Patents

Literature

41results about How to "Guaranteed contact force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

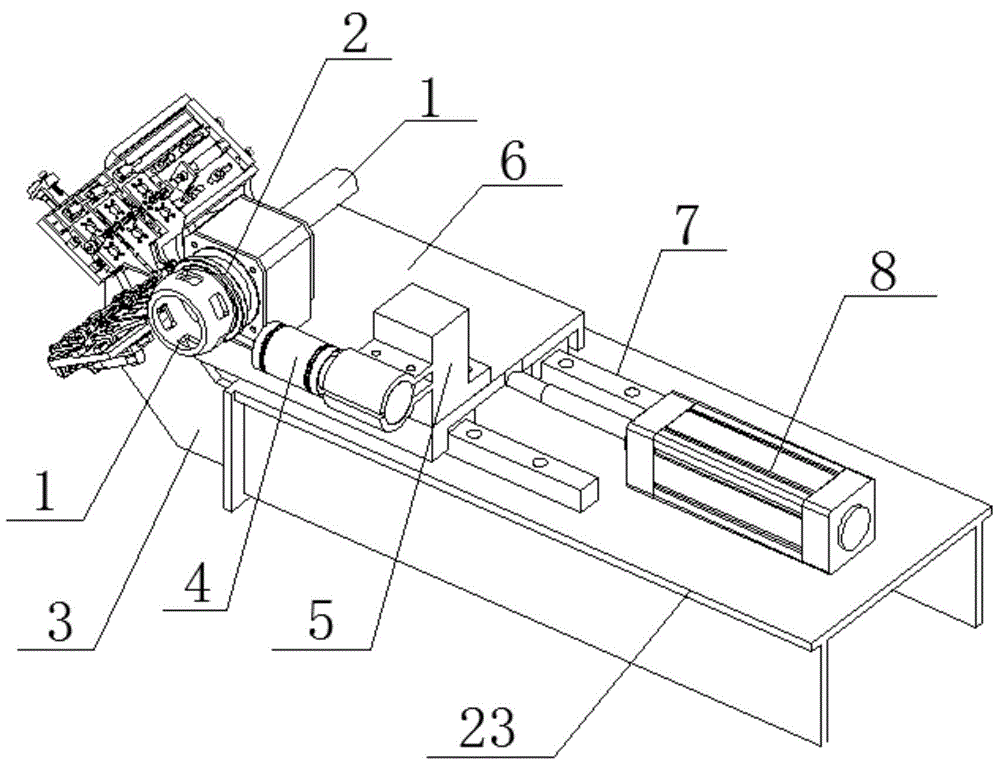

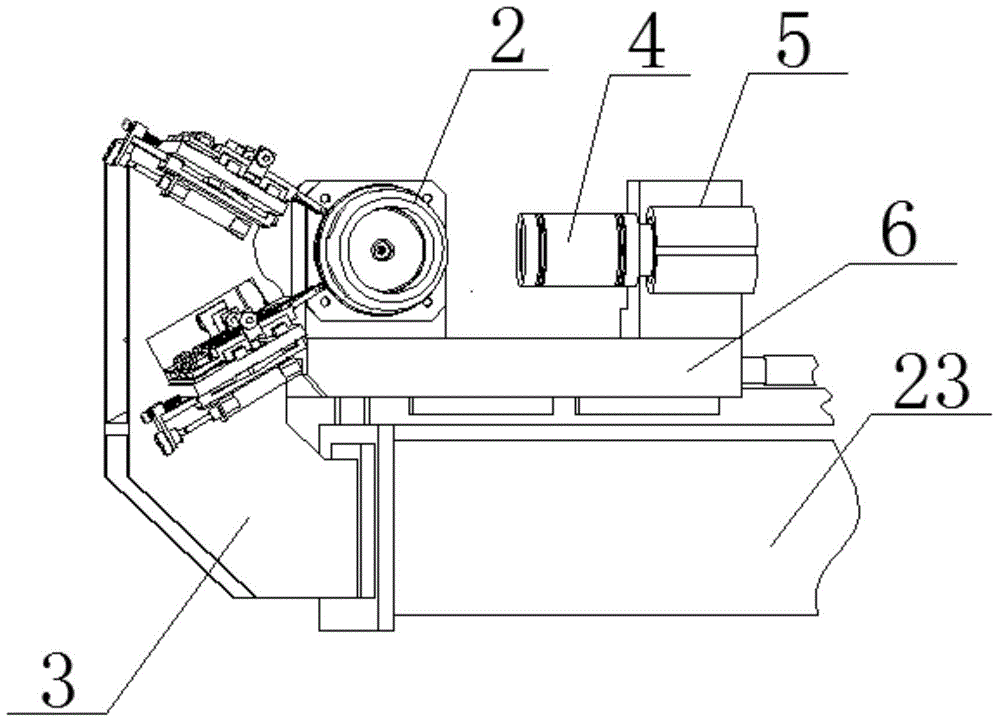

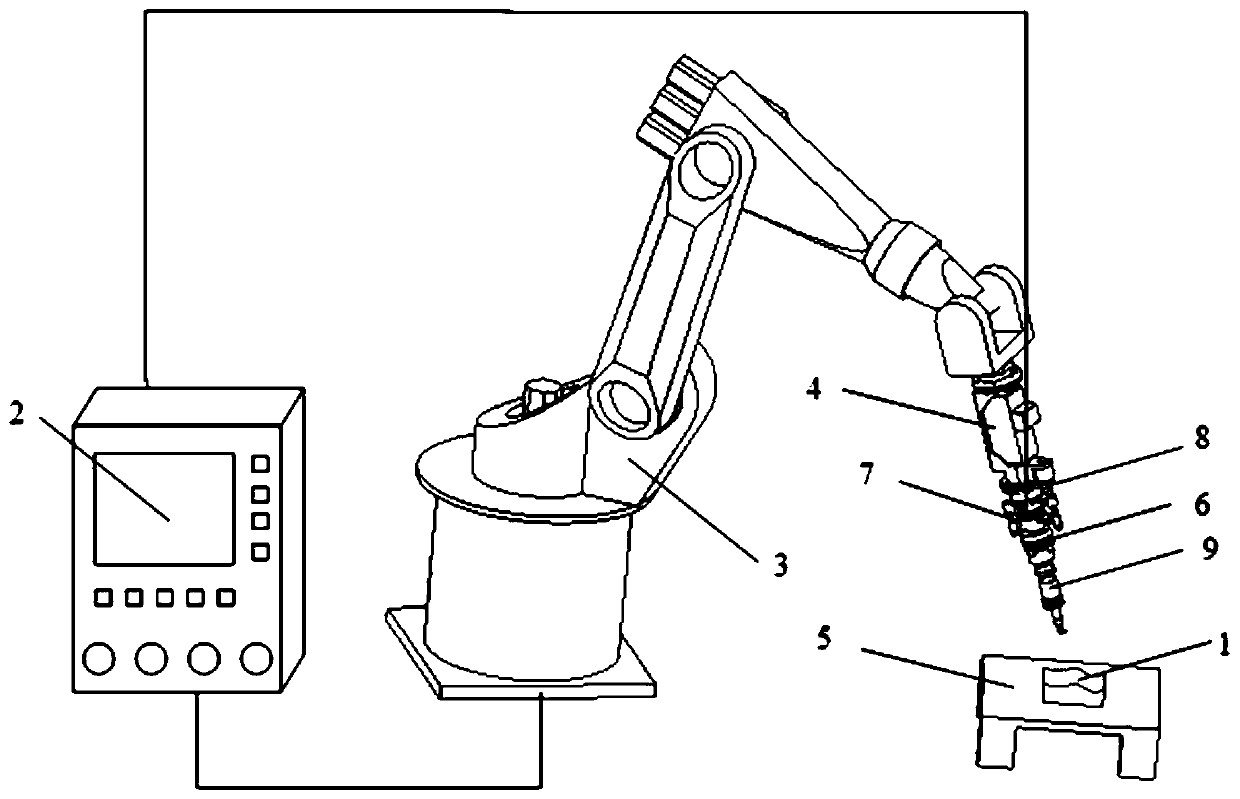

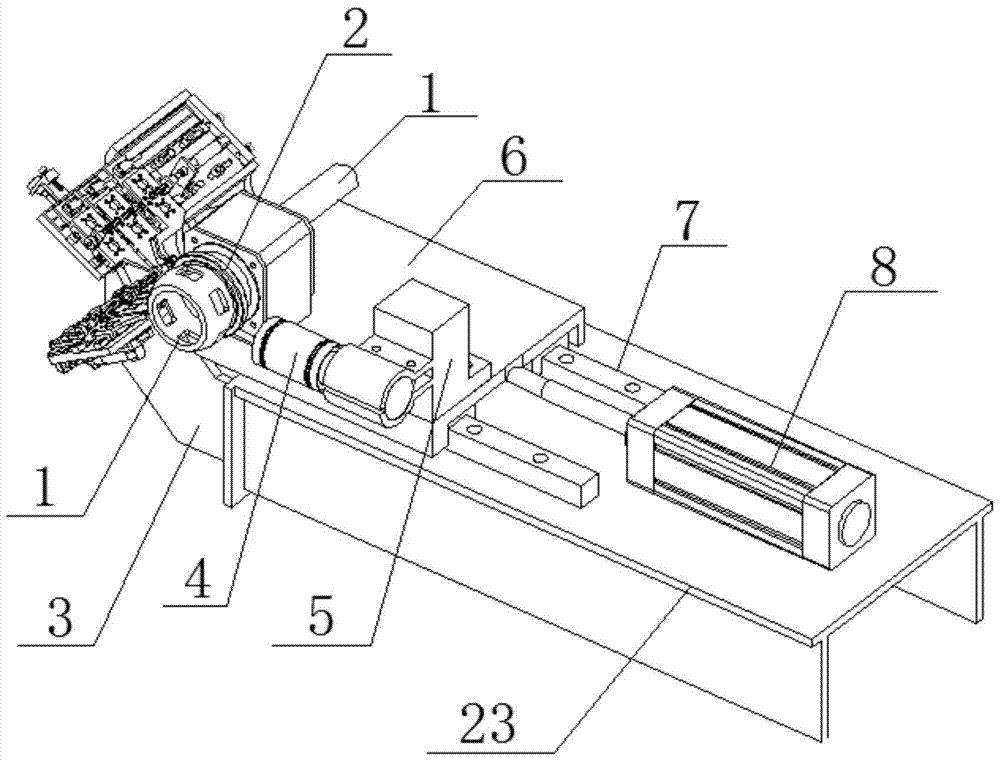

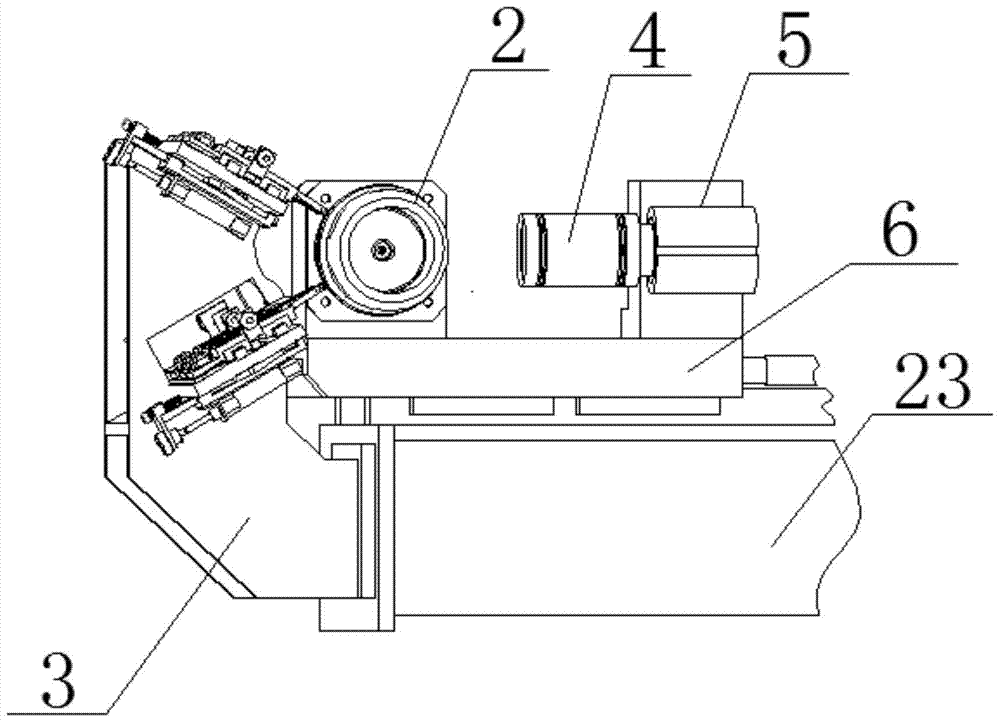

Adaptive polishing robot mechanism

InactiveCN102699790AEasy access or separationGood flexibility and adaptabilityGrinding machinesManipulatorDrive motorManipulator

