A self-adaptively adjustable yag solid-state laser and its application method

An adaptive adjustment and solid-state laser technology, which is applied in the field of YAG lasers, can solve the problems of adjustment lag, unstable quality, time-consuming and labor-intensive problems, and achieve the effects of reducing experience requirements, improving optical path reliability, and avoiding mechanical deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiment of adaptively adjusted YAG solid-state laser

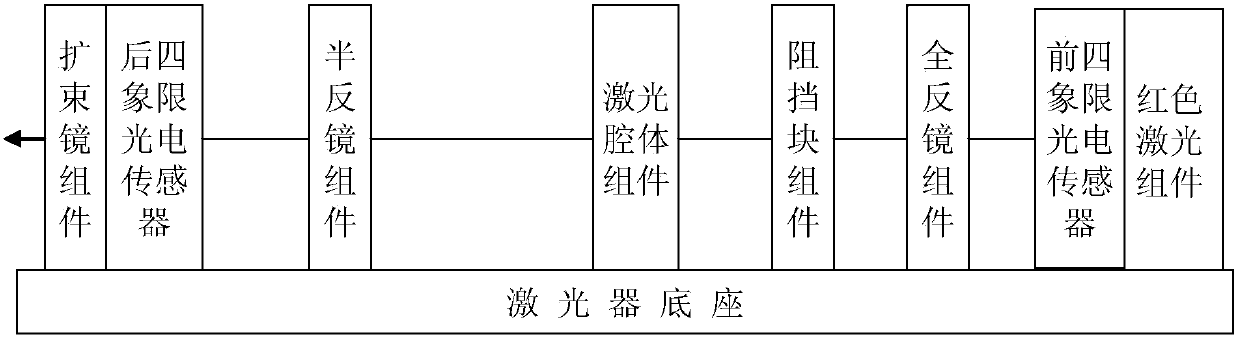

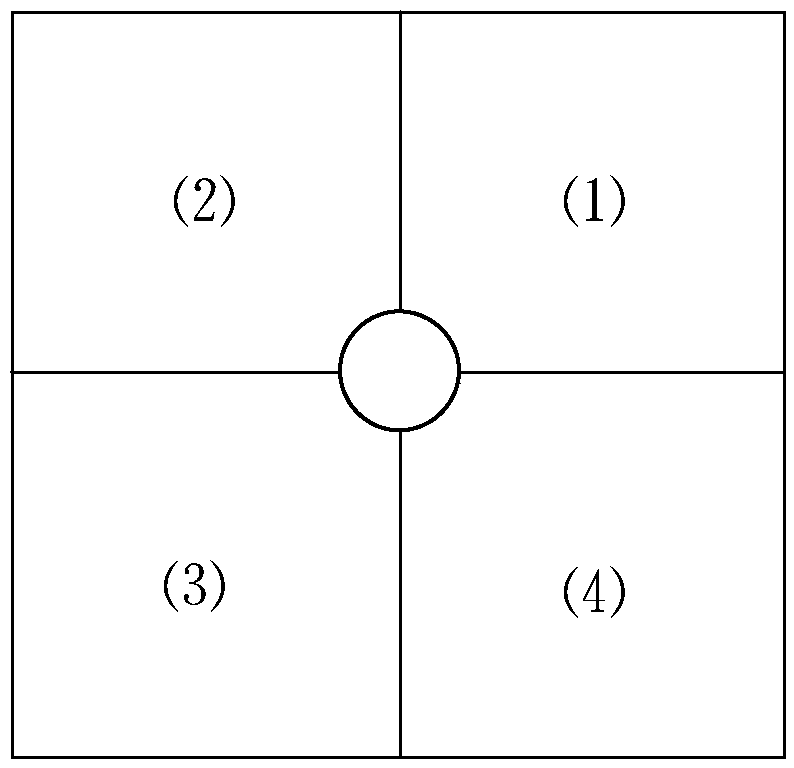

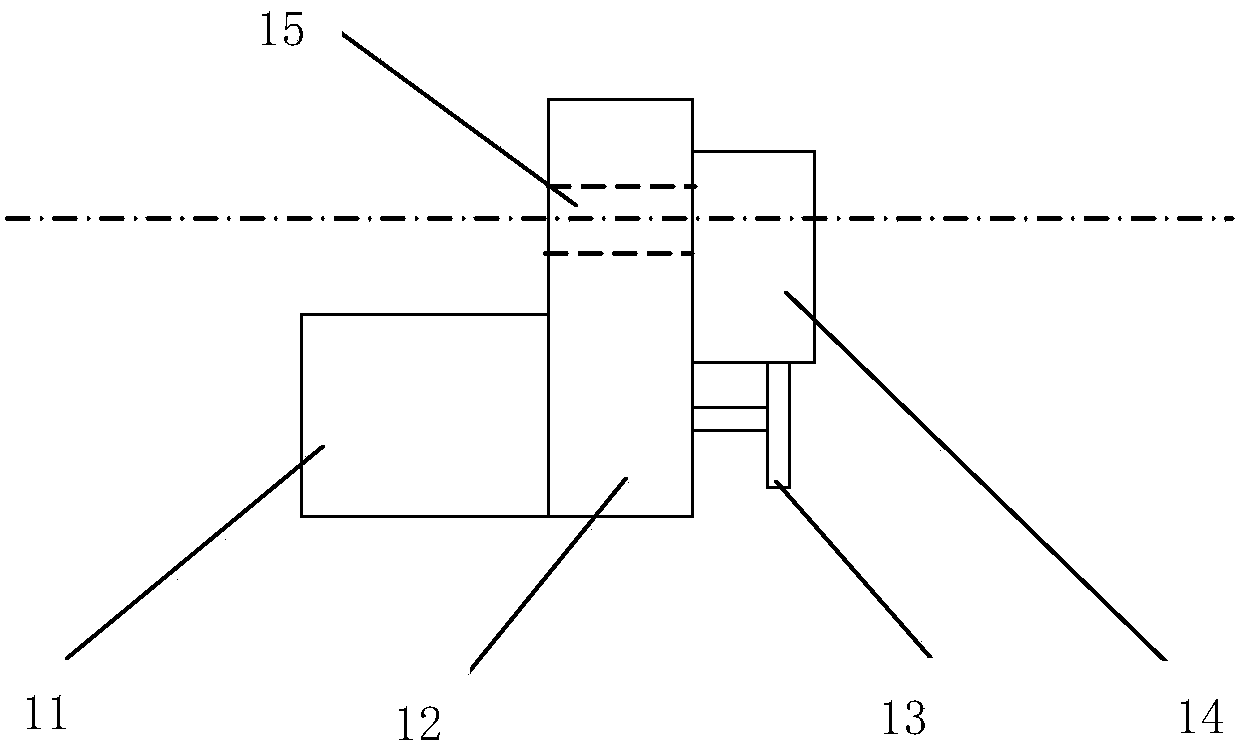

[0053] The structure of this adaptively adjusted YAG solid-state laser embodiment is as follows figure 1 As shown, it includes a red laser component, a full mirror component, a laser cavity component, a half mirror component and a beam expander component installed on the laser base in sequence from back to front, and the centers of the above components are all on a straight line optical axis , the laser light generated by the laser cavity assembly is sent out from the front end of the laser through the full reflection mirror, half reflection mirror and beam expander, which is the laser cutting head. The red laser component installed at the end of the laser is a red laser device installed on the H fine-tuning frame; the full-mirror component is a full-reflective mirror mounted on the Q fine-tuning frame, and the half-mirror component is a half-mirror mounted on the B fine-tuning frame mirror. The red positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com