Production method of embossing device for sealing strips

A sealing strip and embossing technology, which is applied in the field of preparation of embossing devices, can solve the problems of machine adjustment waste and other problems, and achieve the effects of reducing equipment cost, reducing occupied space, and simple structural connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

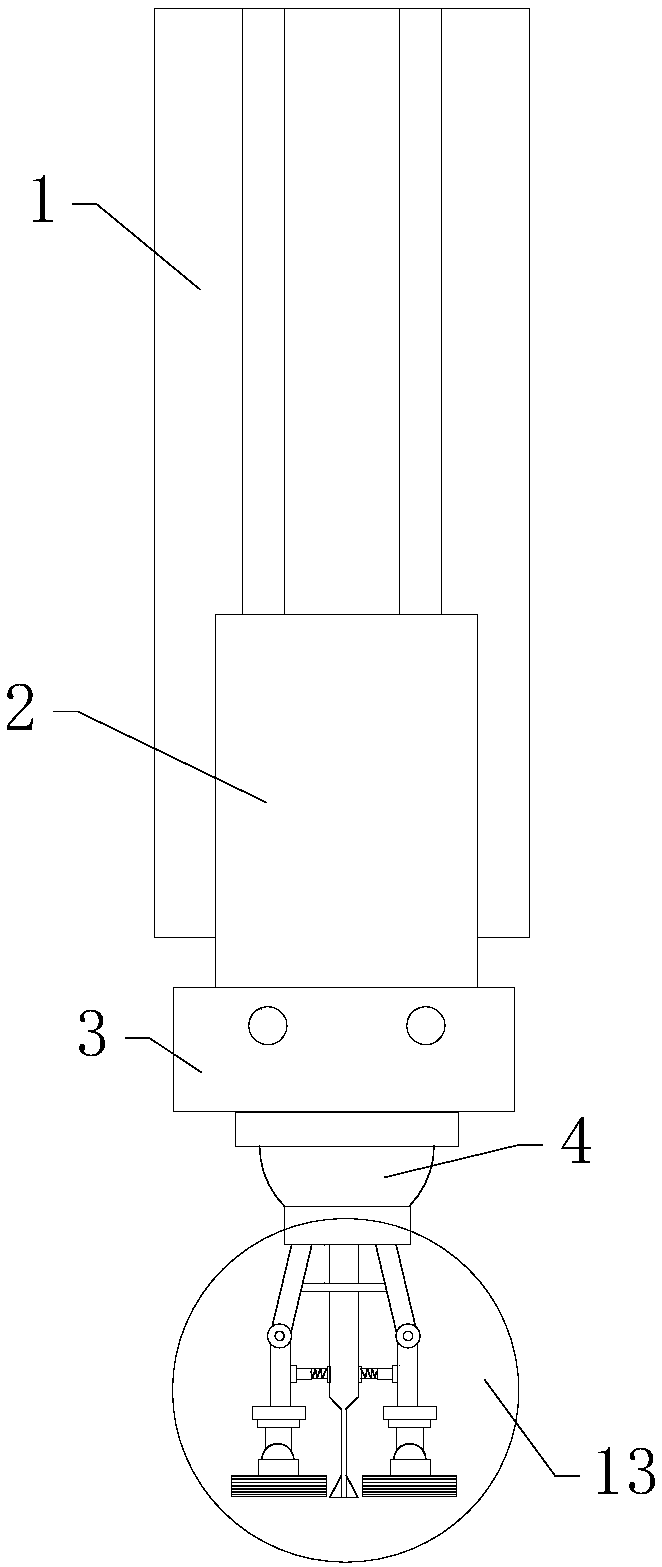

[0025] Such as figure 1 As shown, a preparation method 13 of an embossing device for a sealing strip includes a support plate 1, a slider 2, a large steering shaft 4 and an embossing device 13, the support plate 1 is provided with a slider 2, and the The lower end of the slider 2 is provided with a large steering shaft 4, and an embossing device 13 is provided below the large steering shaft 4;