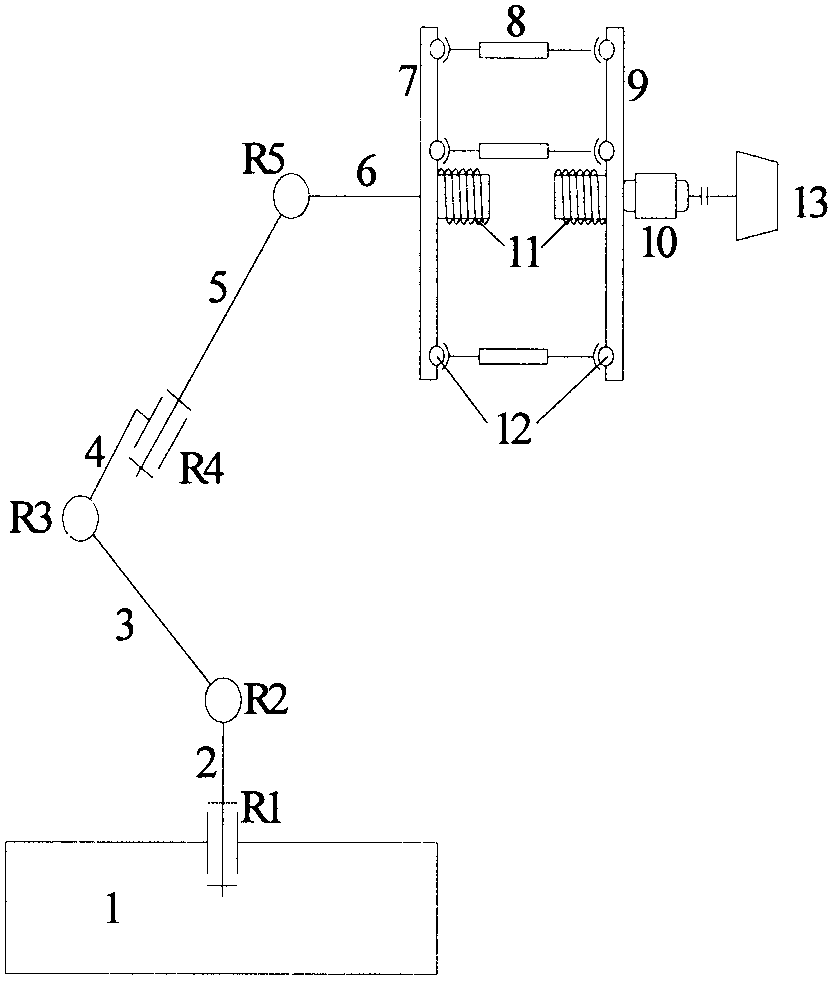

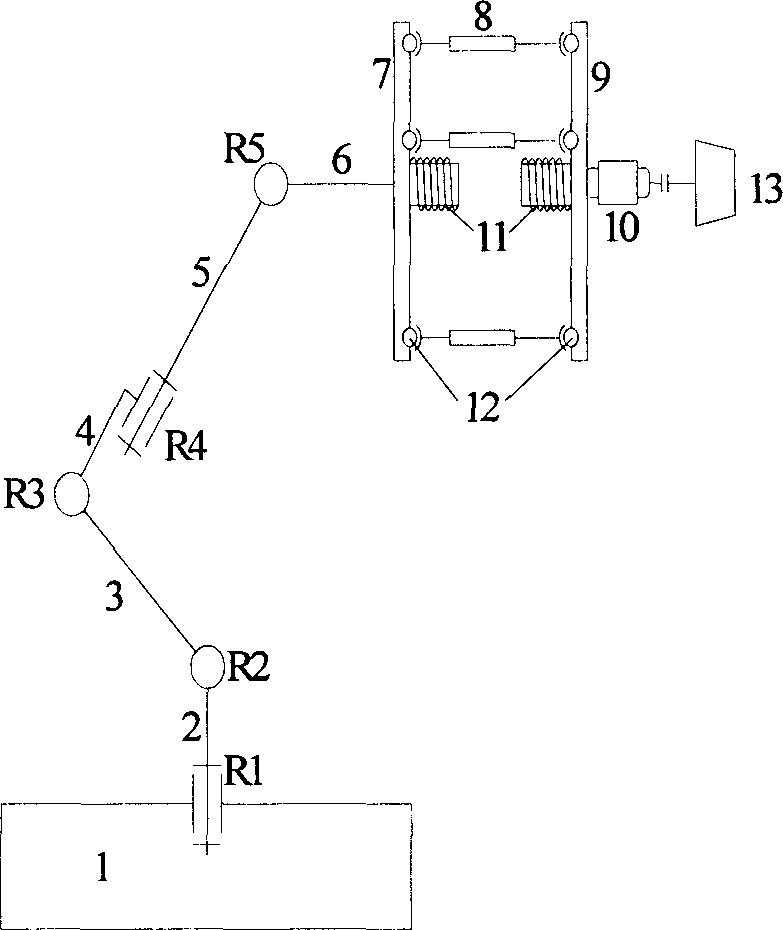

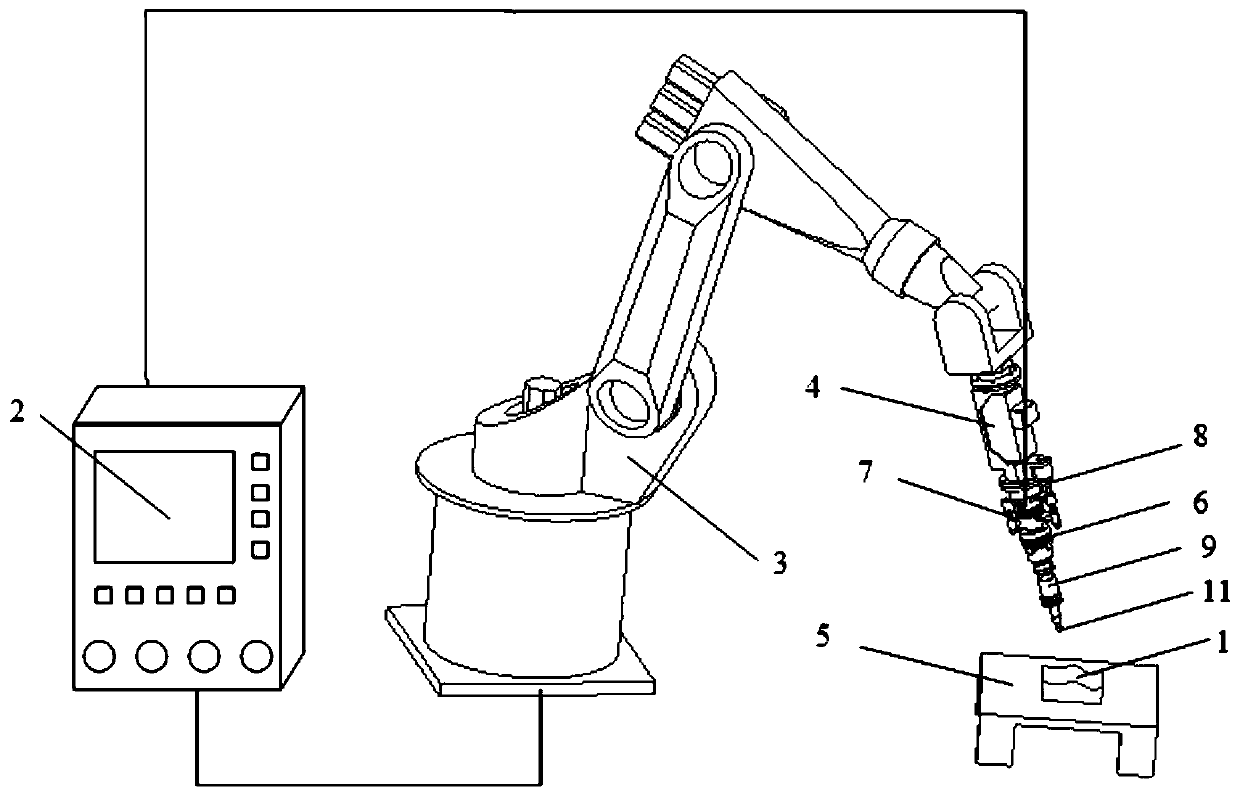

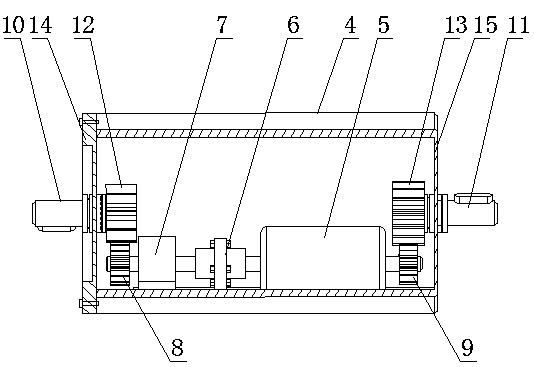

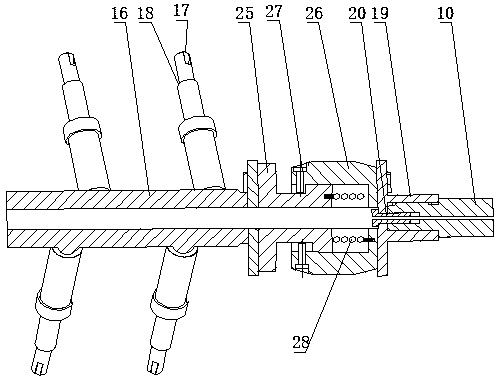

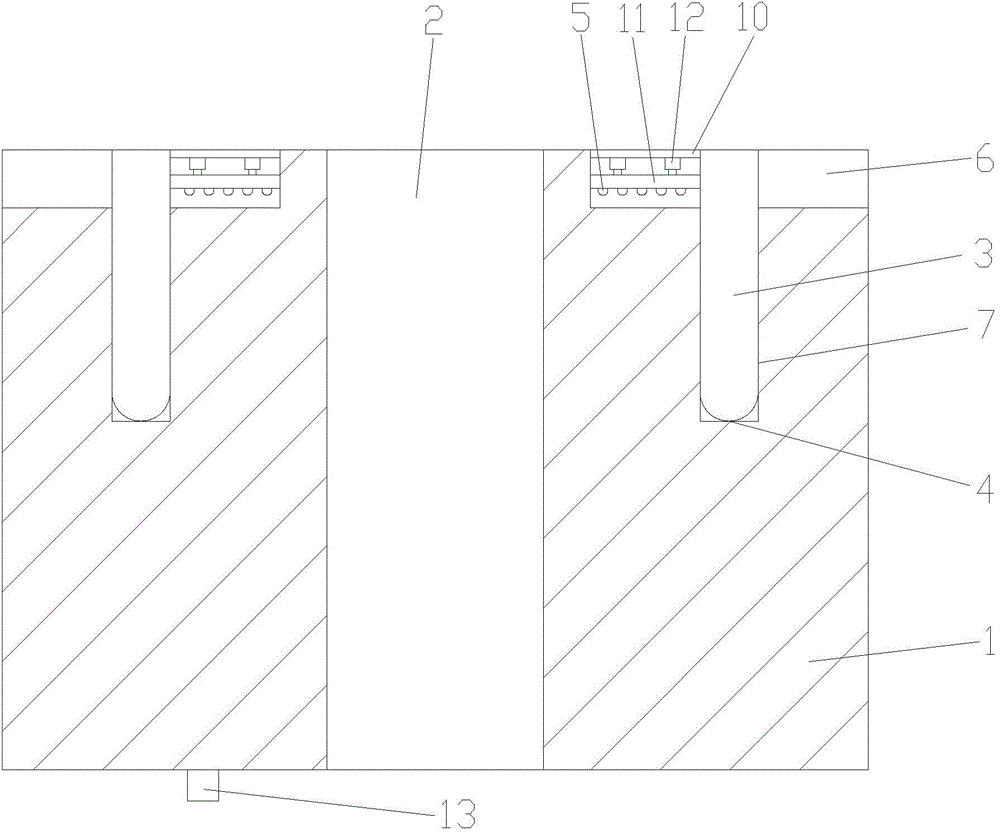

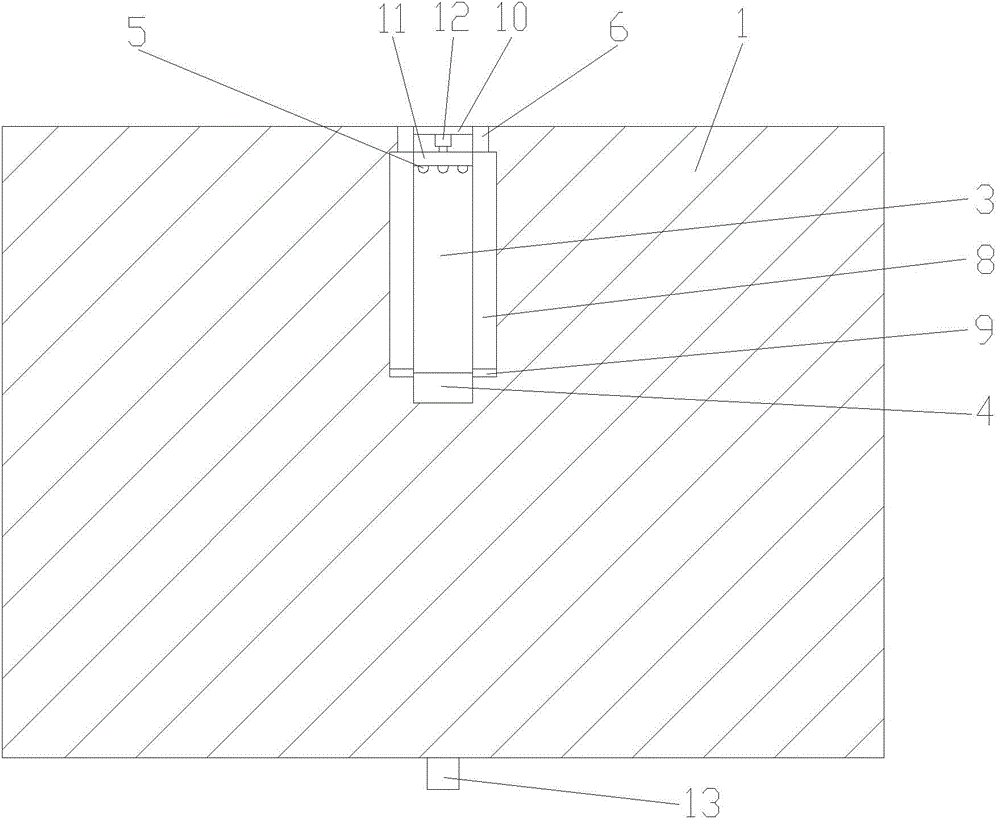

The invention relates to an adaptive polishing robot mechanism. The mechanism comprises a serially connected mechanical hand and a telescopic parallelly connected polishing head, wherein the serially connected mechanical hand is formed by serially connecting a base (1), a first rod (2), a second rod (3), a third rod (4), a fourth rod (5) and a tail end member (6) in sequence through a first revolute pair (R1), a second revolute pair (R2), a third revolute pair (R3), a fourth revolute pair (R4) and a fifth revolute pair (R5); the telescopic parallelly connected polishing head comprises a fixed platform (7), a movable platform (9), a polishing head (13) and three gas springs (8); the fixed platform (7) is fixed on the tail end member (6); electromagnets (11) with opposite magnetic poles are fixed in the centers of the fixed platform (7) and the movable platform (9); the two ends of each of the three gas springs (8) are connected with the fixed platform (7) and the movable platform (9) through ball pairs (12); the three gas springs (8) are uniformly distributed between the fixed platform (7) and the movable platform (9); and the polishing head (13) is connected with a driving motor (10) fixed on the movable platform (9). The polishing robot mechanism has the advantages of simple structure, high working efficiency and the like, is easy to control and can be used for polishing a large-area irregular curved surface.

Owner:CHANGZHOU UNIV +1

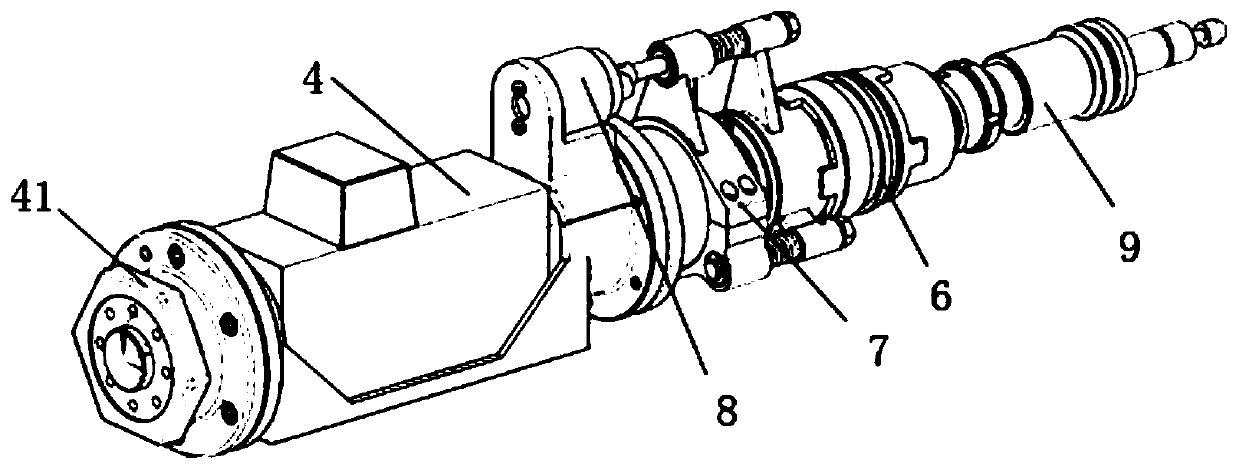

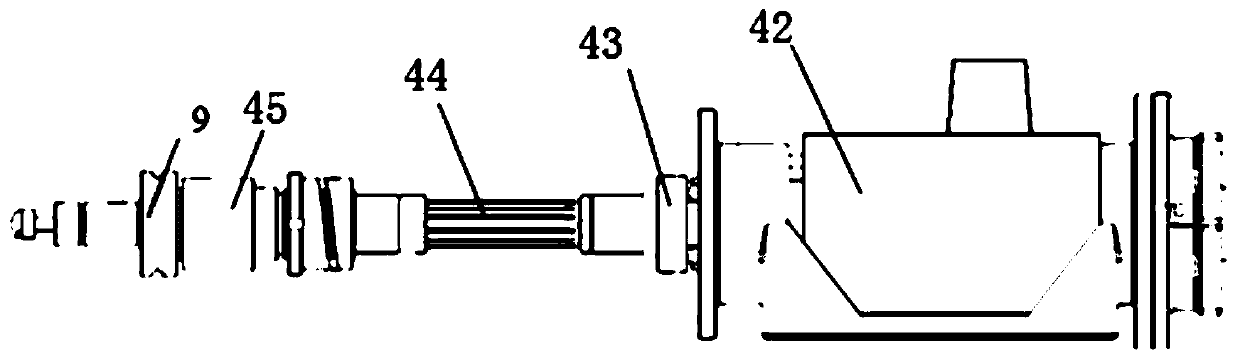

Non-structure freeform curved surface grinding device

ActiveCN110695809AQuick responseImprove sanding efficiency and surface finishGrinding wheel securing apparatusGrinding feed controlPhysicsSurface grinding

The invention discloses a non-structure freeform curved surface grinding device. Due to the arrangement of a pressing floating mechanism, a six-dimensional force sensor, an active control mechanism and a six-degree-of-freedom manipulator, stress conditions of a plurality of dimensions of a grinding head can be measured in real time through the six-dimensional force sensor. Different active and passive compliance control modes can be adopted by a controller according to the change of the stress conditions in the grinding process, the speed of responding to polishing force changes in the grinding process is improved, the contact force between a grinding head and the ground surface in the grinding process can be kept within a certain reasonable range all the time, and meanwhile, the directionof the grinding force is always in the vertical direction of the ground curved surface. By controlling the running track of the six-degree-of-freedom manipulator, the grinding track of the grinding head is adjusted, the non-structure freeform curved surface of a part to be machined is ground, grinding force control is carried out, the grinding efficiency and the surface finish are effectively improved, the labor intensity is reduced, and meanwhile, the part grinding quality is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

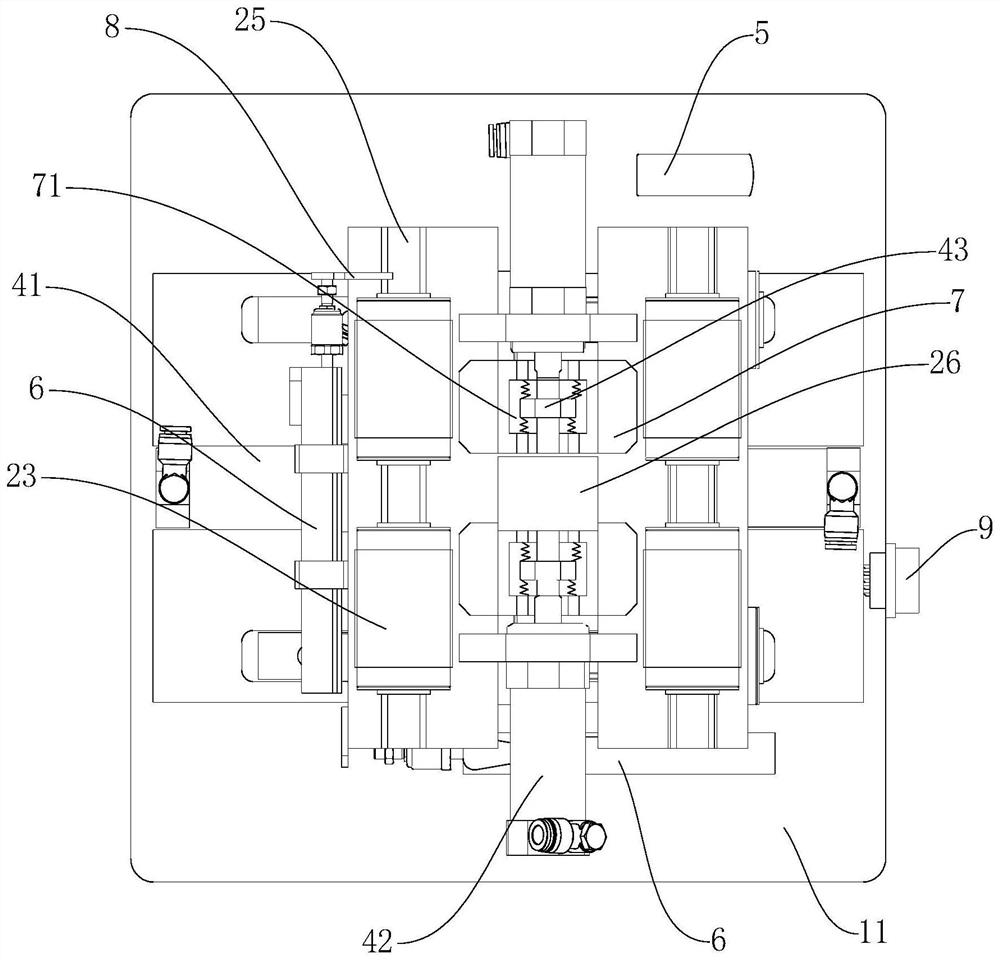

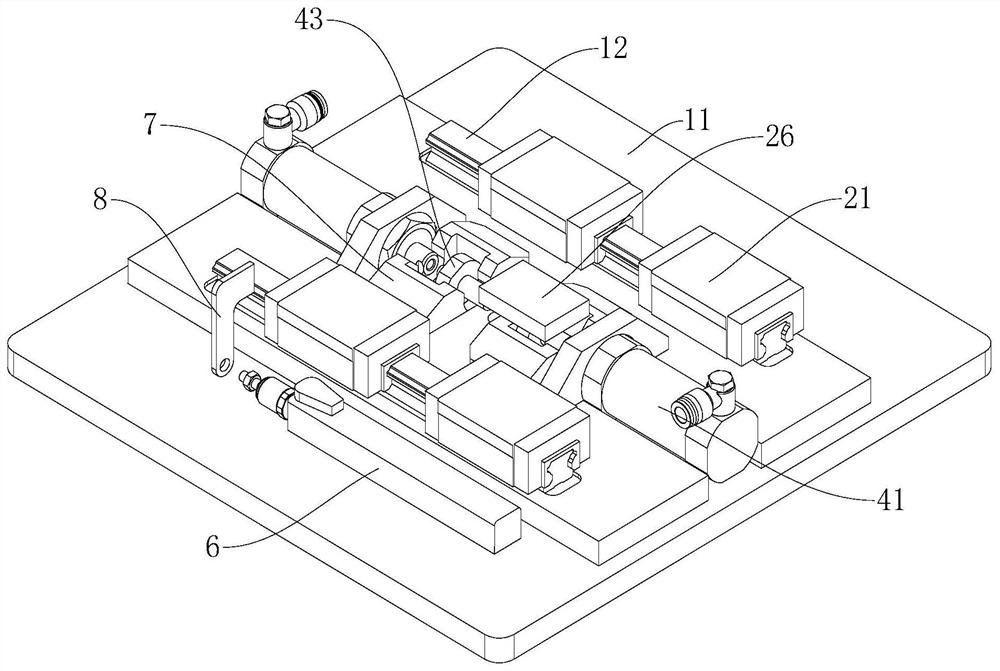

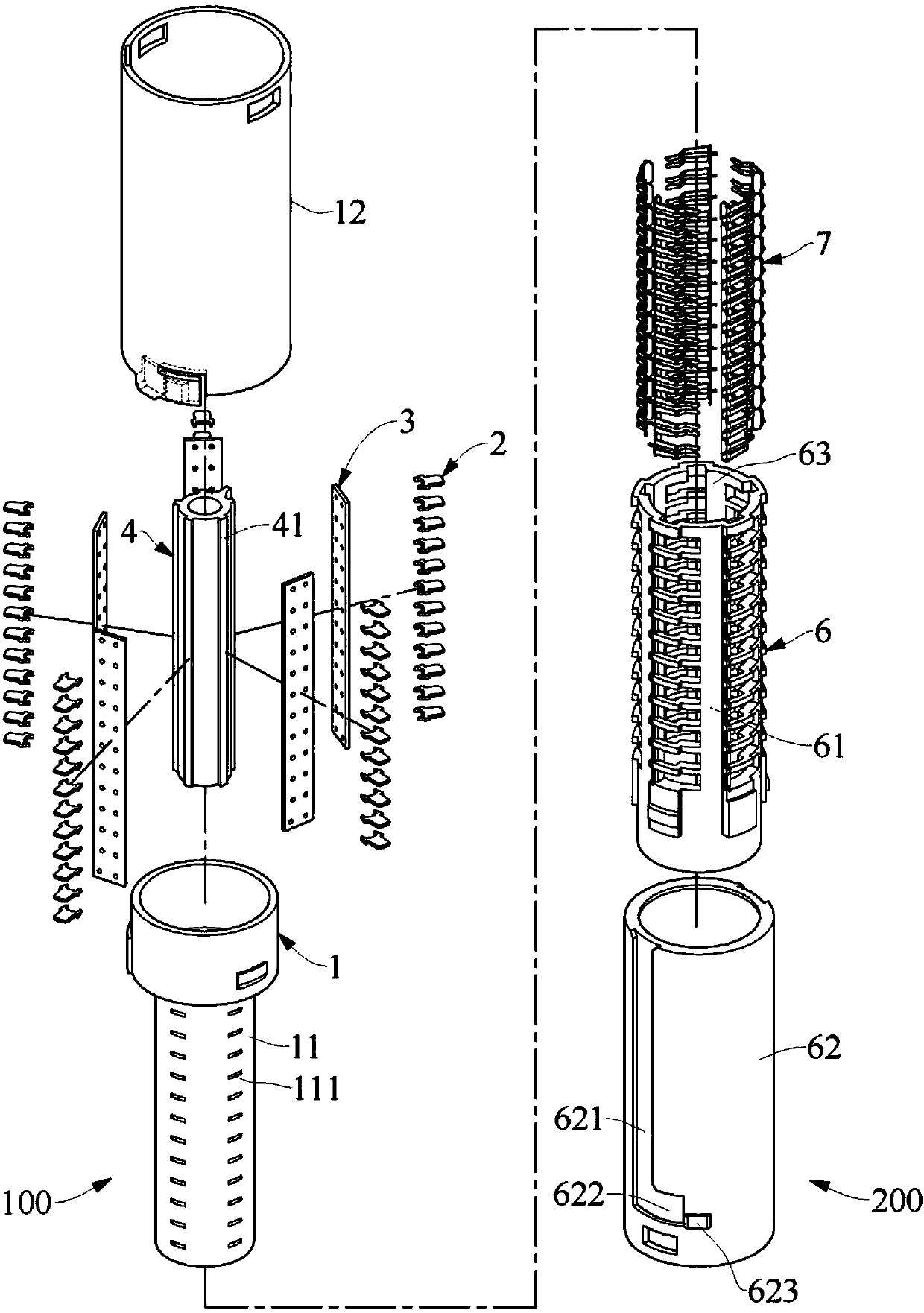

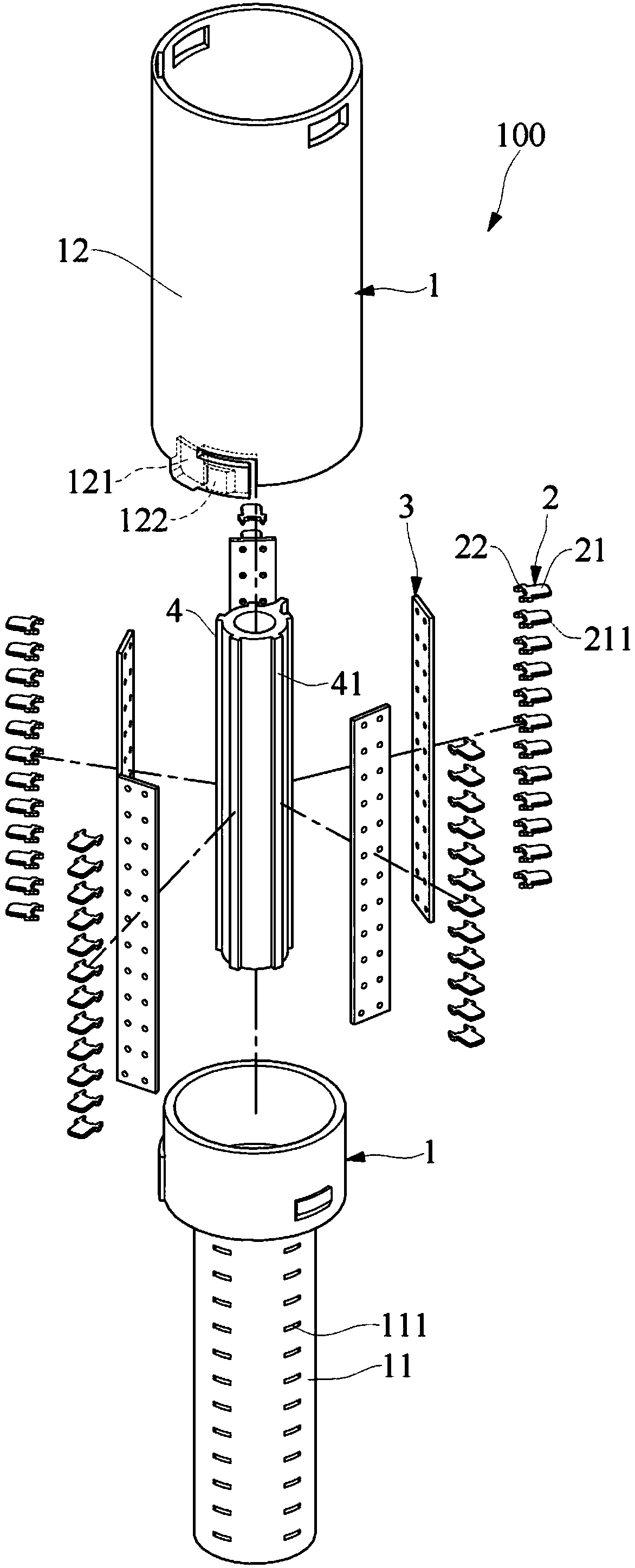

Automatic detection system for ball cage holder

The invention discloses an automatic detection system for a ball cage holder, and the system comprises a rack, a sucking disc, a measuring head support, a camera, a camera support, a sliding seat, a sliding rail, a sliding seat cylinder, measuring tools, and a main control machine. During measurement, the sucking disc absorbs the holder, and the sliding seat cylinder pushes the sliding seat to enable the holder to move to a measurement position. The holder is positioned in a movement process, and the two measuring tools achieve one-time precision measurement. Meanwhile, the camera also achieves the precision detection of the holder. Afterwards, the sliding seat cylinder pushes the sliding seat to enable the holder to be separated from the measuring jaws of the two measuring tools. A sucking disc transmission device drives the holder to rotate twice, and the camera achieves the precision detection of the distance between two adjacent holes of the holder. The above process is carried out twice, thereby completing the detection of the holder.

