AGV battery charging device

A charging device and storage battery technology, applied in the direction of battery circuit devices, circuit devices, collectors, etc., can solve the problems of reducing charging flexibility and fluency, affecting the use efficiency of AGV, etc., so as to improve charging flexibility and enhance power receiving reliability The effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Example: Combining Graphs 1 and diagram 5 The present invention provides such AGV The details of the battery charging device are as follows:

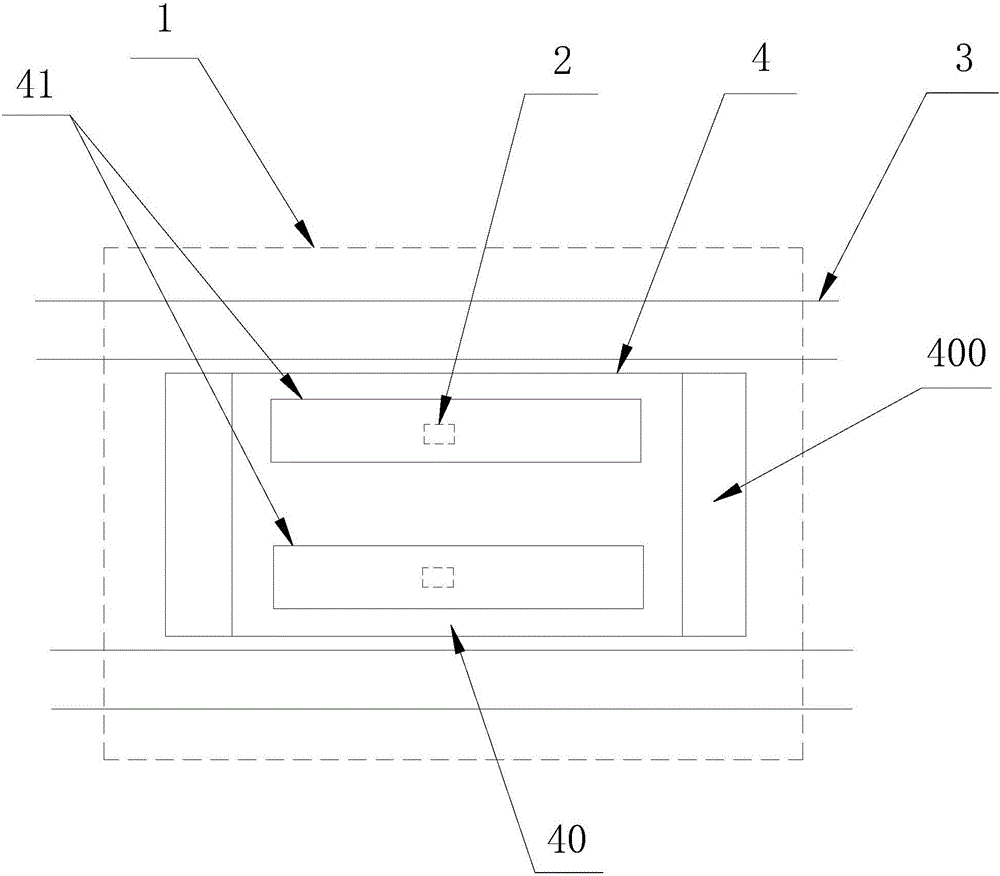

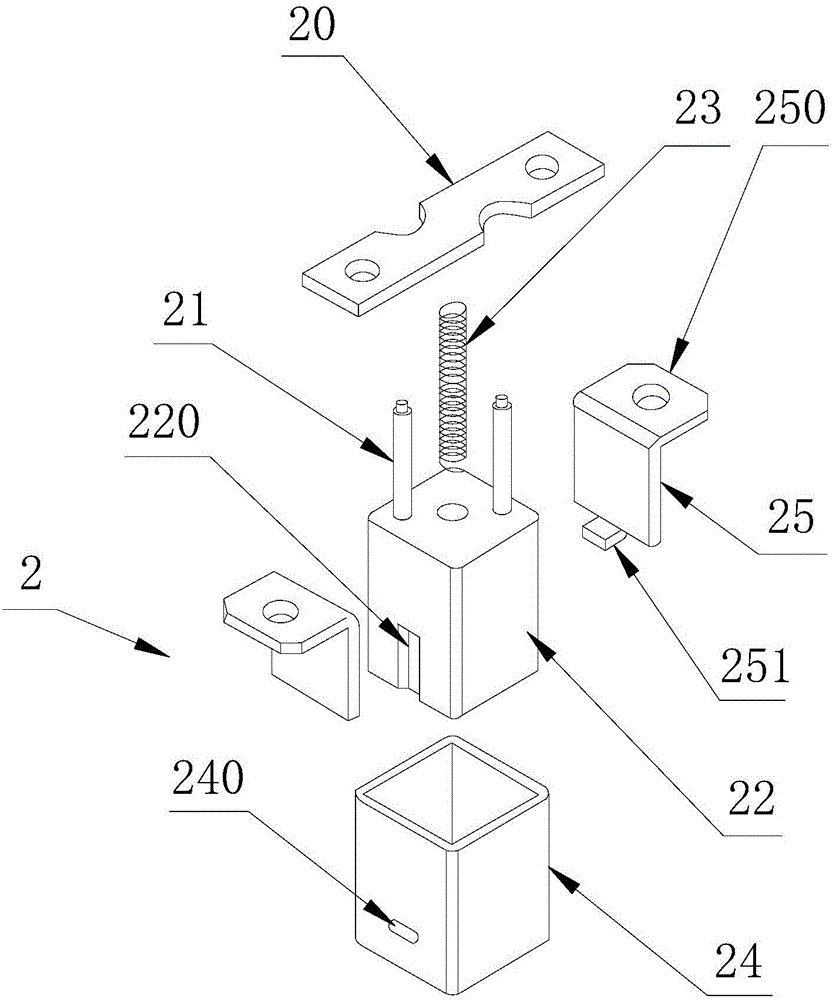

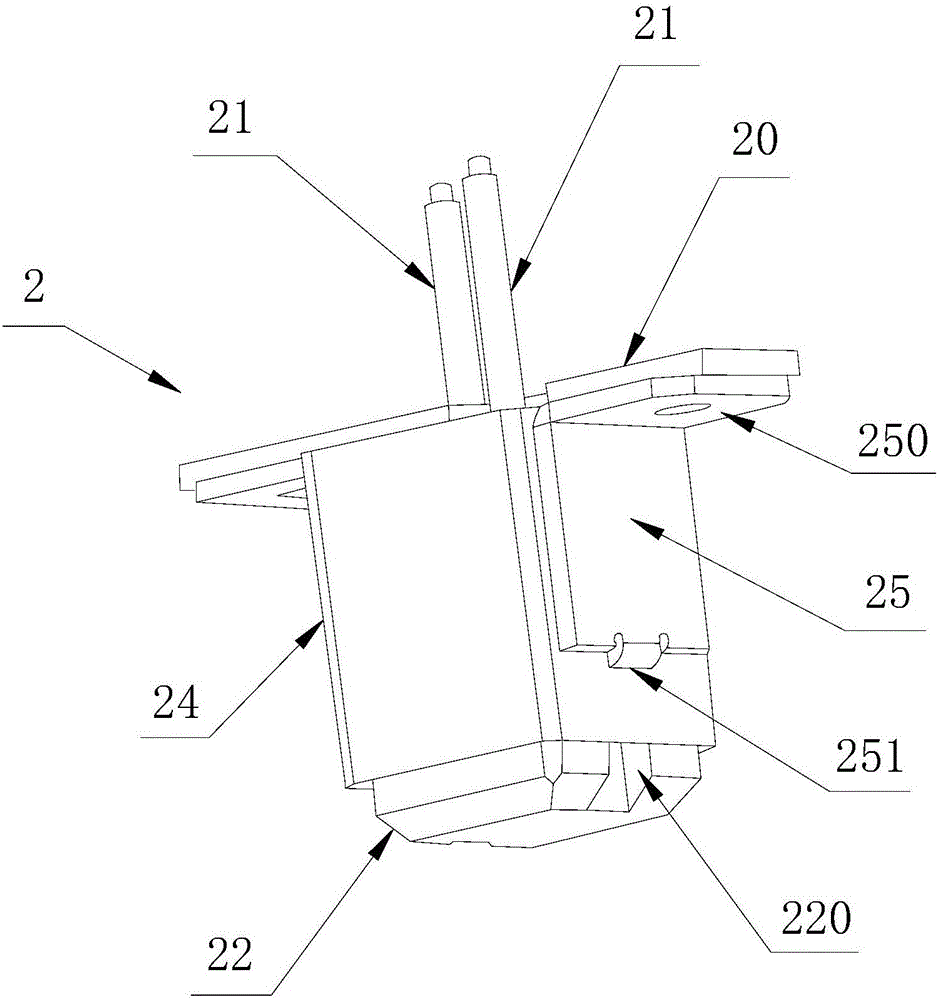

[0032] The charging device in this embodiment consists of AGV 1 (picture 1 middle dotted frame) and electrically connected to the vehicle battery (not shown in the figure) AGV The charging station is composed of a charging socket electrically connected to the charging station power supply (DC power supply, not shown in the figure) and related control circuits. The charging male head is two brush blocks respectively connected to the positive and negative poles of the vehicle battery 2 , and the charging female head is set at AGV 1 running guide rail 3 brush plate on middle ground 4 , see figure 1 shown.

[0033] Combined graph 1 and diagram 4 As shown, the brush plate described in this embodiment 4 insulating substrate 40 and fixed on an insulating substrate 40 above and res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com