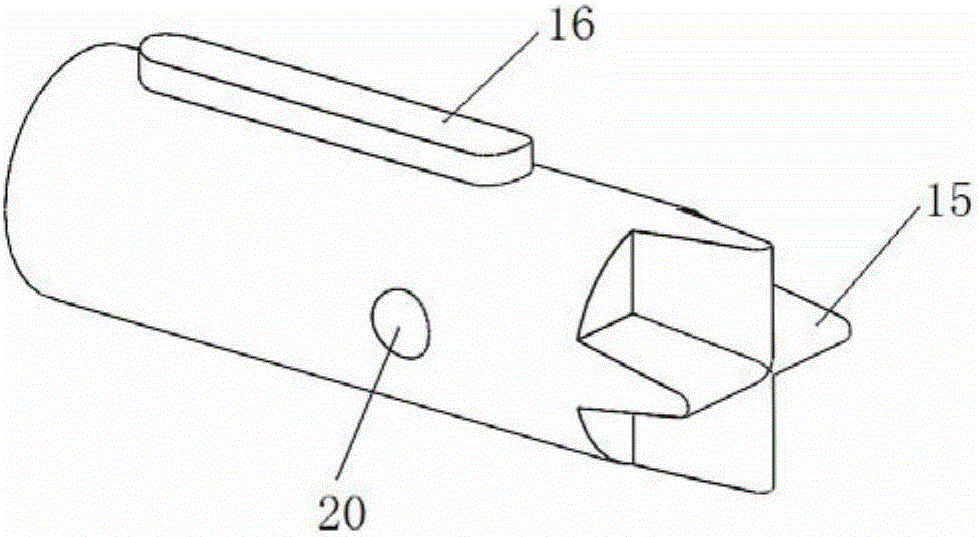

[0040] The right end of the inner clutch 2 is provided with a cross protrusion 15, and the peripheral surface of the inner clutch 2 is provided with a linear guide protrusion 16;

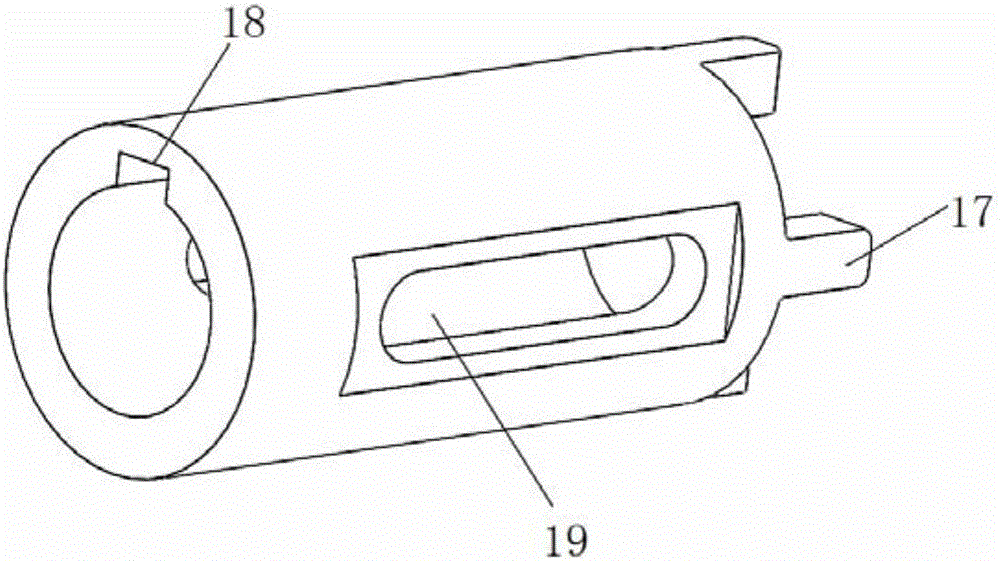

[0041] The outer clutch 3 is a hollow sleeve structure, and the right end is provided with four inserting posts 17 separated by 90°, and the inner wall is provided with a linear guide groove 18;

[0042] The left end of the left ring gear 5 is provided with a left sleeve 21, and the left end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com