Owner:ZHEJIANG UNIV OF TECH

Multi-kinetic energy tactile sensor and measuring method

ActiveCN107238452ASimple structureMiniaturizationForce measurement using piezo-resistive materialsApparatus for force/torque/work measurementContact forceHardness

The invention discloses a multi-kinetic energy tactile sensor and a measuring method. The multi-kinetic energy tactile sensor is composed of a hardness detecting unit, a voltage-sensitive varistor sheet, a rubber pipe and a connector. The hardness detection unit is intended for detecting the hardness of a tissue which is in contact with the end of an instrument. The voltage-sensitive varistor sheet is intended for detecting the contact force when the end of the instrument and side wall is in contact with an tissue or blood vessel. Compared with prior art, according to the invention, the multi-kinetic energy tactile sensor is advantaged by capability of detecting tissue hardness, and the contact force of the end of the instrument and the side wall, having simple structure, being beneficial to minimization, being free from contact force upon detecting hardness, and being applied to hardness measurement of biological tissues. The tactile sensor can provide safety in the field of interventional operation, provide key information for disease diagnosis of biological tissues, and can facilitate the development in the field of interventional operation.

Owner:江苏有熊安全科技有限公司

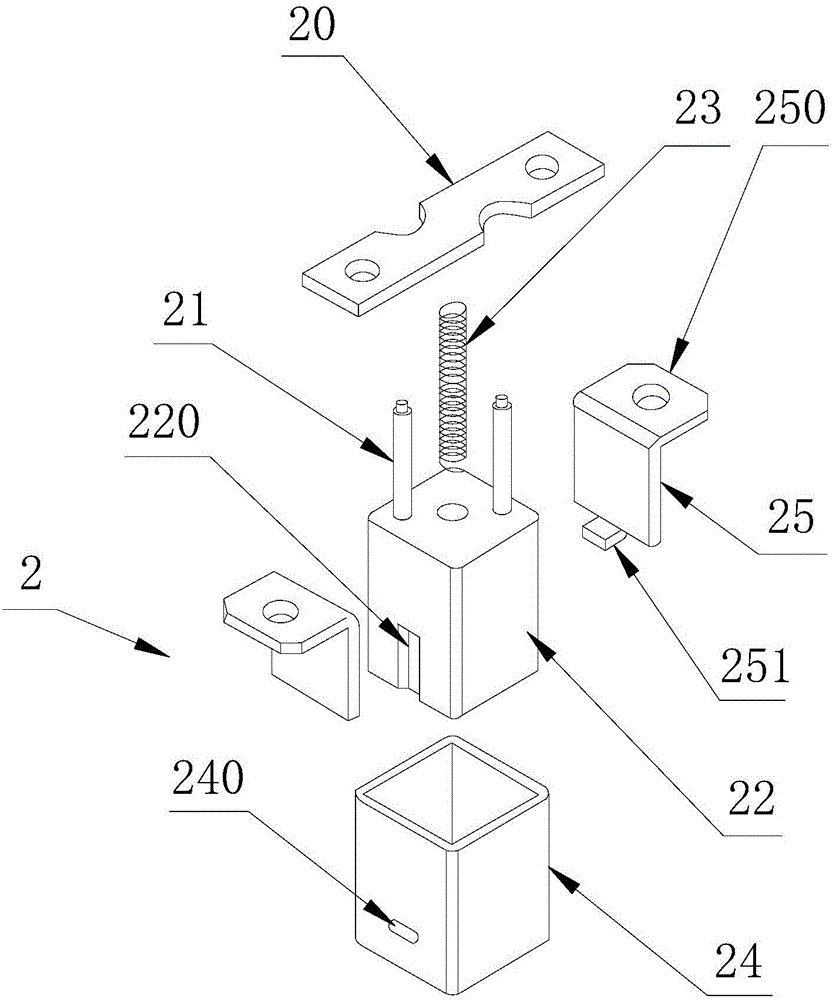

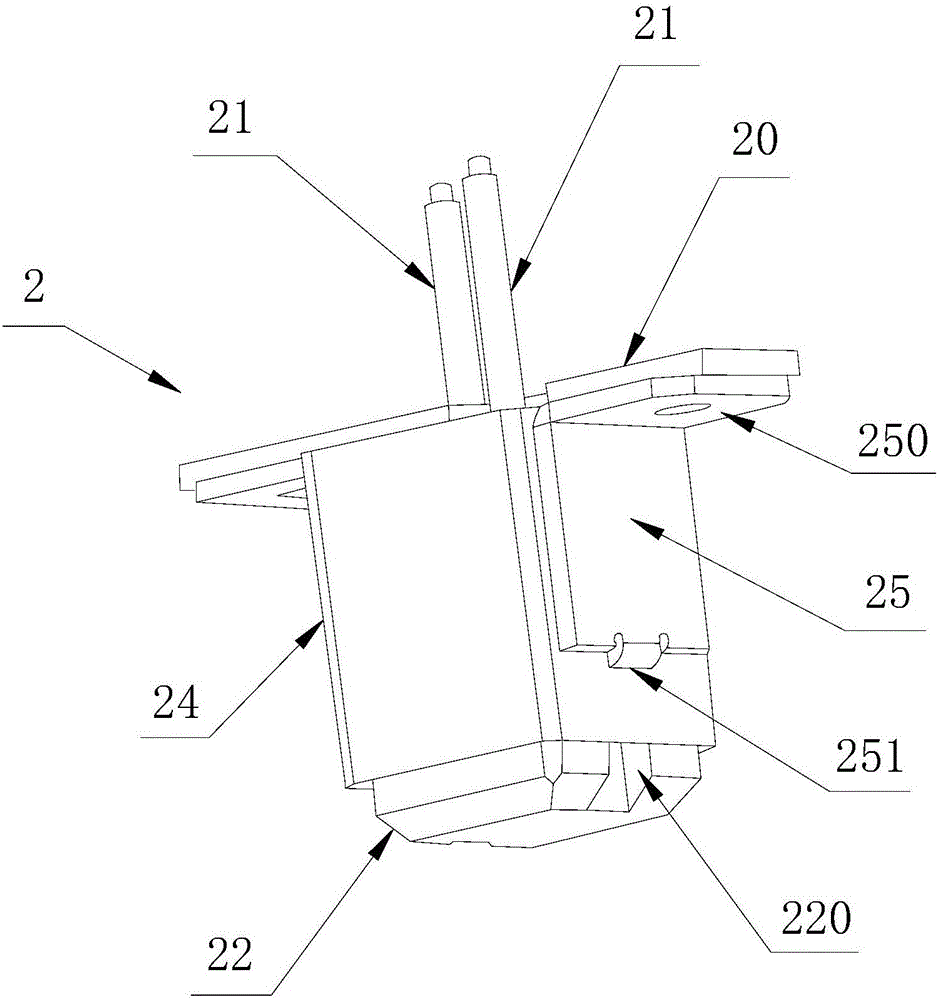

AGV battery charging device

ActiveCN106026281AIncrease charging flexibilityImprove efficiencyBatteries circuit arrangementsElectric powerBattery chargeIn vehicle

The invention discloses an AGV (Automated Guided Vehicle) battery charging device which includes a male charging head provided on the AGV and electrically connected to a vehicle mounted battery and a female charging head provided at an AGV charging station and electrically connected to the power source of the power charging station wherein the male charging head consists of two brush blocks connected with the positive pole and negative pole of the vehicle mounted battery respectively. The female charging head also consists of a brush plate arranged on an AGV guide rail or on a ground or a support next to the guide rail. The brush plate comprises an insulating substrate and two conductive plates fixedly arranged on the insulating substrate and connected respectively to the positive pole and the negative pole of the power source of the AGV charging station. The two conductive plates are in electric contact with the two brush blocks to charge the vehicle mounted battery of the AGV. With the charging device provided by the invention, it is possible to realize on-line charging of an AGV without human intervention, and the process is a quick and automatic one to greatly improve the charging flexibility of the AGV and the using efficiency of the AGV.

Owner:SHANGHAI HUAXIN MINFU ELECTRICAL TECH

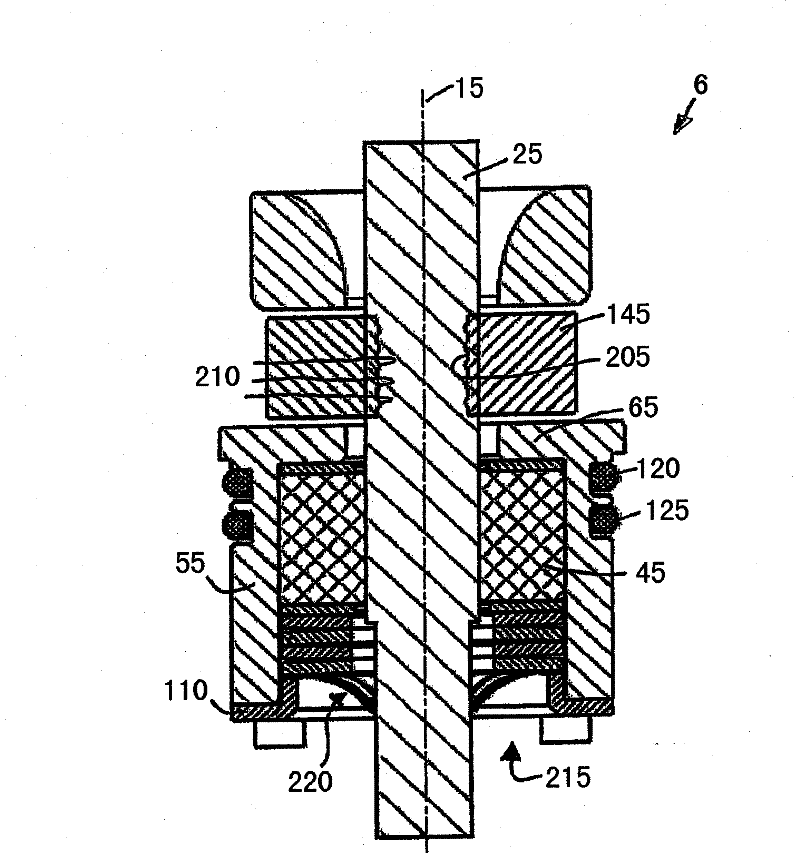

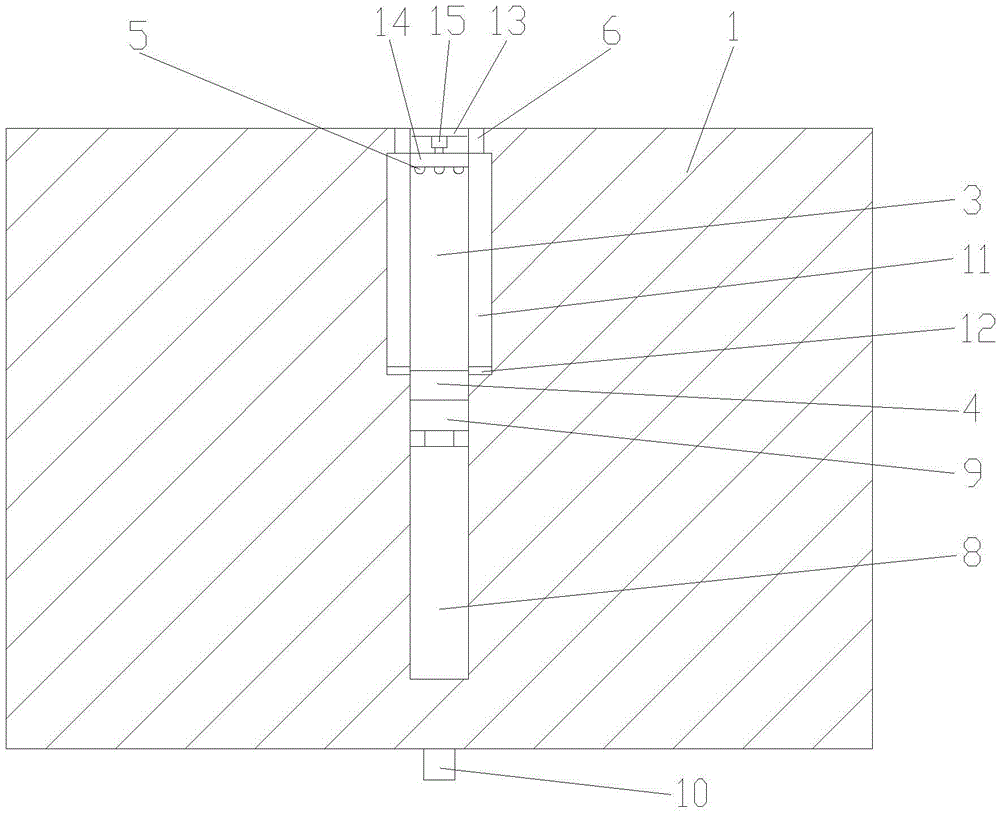

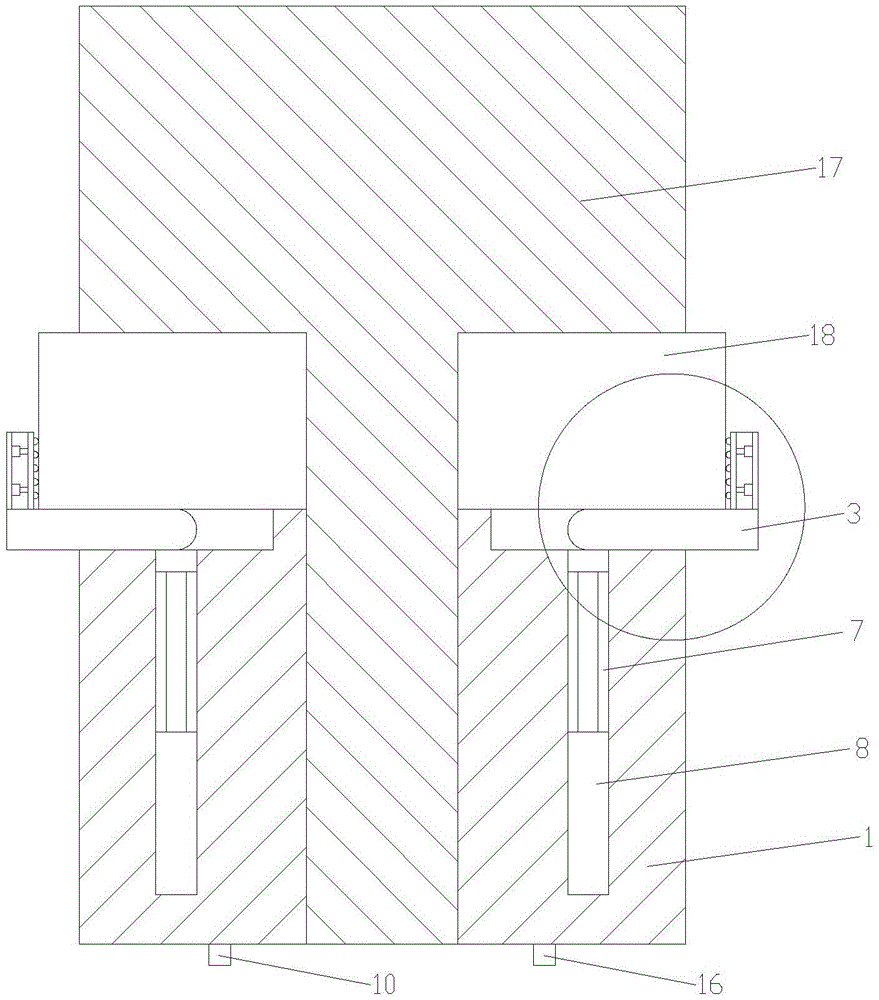

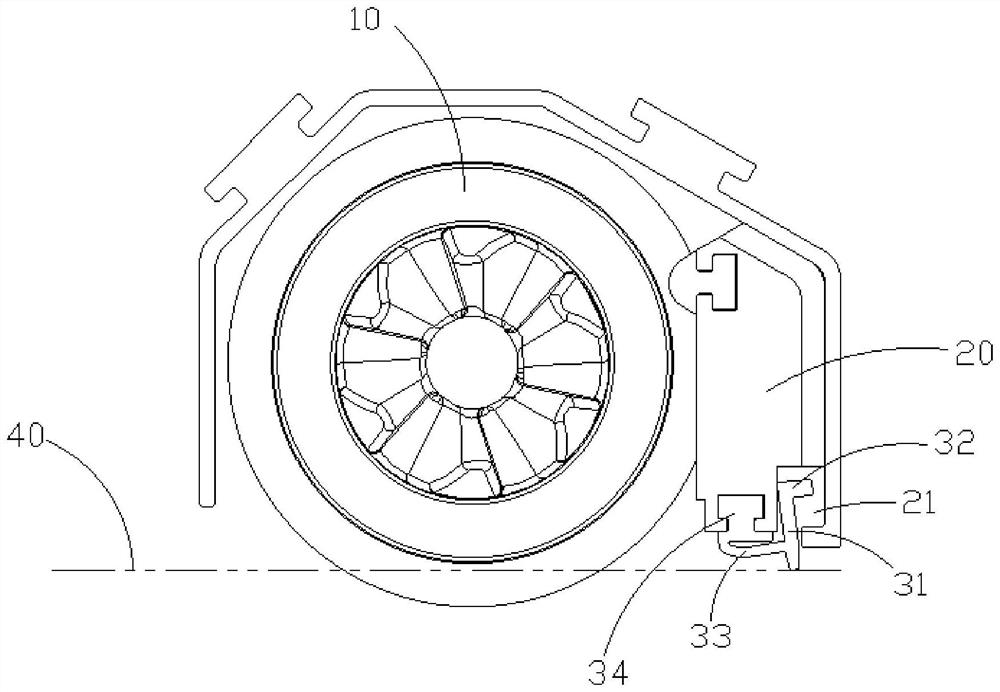

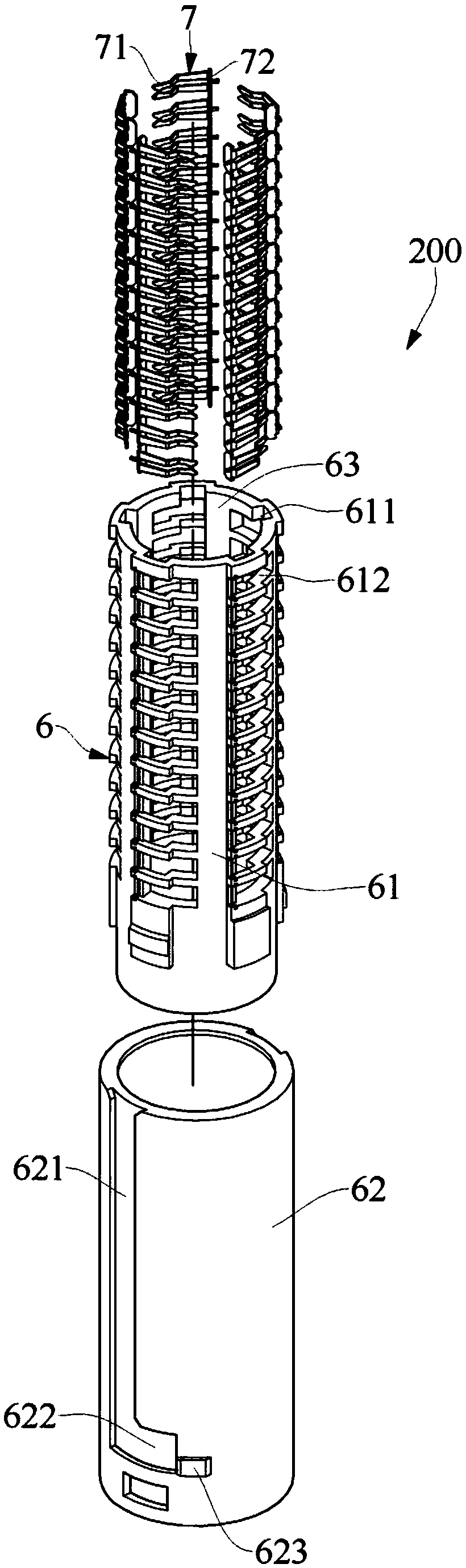

Immersion motor

ActiveCN102204047AGuaranteed contact forceSupports/enclosures/casingsEngineeringMechanical engineering