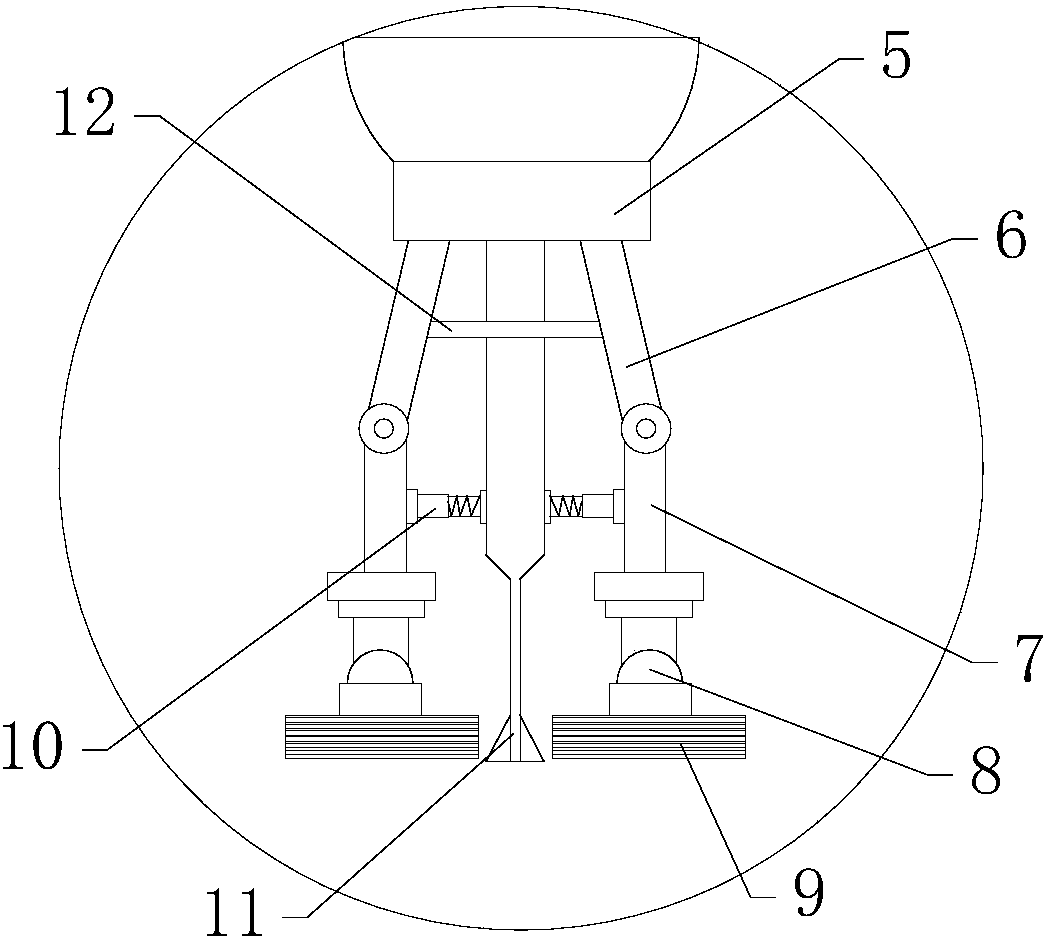

[0026] The embossing device 13 includes a connecting block 5, a first connecting rod 6, a second connecting rod 7, a slotted plate 11 and an embossing roller 9, and the connecting block 5 is arranged below the large steering shaft 4, and the The first connecting rod 6 is arranged below the connecting block 5, the tail end of the first connecting rod 6 is provided with the second connecting rod 7, and the tail end of the second connecting rod 7 is provided with an embossing roller 9, so A slotted plate 11 is also provided in the middle of the connecting block 5 .

[0027] The first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com