Owner:GRUNDFOS MANAGEMENT AS

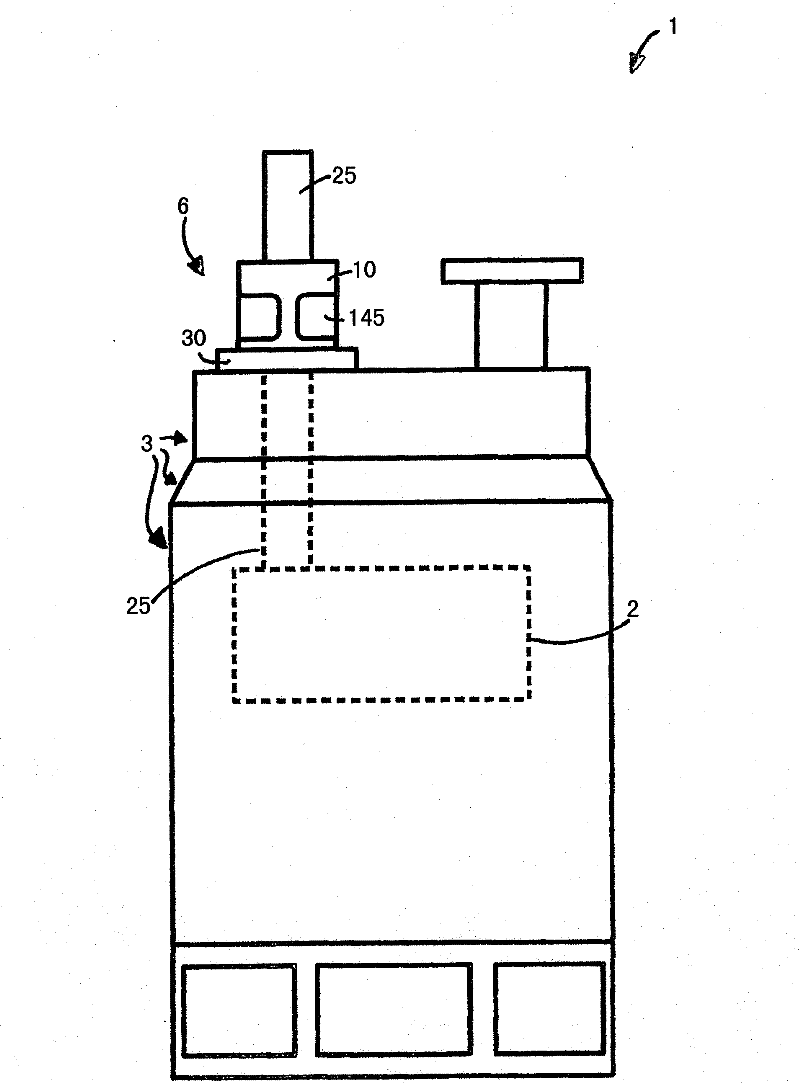

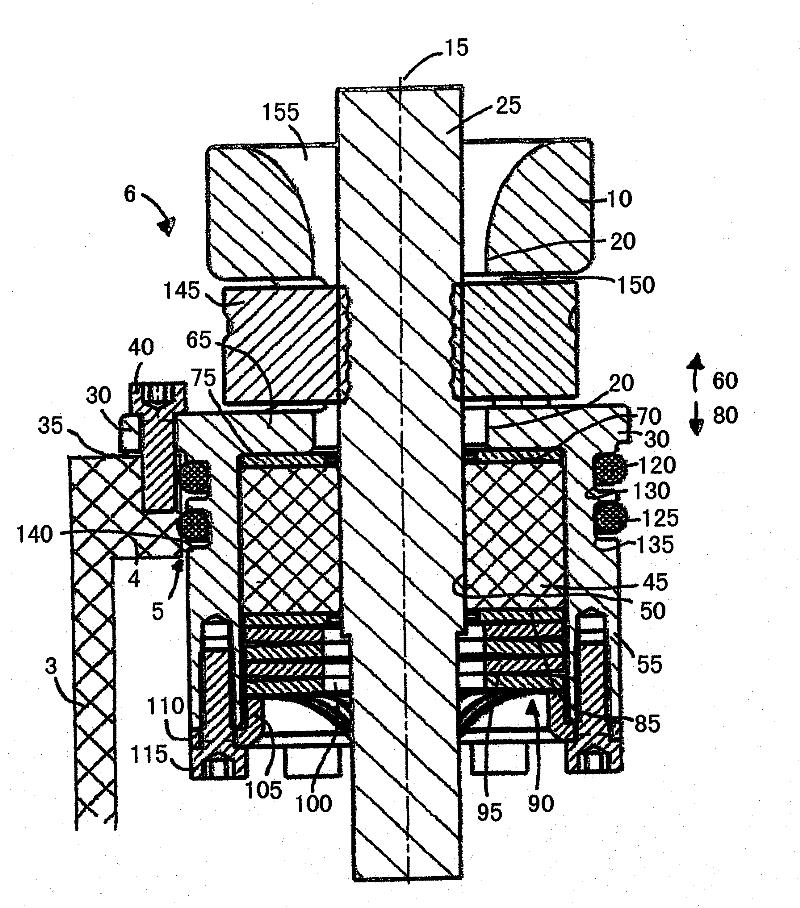

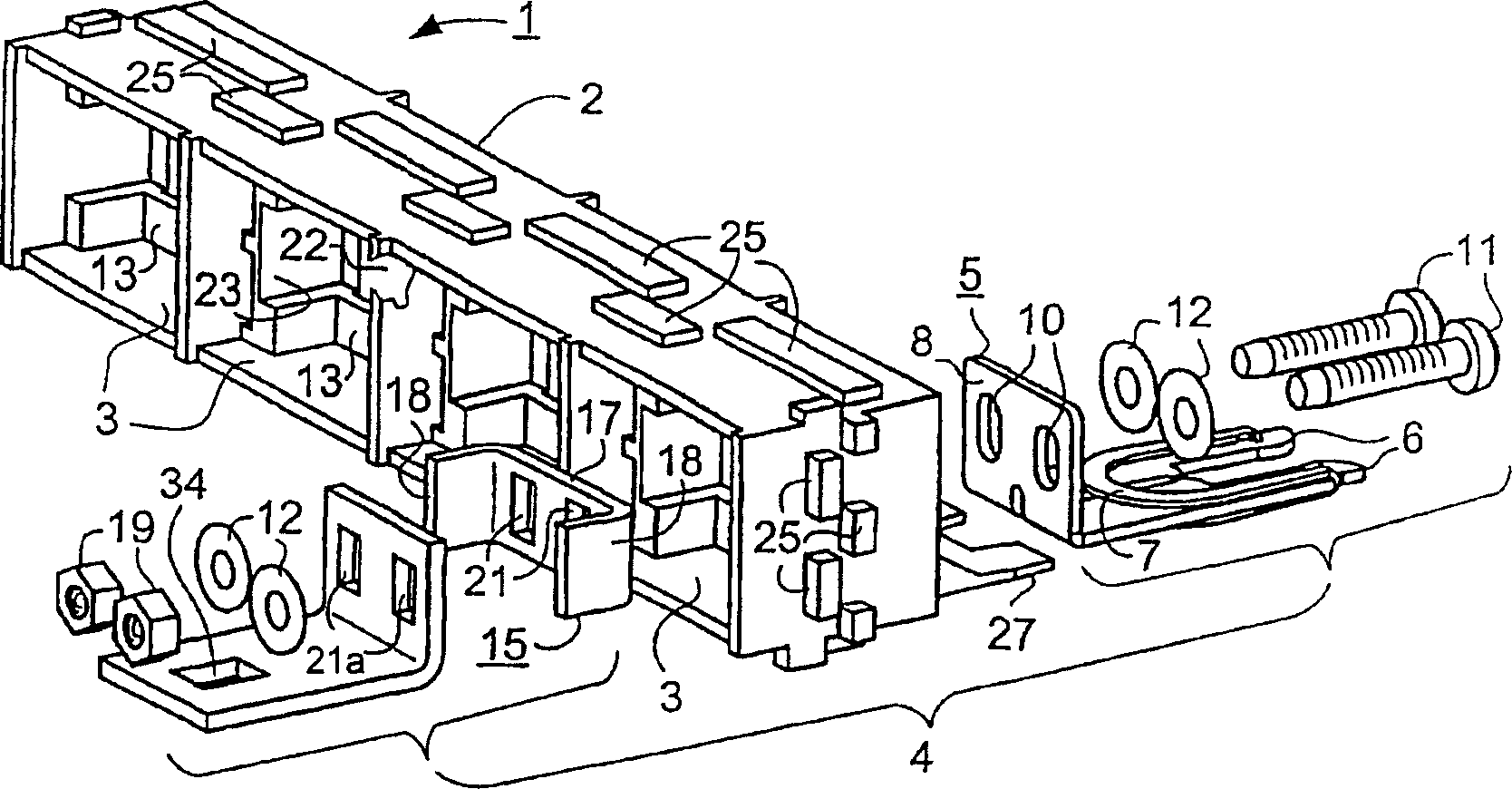

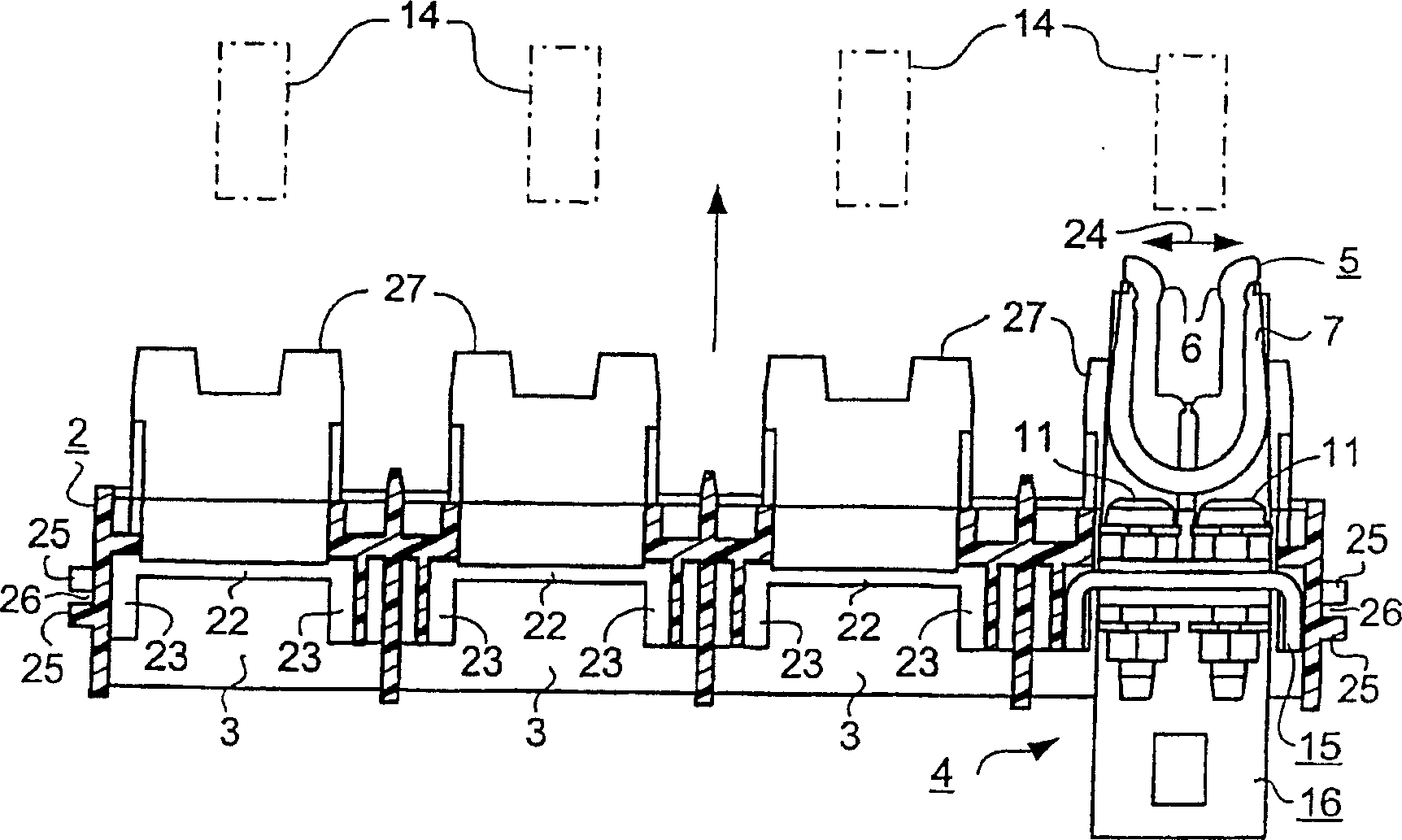

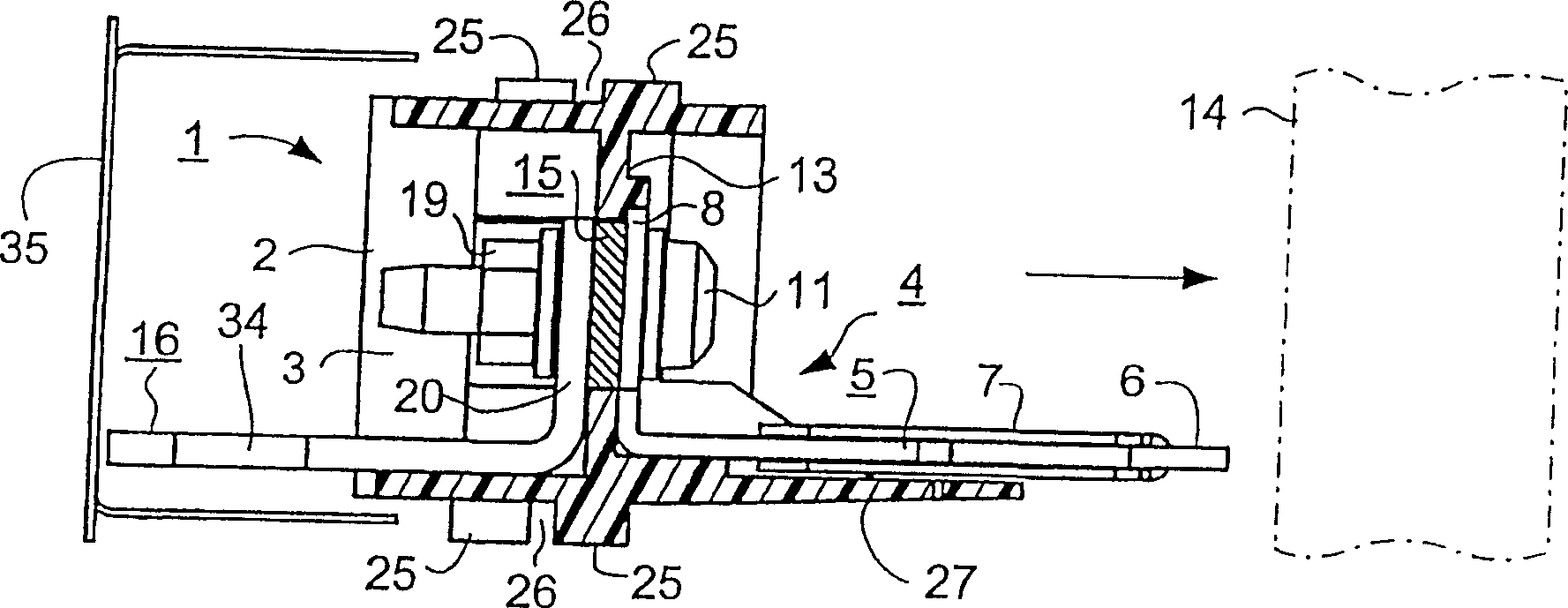

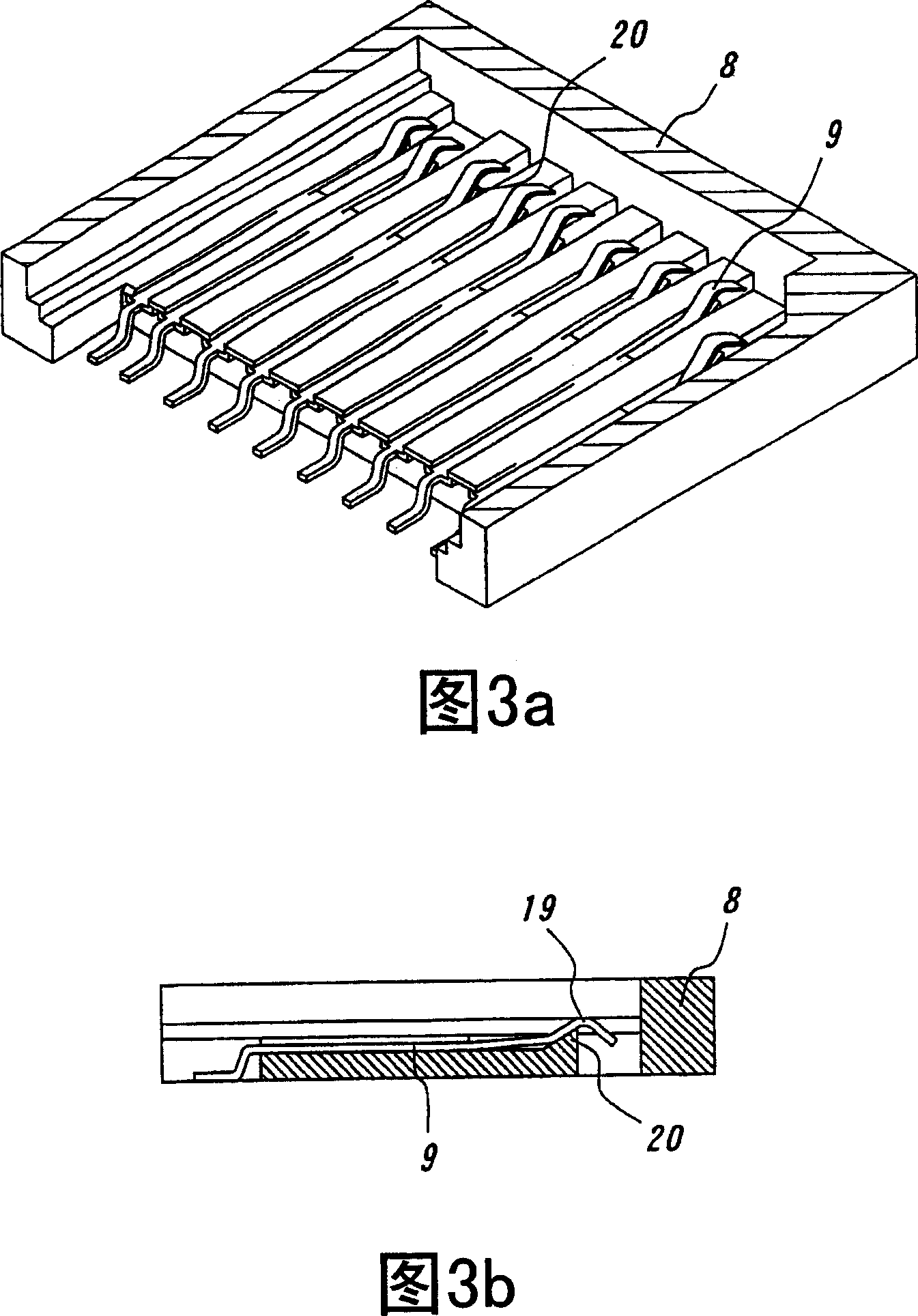

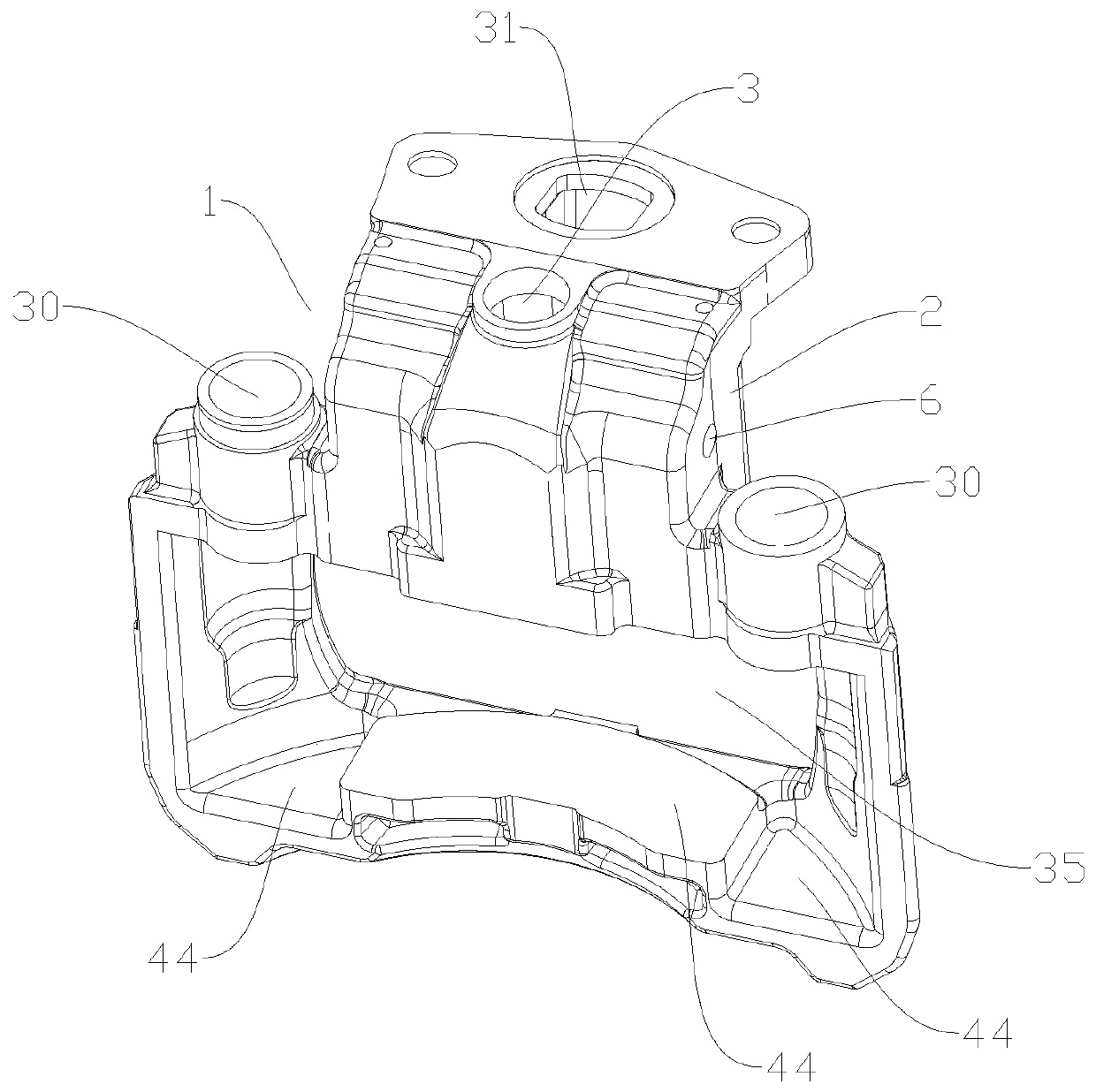

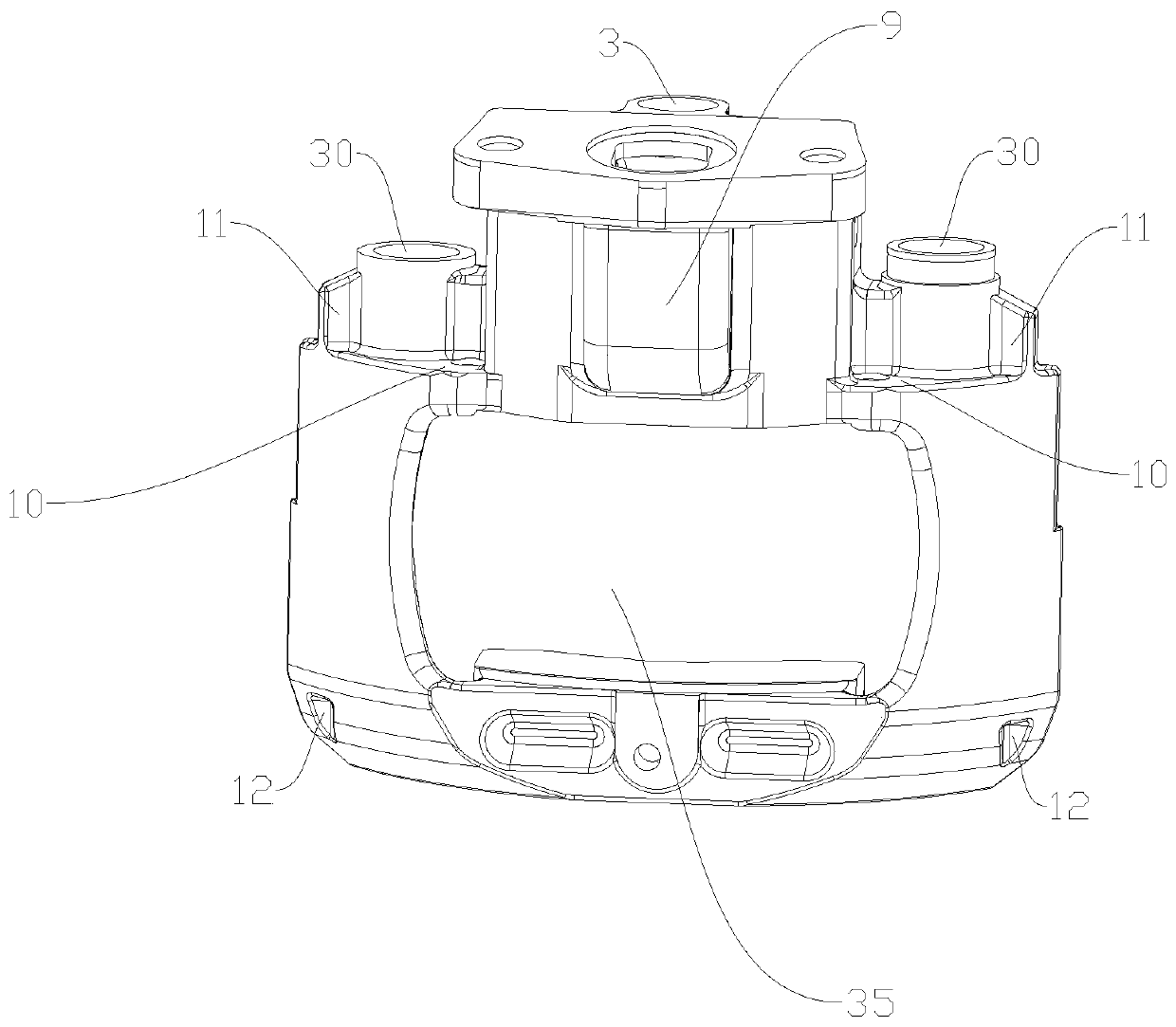

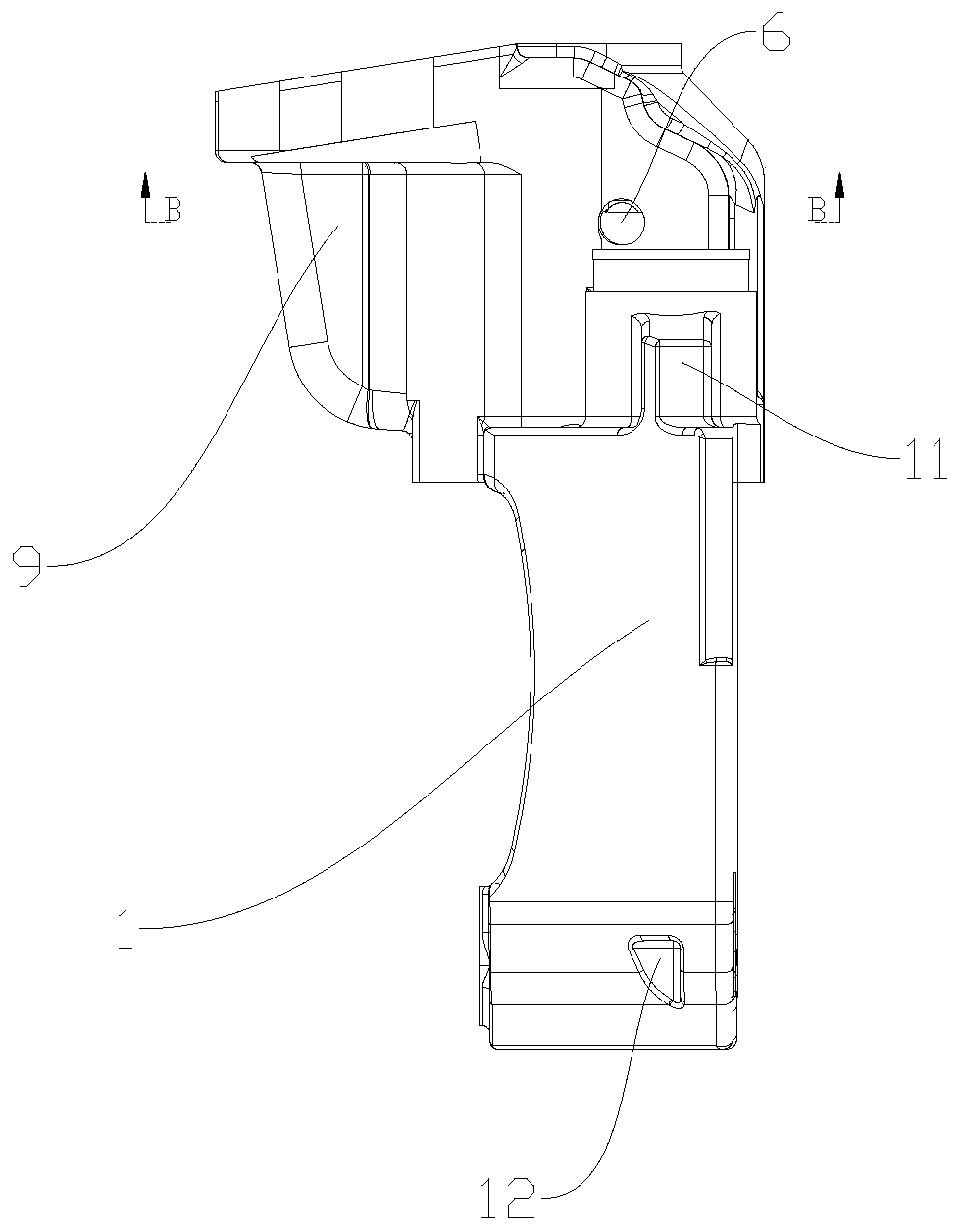

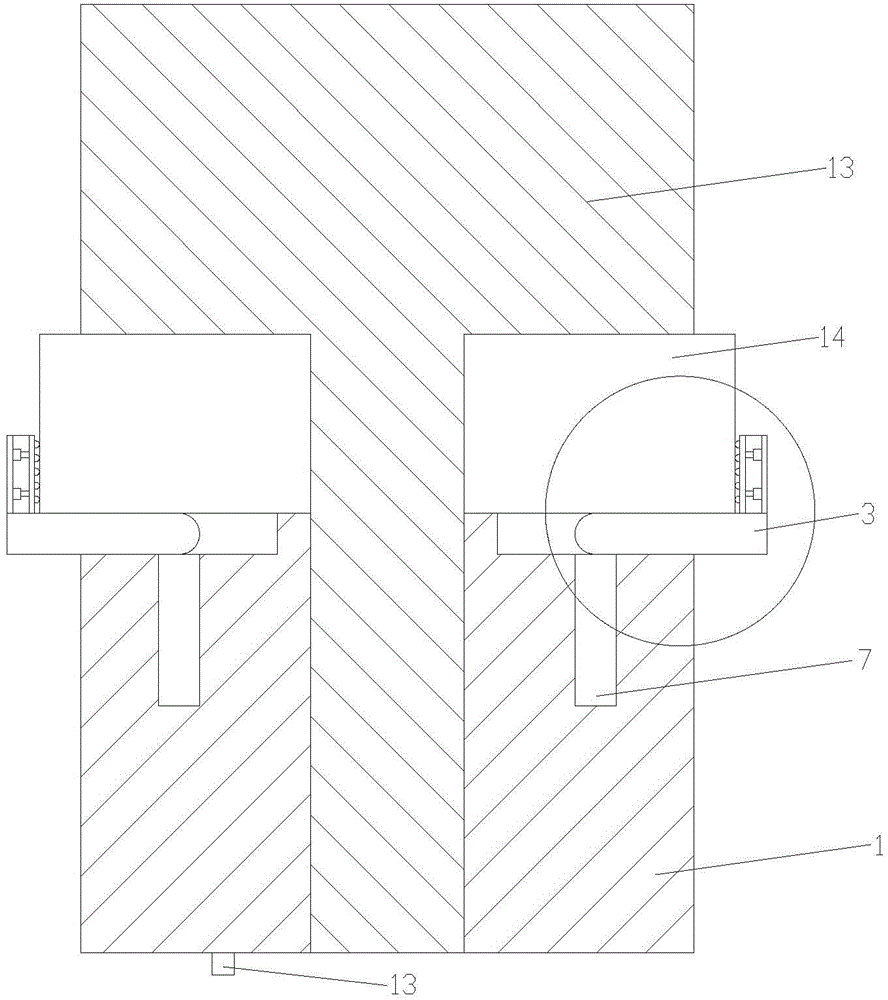

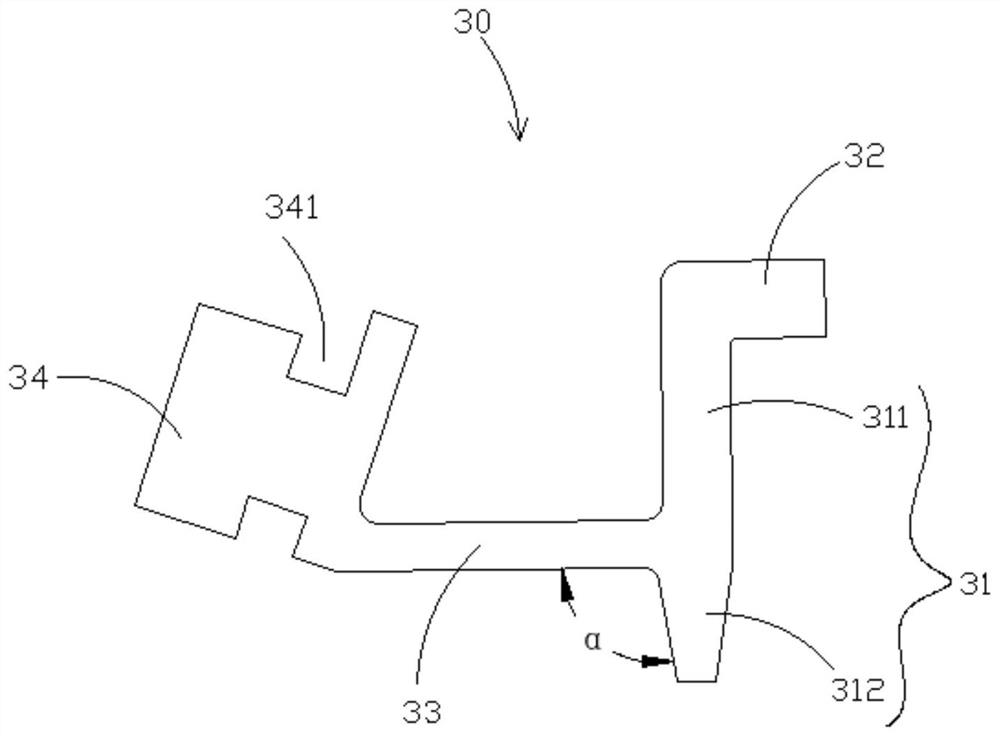

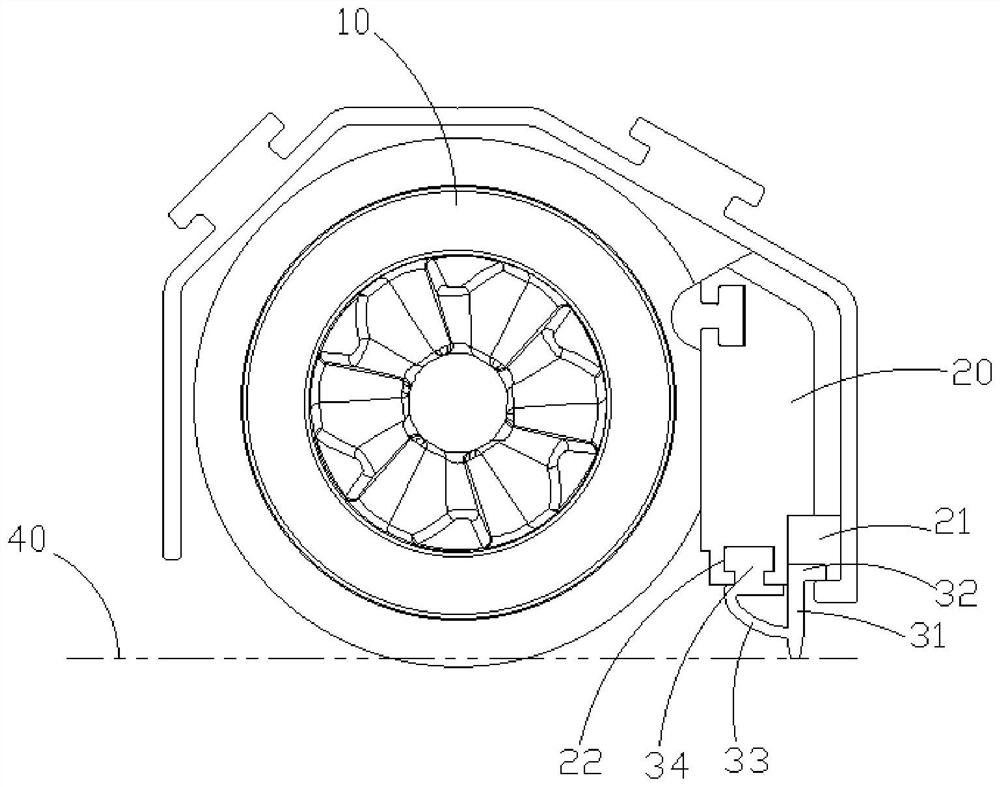

Contact device for the adapting unit connection of a mobile appliance unit to fixed contact rails

InactiveCN1266812CGuaranteed contact forceBus-bar/wiring layoutsSecuring/insulating coupling contact membersContact forceElectrical and Electronics engineering

The invention relates to a contact device (1) for the detachable connection of a mobile appliance unit (30) to fixed conductor rails (14). Said device comprises a housing (2) consisting of insulating material, and contact units (4) which are housed in chambers (3) of the housing (2). Each contact unit (4) comprises at least one bent contact member (5), a connector part (16) which is likewise bent, and a guiding part (15) which is arranged between the two. An intermediate wall (13) is arranged in the chambers (3) of the housing (2), said wall comprising a window (22) for receiving the guiding part (15). An excessive thickness of the guiding part in relation to the intermediate wall (13), combined with the dimensions of the window (22), enables the contact units (4) to be displaced in the chambers (3) in relation to the housing (2). The contact units (4) can thus be oriented towards fixed conductor rails (14) without influencing the contact force.

Owner:SIEMENS AG

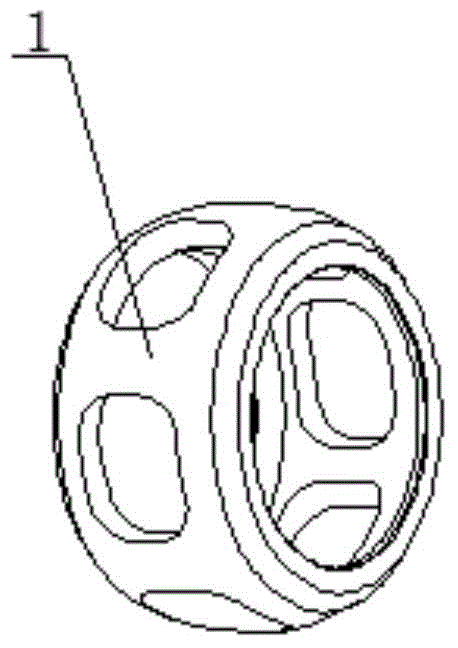

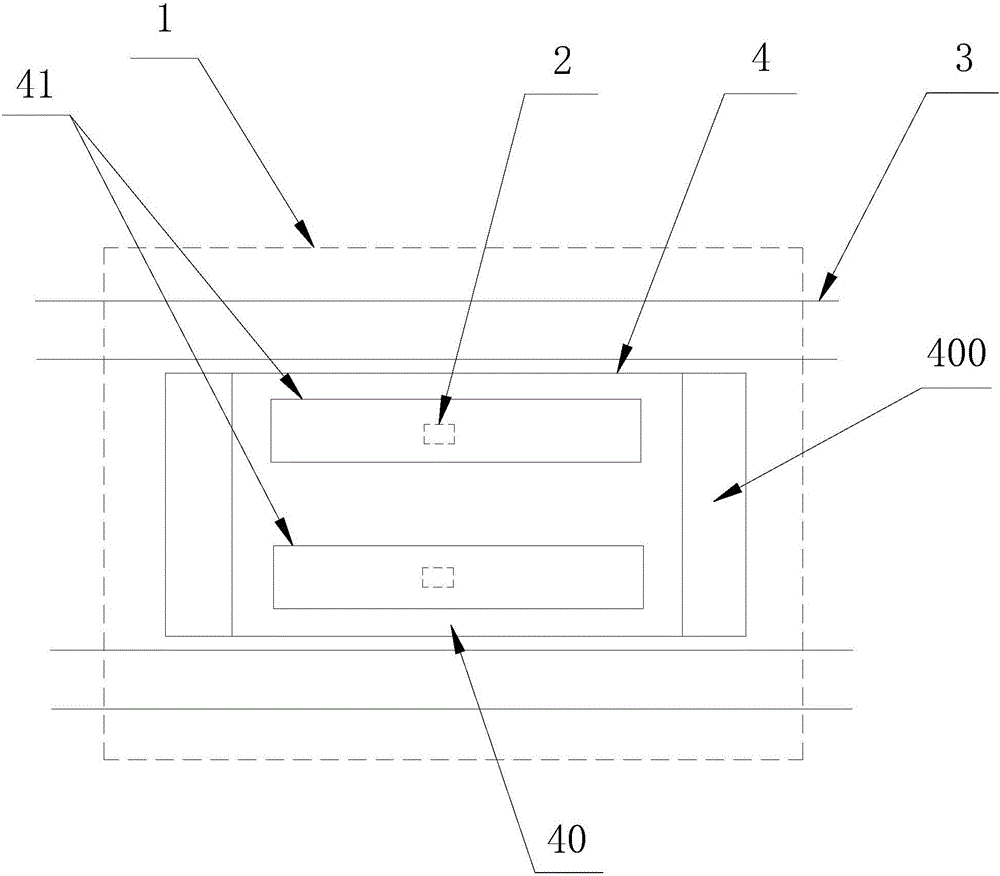

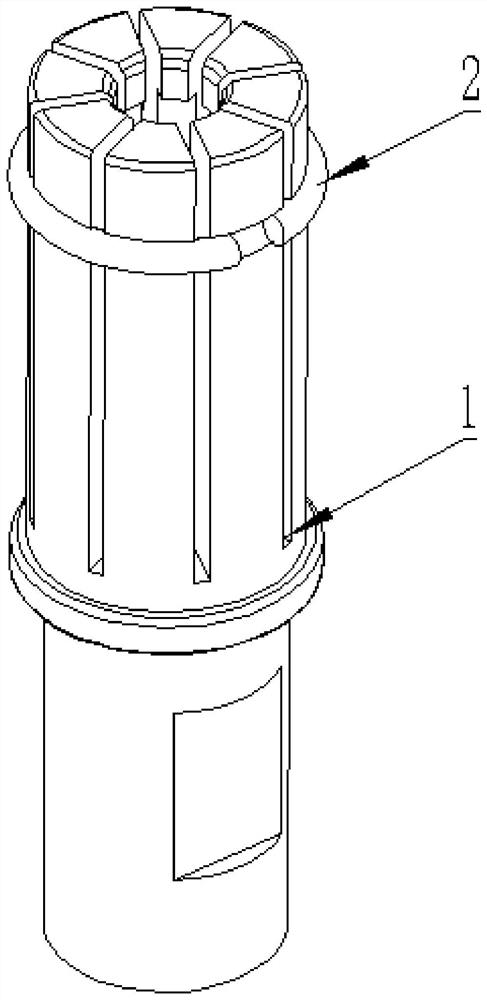

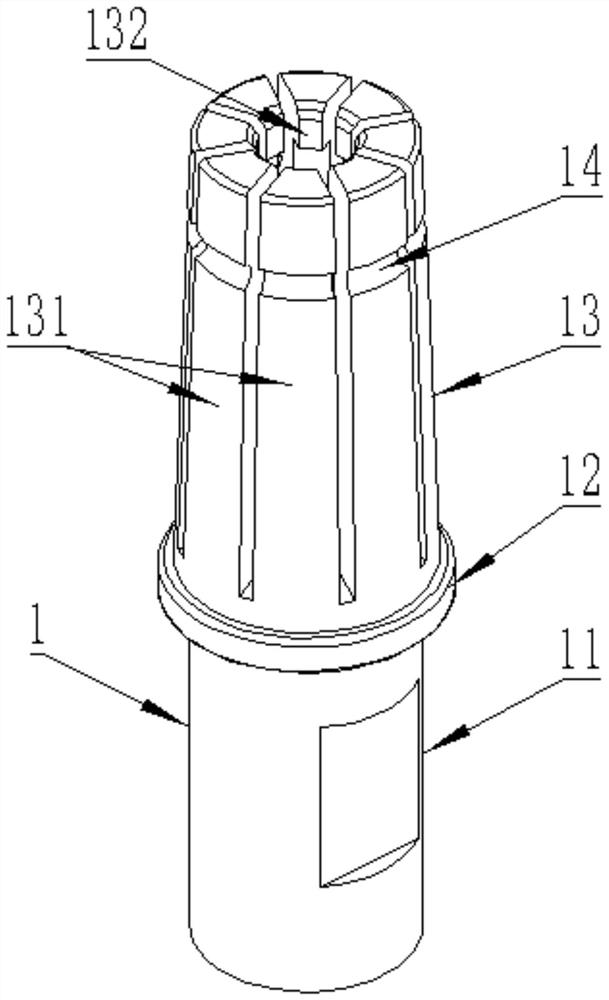

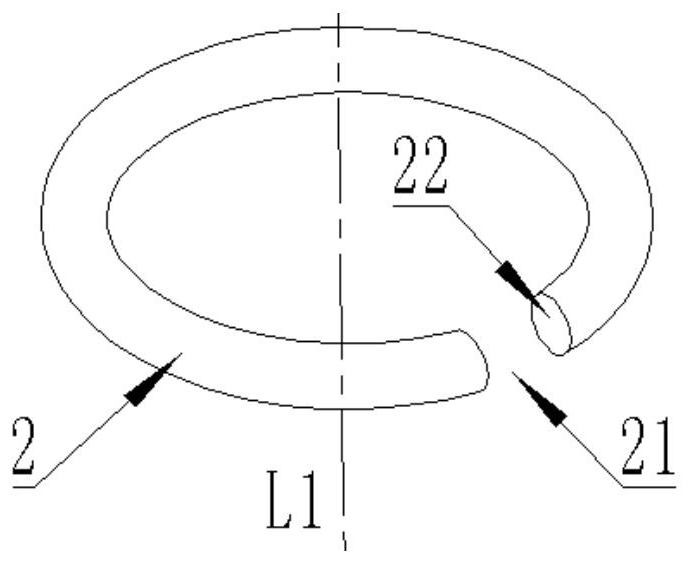

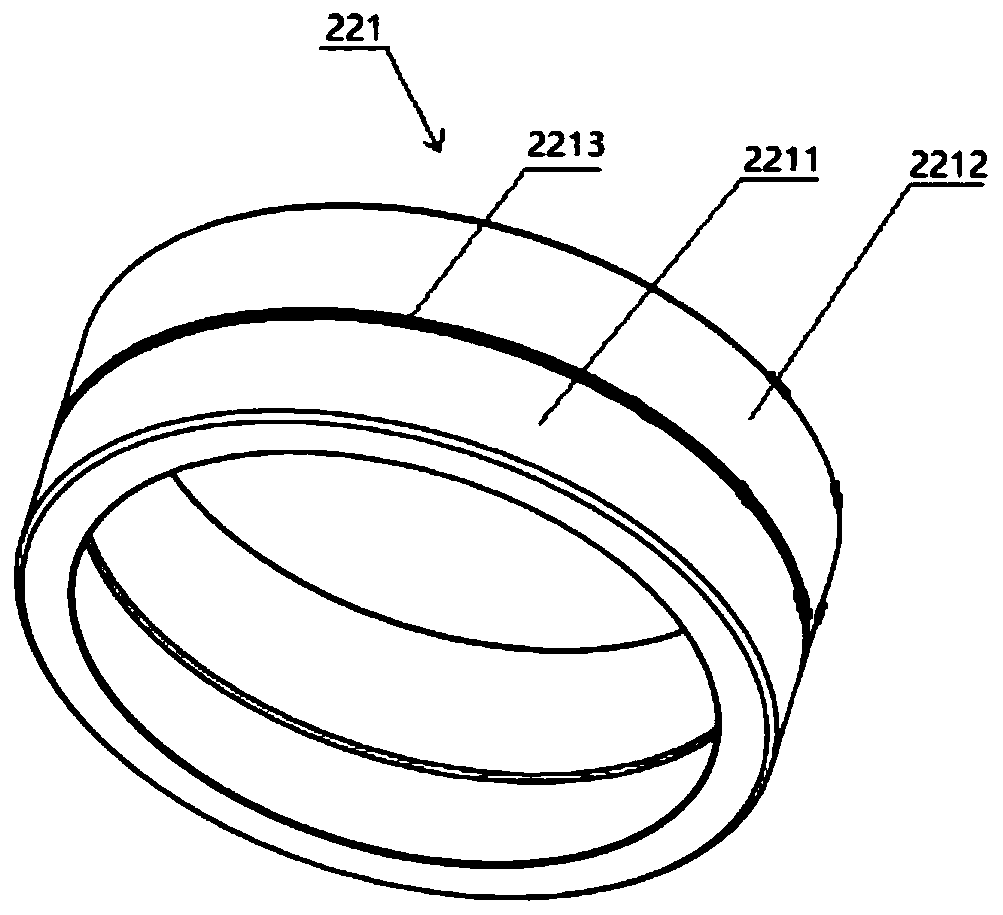

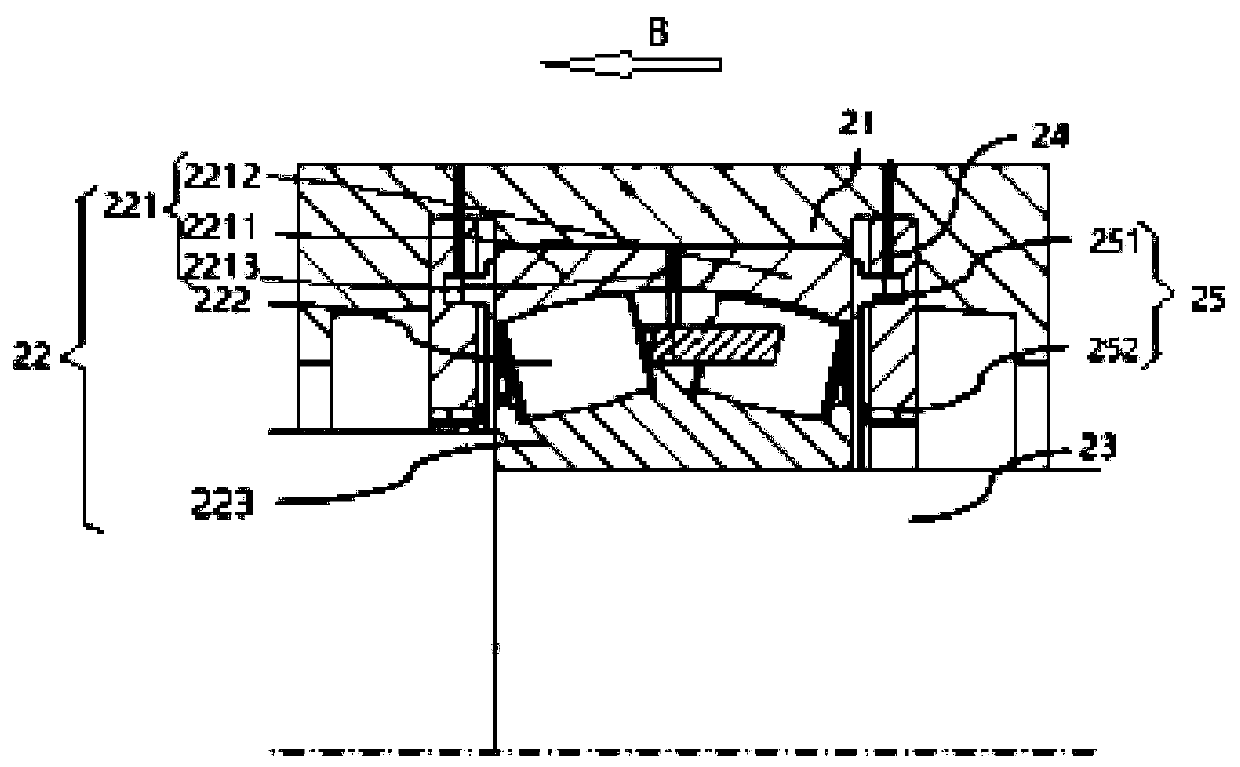

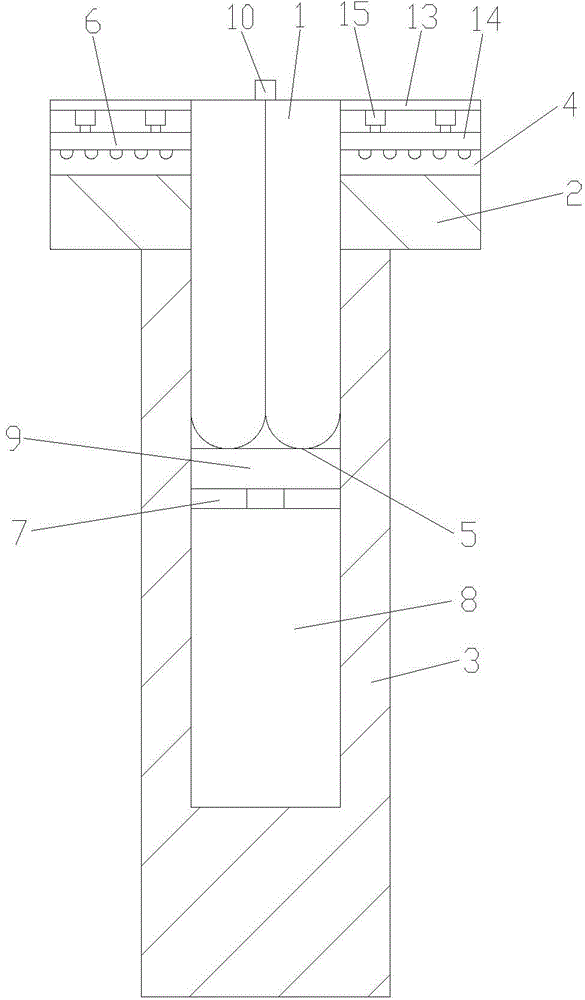

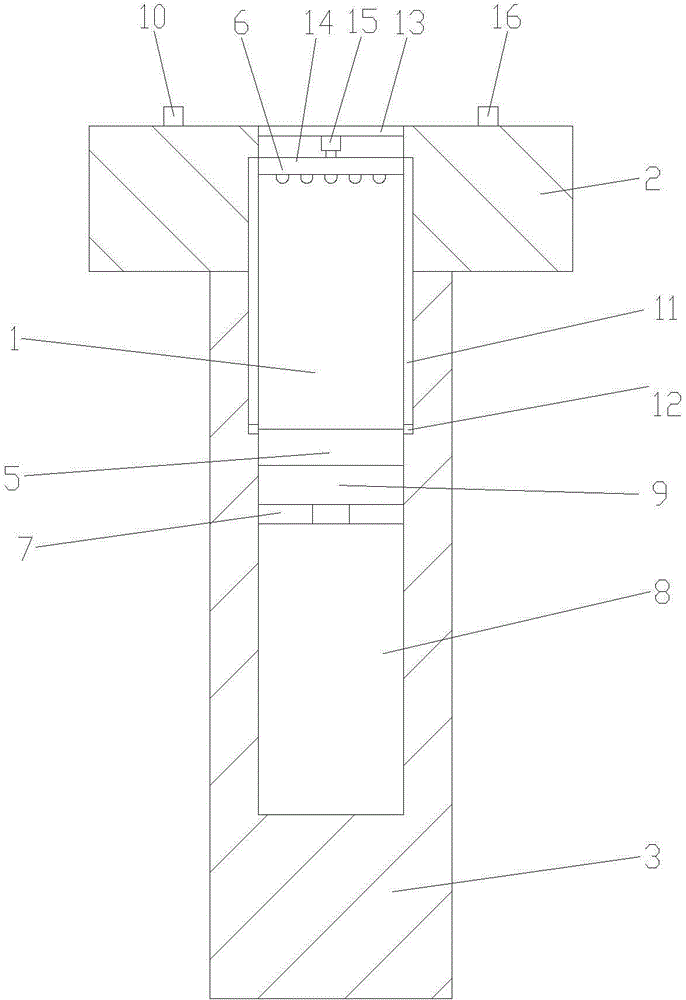

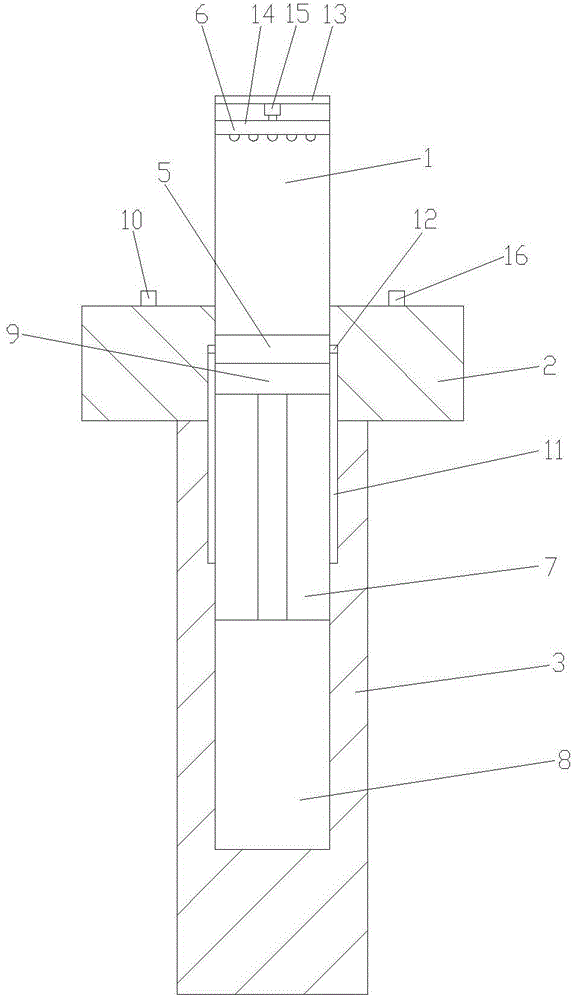

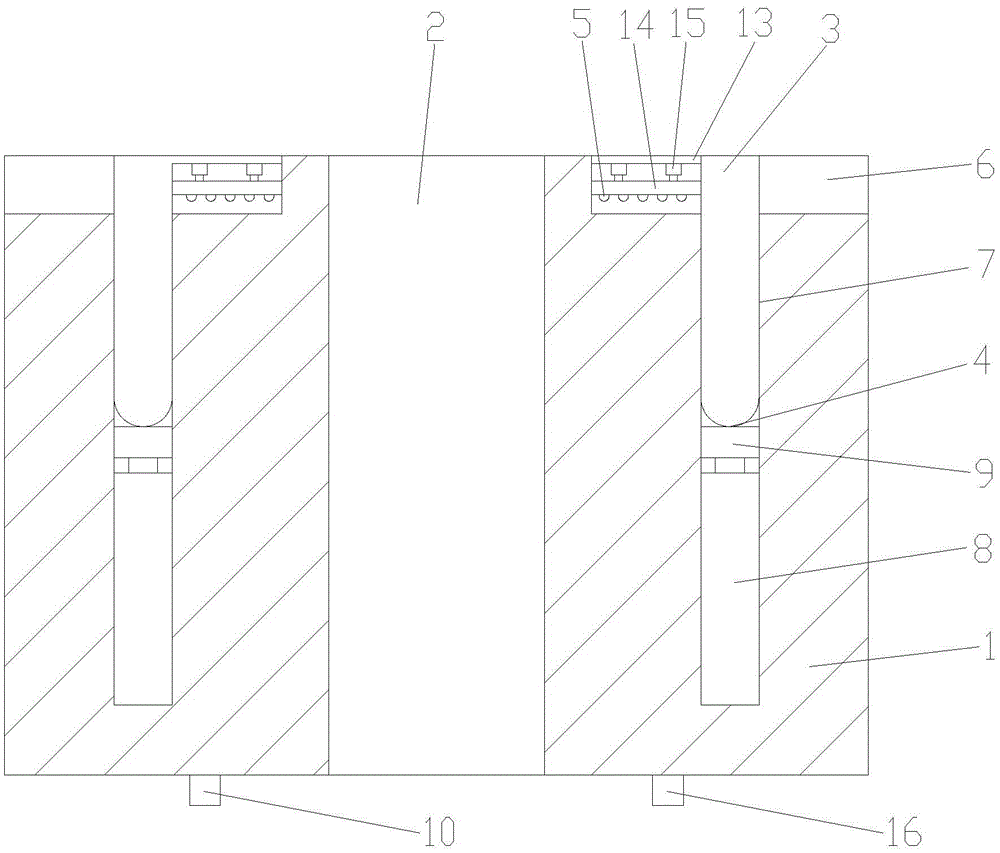

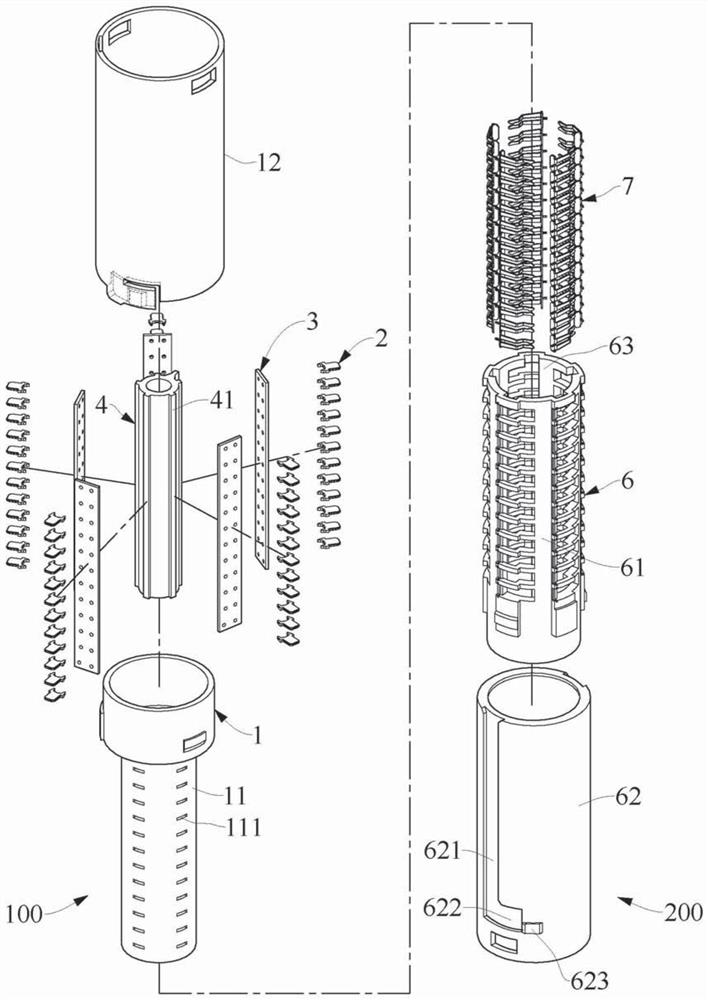

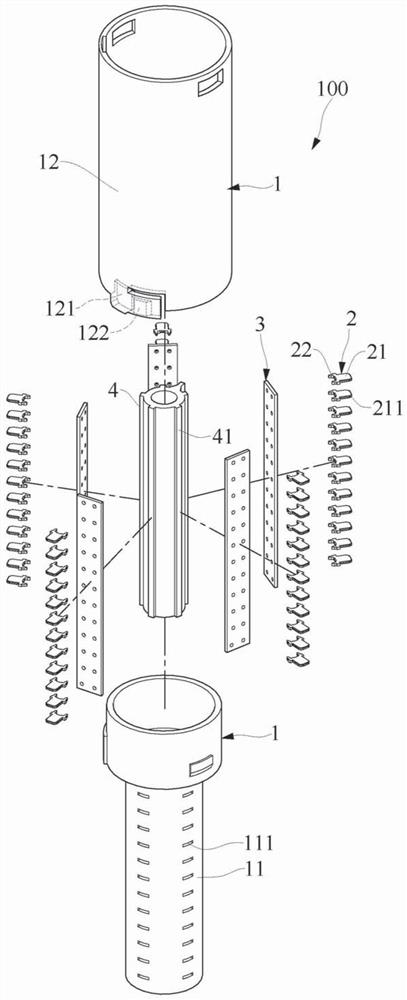

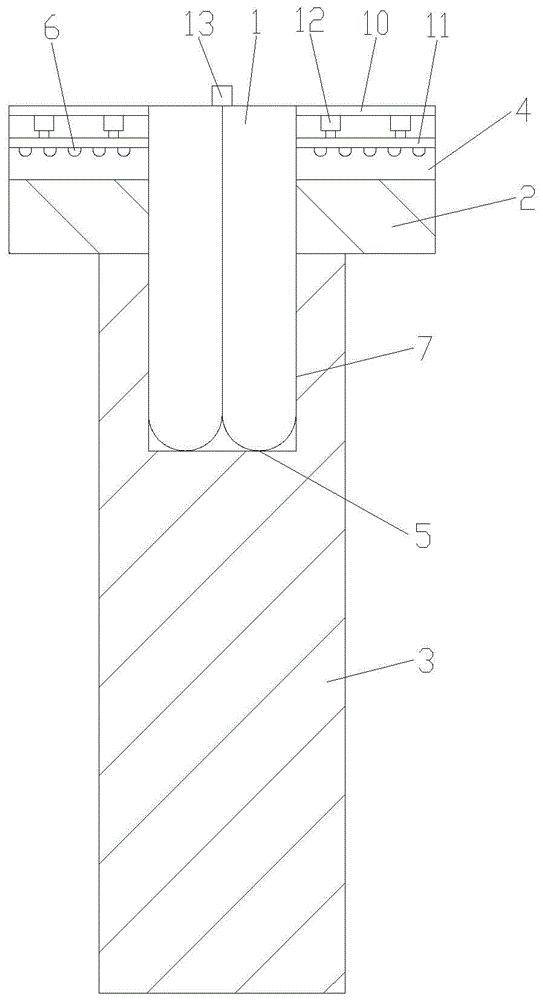

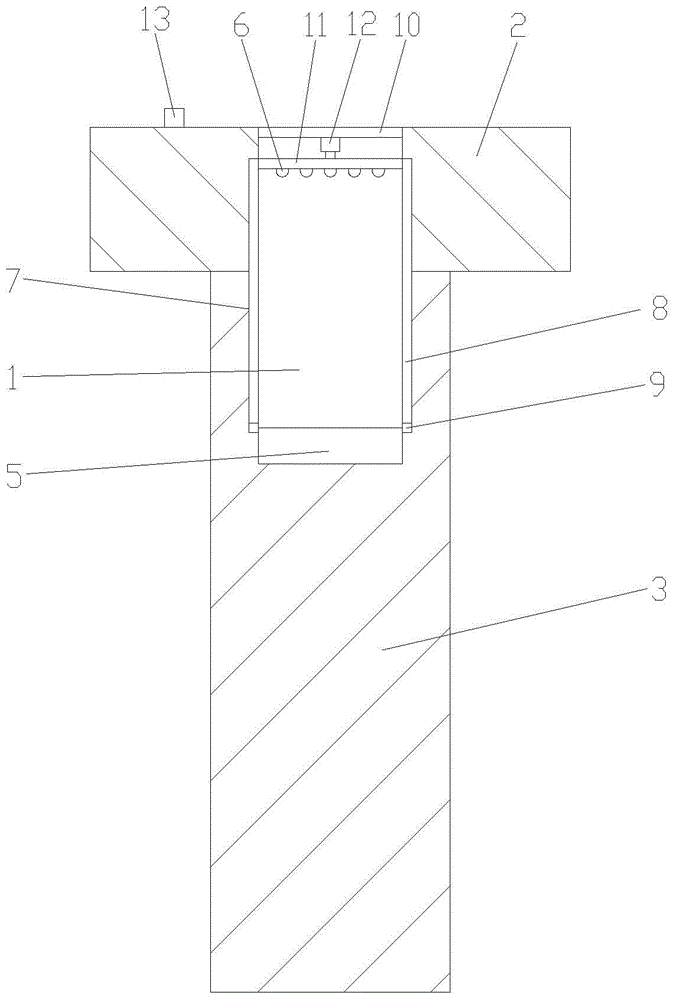

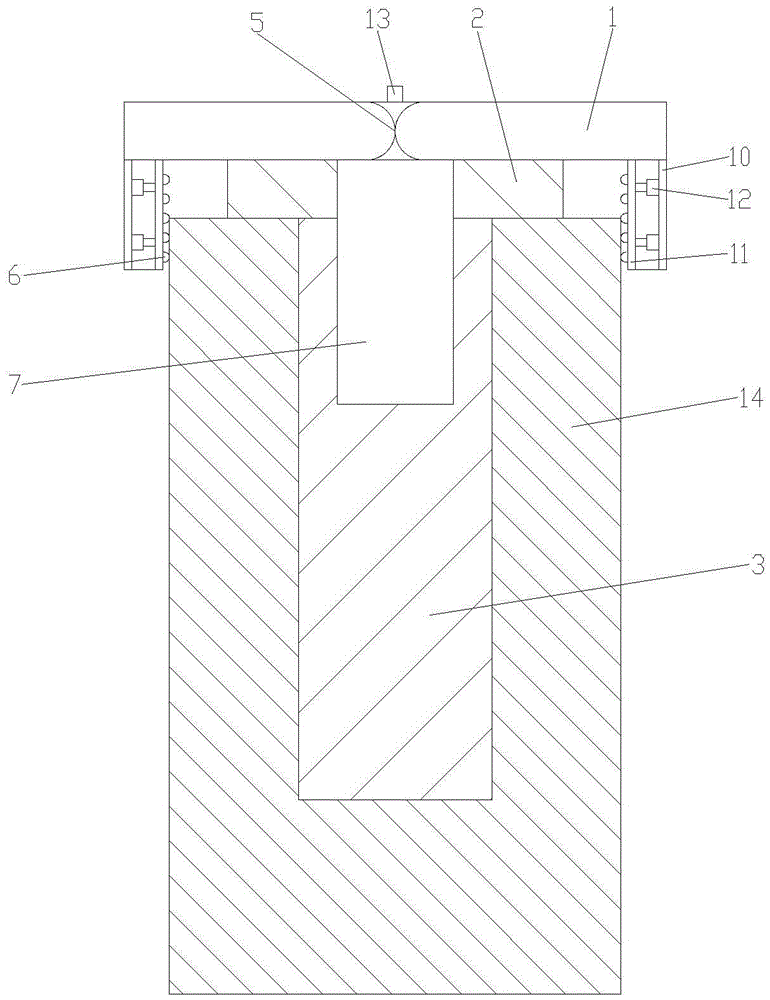

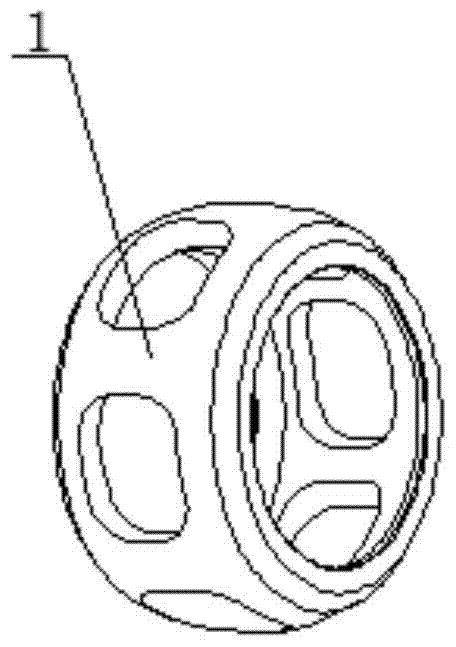

Terminal with memory ring

PendingCN113410683AGuaranteed contact areaGuaranteed contact forceCoupling contact membersStructural engineeringMechanical engineering

The invention provides a terminal with a memory ring. The terminal comprises a terminal body (1) and the memory ring (2); the terminal body (1) comprises a contact section (13); the memory ring (2) is sleeved outside the contact section (13); the memory ring (2) is contacted with the contact section (13); the memory ring (2) is made of memory alloy; and the memory ring (2) can make the contact section (13) contract. The terminal with the memory ring can realize butt joint without insertion force; the contact area and the contact force of the terminal and the matched terminal are ensured through temperature rise during working, so that the contact reliability is improved; and due to the fact that the requirement for the insertion force is omitted, the working is easier, and the working efficiency is improved.

Owner:CHANGCHUN JETTY AUTOMOTIVE PARTS CORP

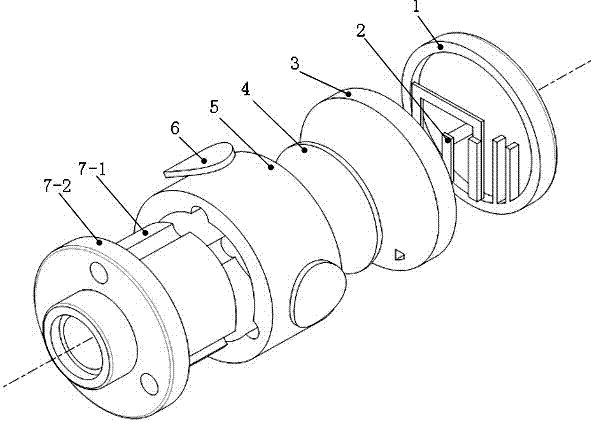

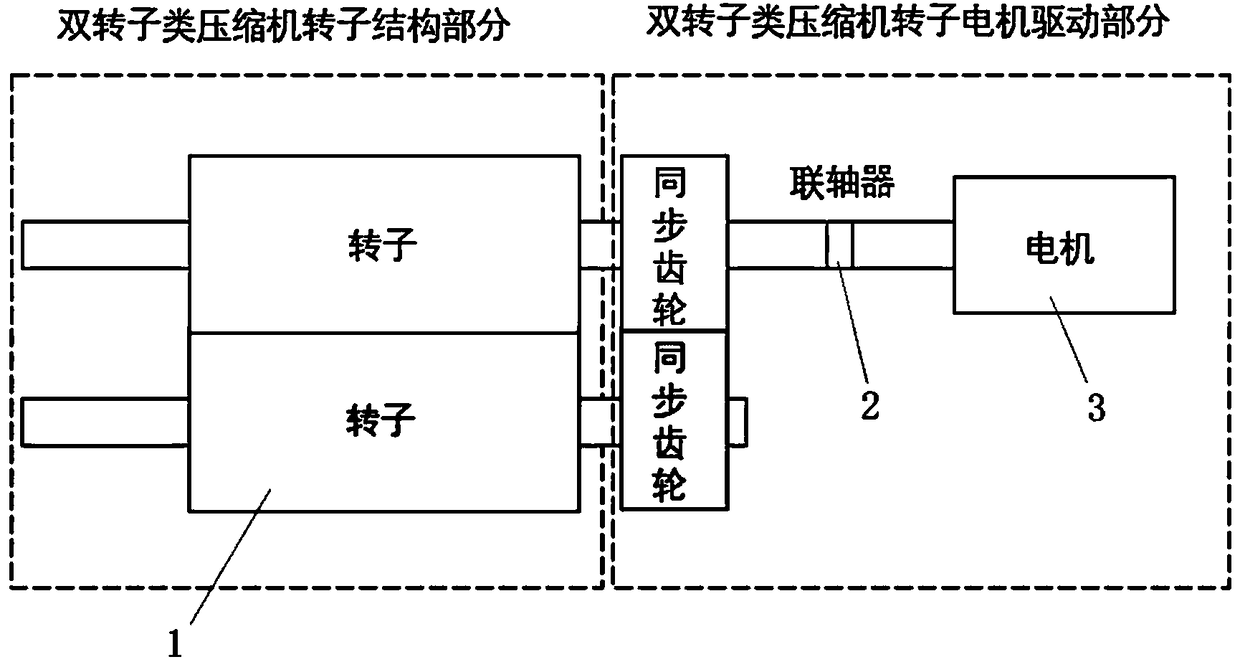

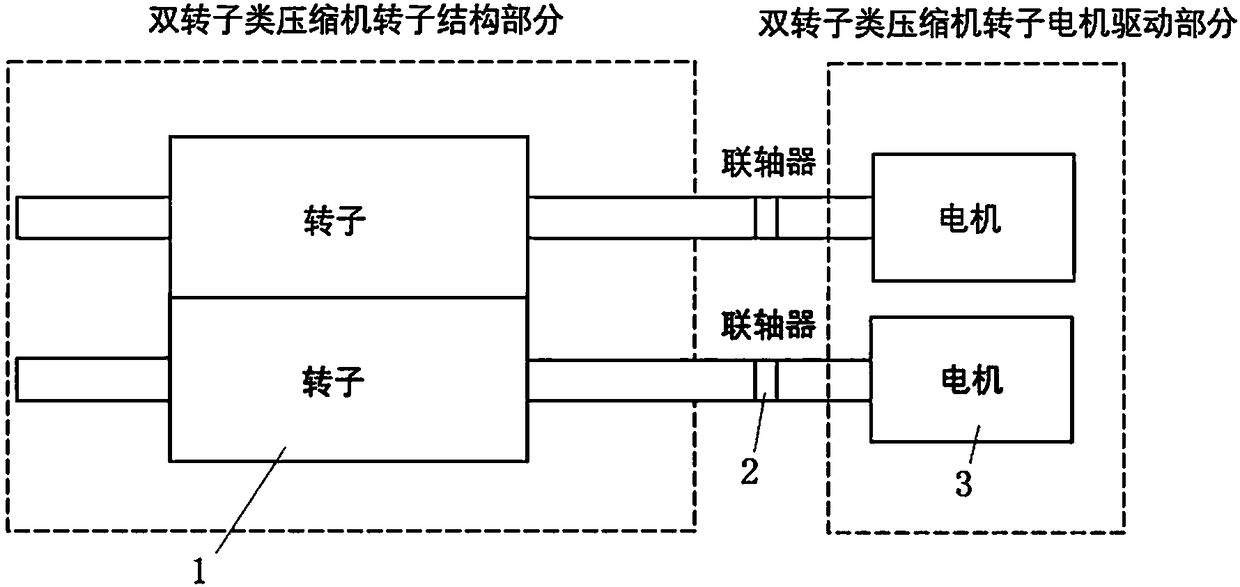

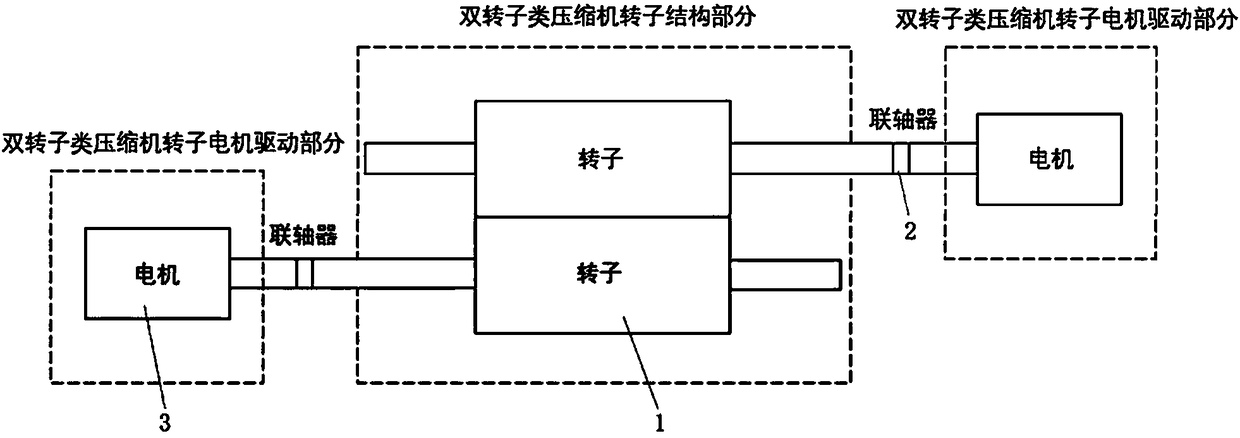

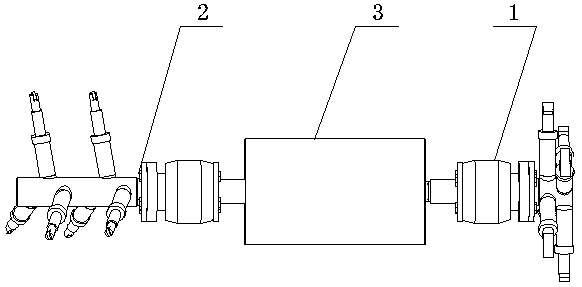

Double-motor driving structure of double-rotor type compressor and control method of double-motor driving structure

PendingCN108361197ALow powerGuaranteed uptimeRotary piston pumpsRotary piston liquid enginesFrequency changerMotor drive

The invention discloses a double-motor driving structure of a double-rotor type compressor and a control method of the double-motor driving structure. The double-motor driving structure comprises twomotors which are correspondingly connected with two compressor rotors through couplers, the two motors are connected with a power supply, and the speed ratio of the two motors is controllable. The control method is divided into three control schemes according to the speed ratio control precision requirement of the compressor rotors, and the control method comprises the two motors directly connected with one power supply, wherein one motor is connected with the power supply through a frequency converter, and the two motors are correspondingly connected with the power supply through the frequency converter; and the frequency converter is provided with a controller, and the controller is used for analyzing the difference value between the speed ratio of two rotation speed sensors and the setspeed ratio; and the set frequency of the frequency converter is adjusted, the rotating speed of the motors connected with the frequency converter is controlled, and the constant speed ratio of the two motors is kept. According to the double-motor driving structure of the double-rotor type compressor and the control method of the double-motor driving structure, the normal operation of the rotor type compressor is ensured, synchronous gears required by a traditional structure is omitted, so that the problem of oil leakage is avoided, and the double-motor driving structure is symmetrical and hasthe effects of reducing noise and the like.

Owner:NINGBO BAOSI ENERGY EQUIP

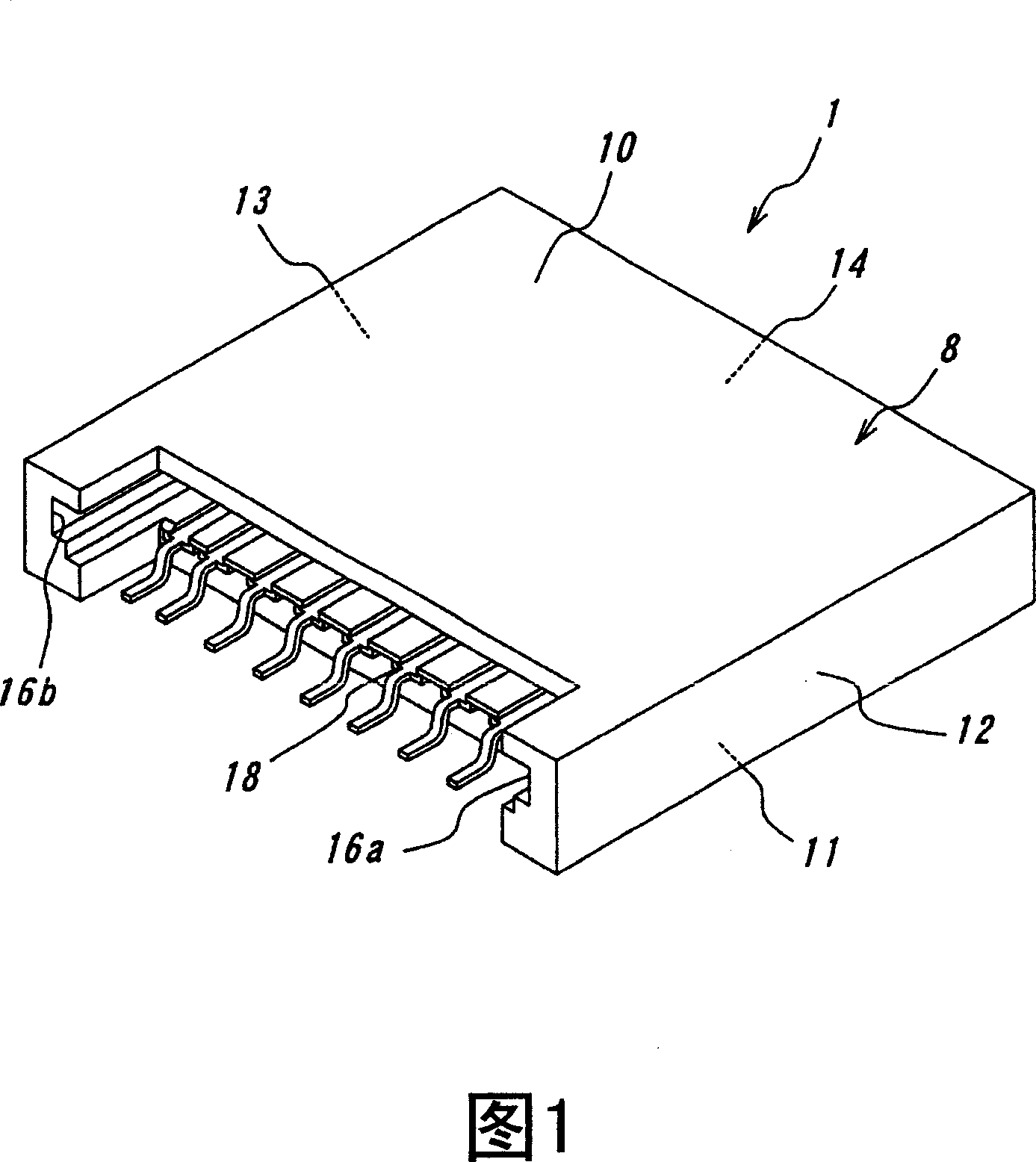

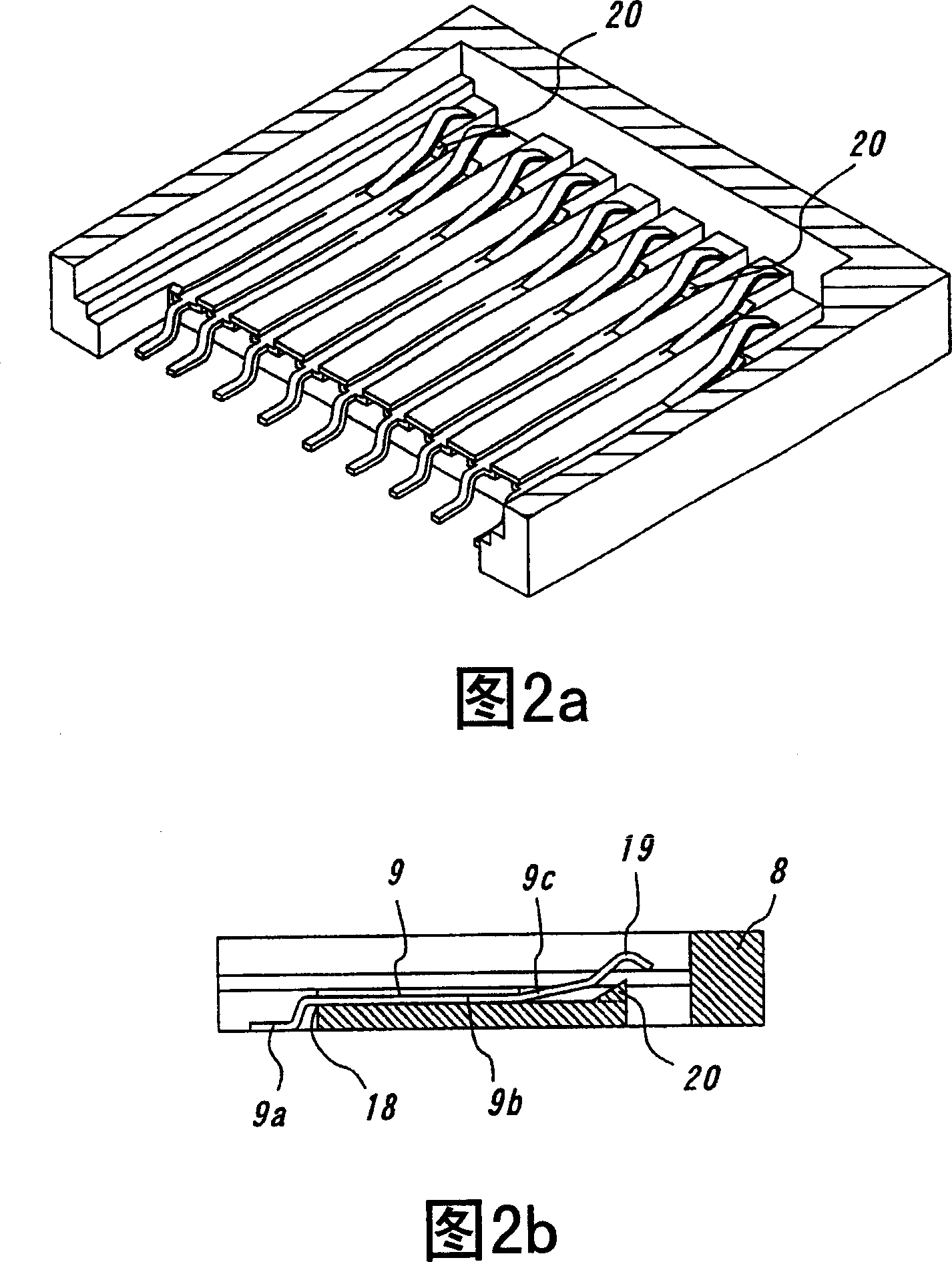

Card connector

InactiveCN100373703CGuaranteed contact forceAvoid plastic deformationOther printing matterElectrically conductive connectionsContact padContact force

A card connector for use with an electronic appliance through an IC card having a plurality of recesses extending from its front end toward its rear end in parallel with one another and contact pads each being received in the recess. The card connector includes a connector housing and contact terminals. The connector housing has a pair of guide grooves for supporting and guiding both side edges of a card being inserted into the card connector and an insertion space in the housing for the inserted card. The contact terminals made of a springy and electrically conductive material are arranged in the connector housing and each have a contact portion adapted to contact with a contact pad of the card normally inserted in the card connector. According to the invention, the card connector comprises support protrusions each provided at a location below at least the contact portion of the contact terminal to limit the downward displacement of the contact portion of the contact terminal when the card has been normally inserted in the card connector, thereby ensuring a contact force more than a predetermined value between the contact portions of the contact terminals and the contact pads of the card.

Owner:DDK LTD

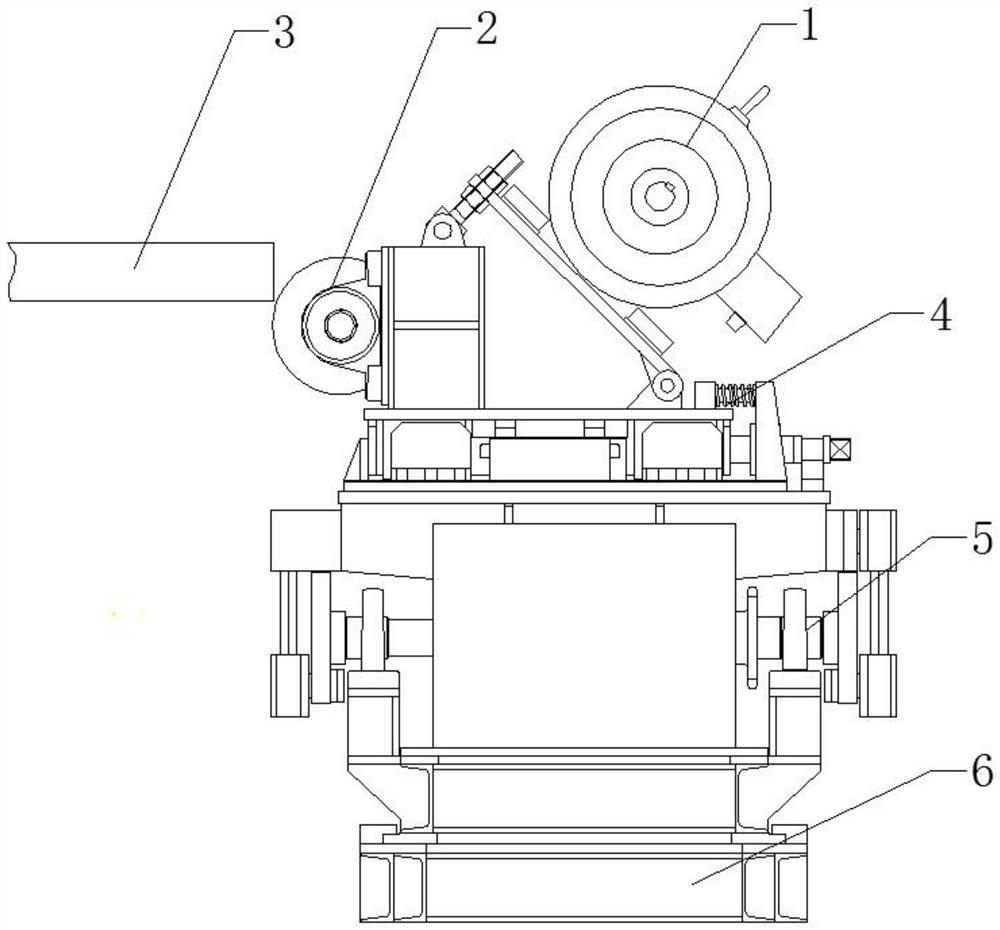

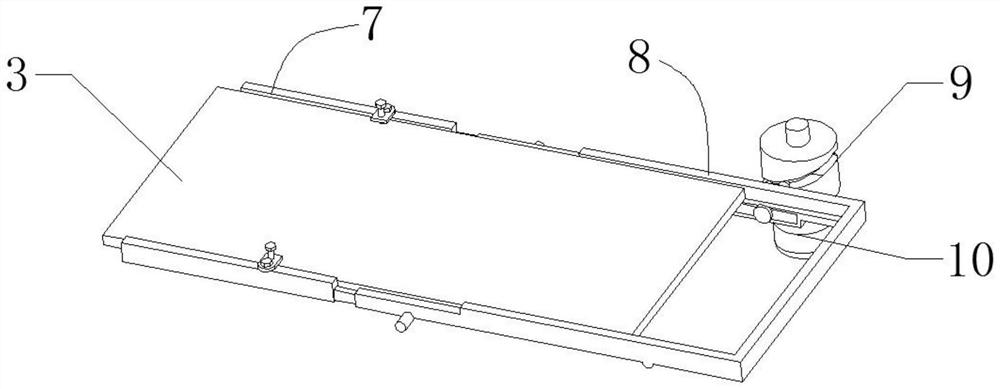

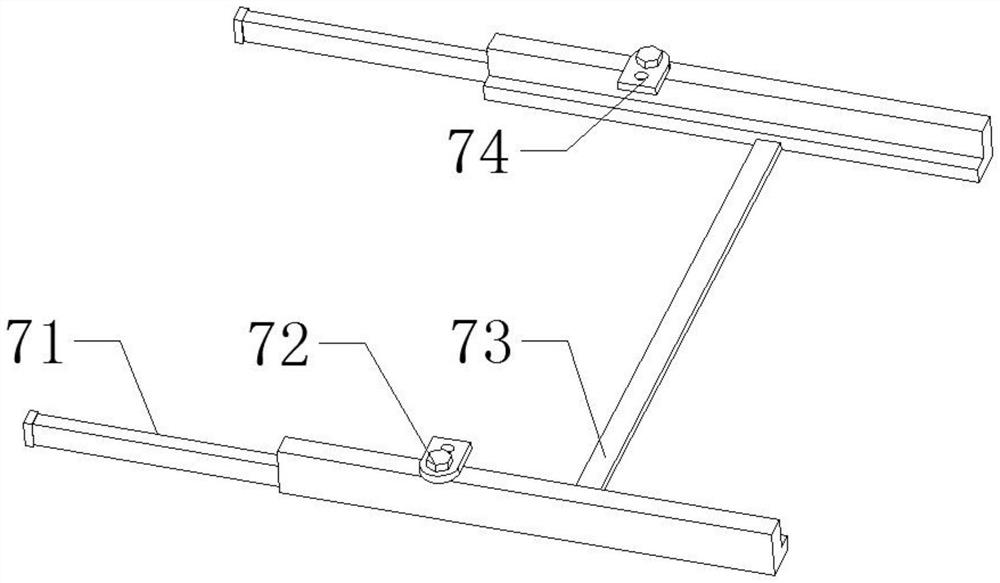

Guardrail plate end corner angle blunting device

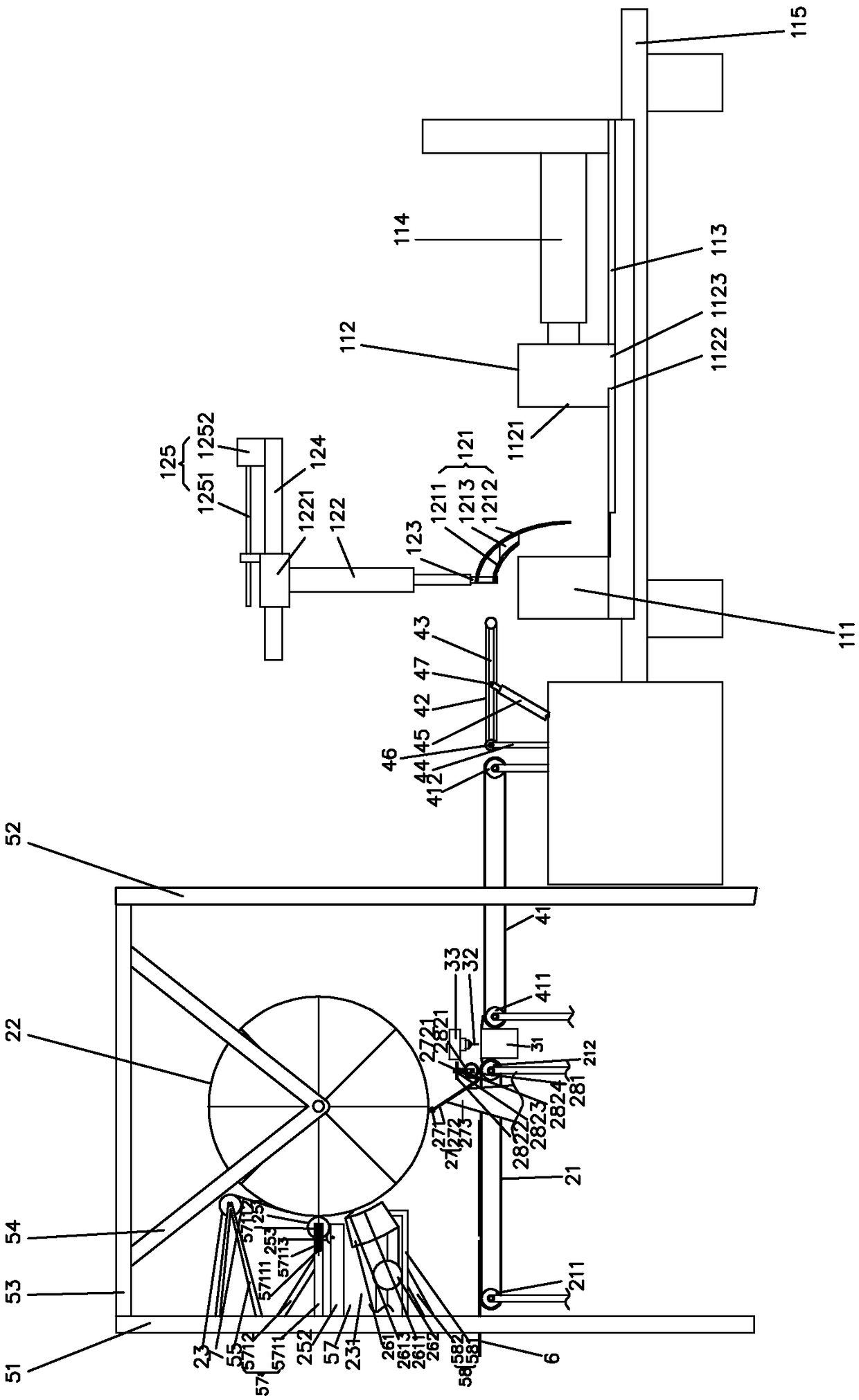

PendingCN114178927AGuaranteed stabilityAvoid sandingEdge grinding machinesGrinding drivesReciprocating motionElectric machinery

The invention is suitable for the technical field of guardrail plate edge and corner grinding equipment, and provides a guardrail plate end edge and corner grinding device which comprises a grinding mechanism and a driving motor, the grinding mechanism comprises a base, a platform arranged at the top of the base, a steel wire roller rotationally connected to the top of the platform and the driving motor for driving the steel wire roller to rotate, and the steel wire roller is rotationally connected to the top of the platform; the driving motor is fixedly connected to the top of the platform. The clamping tool used for clamping the workpiece comprises a first frame and a second frame, a rotating shaft is arranged at the front end of the first frame, the rotating shaft is rotationally connected to a main frame body, a stress rod is arranged at the other end of the first frame, and a space cam for driving the stress rod to reciprocate up and down is arranged on the main frame body. According to the device, the steel wire roller structure is additionally arranged, edge and corner parts of the guardrail plate are blunted, meanwhile, an automatic rotating and clamping tool is additionally arranged, when the guardrail plate is blunted, rotating and edge changing are automatically conducted, automatic blunt grinding of the edge and corner parts of the guardrail plate is achieved, and the labor cost is reduced.

Owner:潍坊东方钢管有限公司

Caliper body, caliper body machining method and method for assembling brake with caliper body

InactiveCN110985568AEasy to clamp and positionSmall contact forceAxially engaging brakesAssembly machinesMachiningDisc brake

The invention relates to the field of pneumatic disc brakes, and discloses a caliper body, a caliper body machining method and an assembly method of a brake with the caliper body. The caliper body isof an integrally-formed structure. A first assembly cavity is formed in the caliper body; a supporting frame is formed on the lower side of the first assembling cavity, pin holes are formed in the left side and the right side of the supporting frame, a shaft hole and a pressing hole are formed in the upper end face of the first assembling cavity, a stress part is formed in the first assembling cavity, a matching notch used for being matched with a rolling shaft is formed in the lower end face of the stress part, and the axis of the matching notch is perpendicular to that of the shaft hole; a process hole is formed in the side face of the first assembling cavity, and the projection of the matching notch in the extending direction of the matching notch falls into a projection area of the process hole in the axis direction of the matching notch. The brake has the advantages of being reliable in braking, easy to machine and high in production efficiency. Moreover, the caliper body is simple to process, and other parts are convenient to assemble.

Owner:ZHEJIANG VIE SCI & TECH

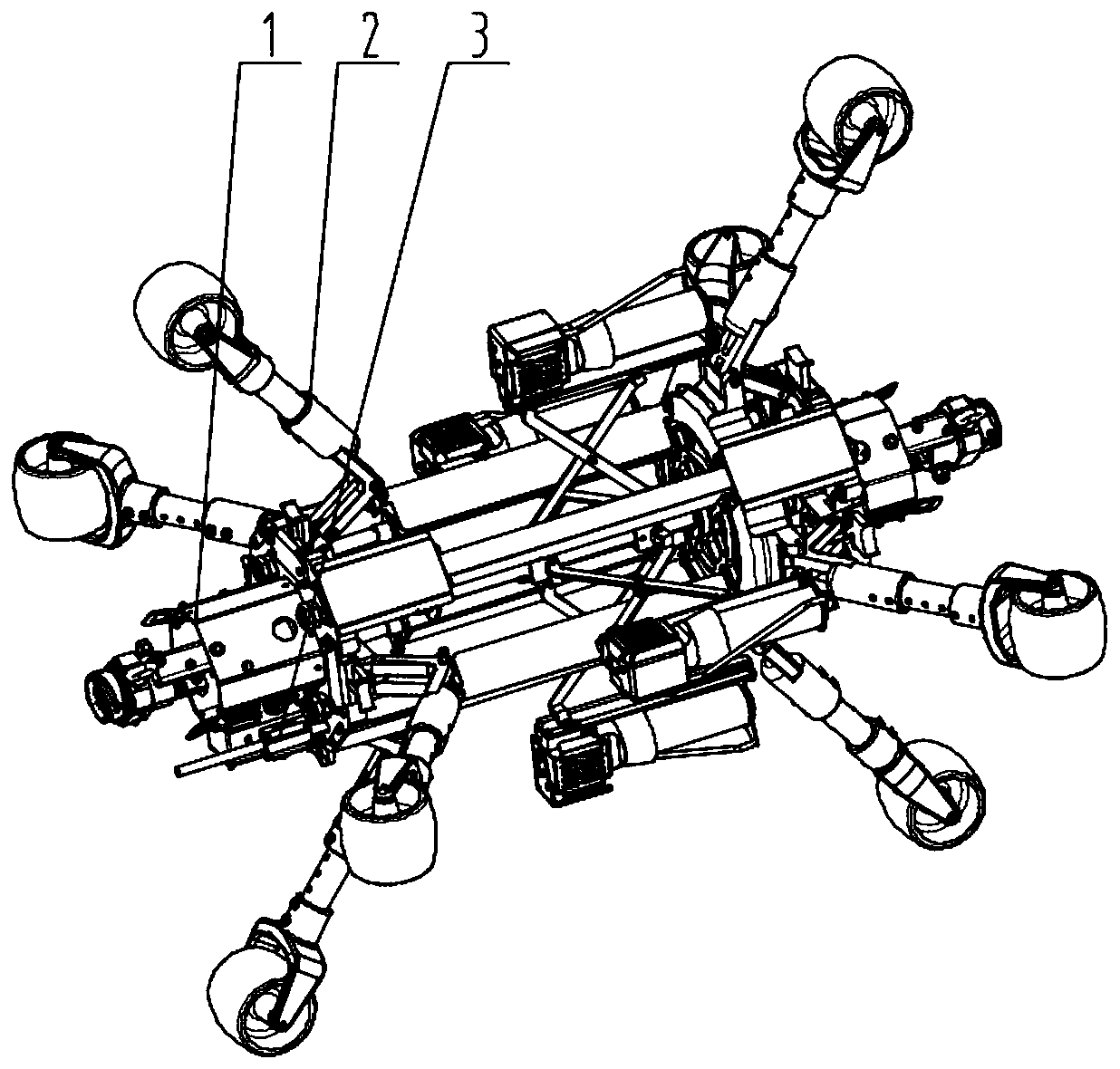

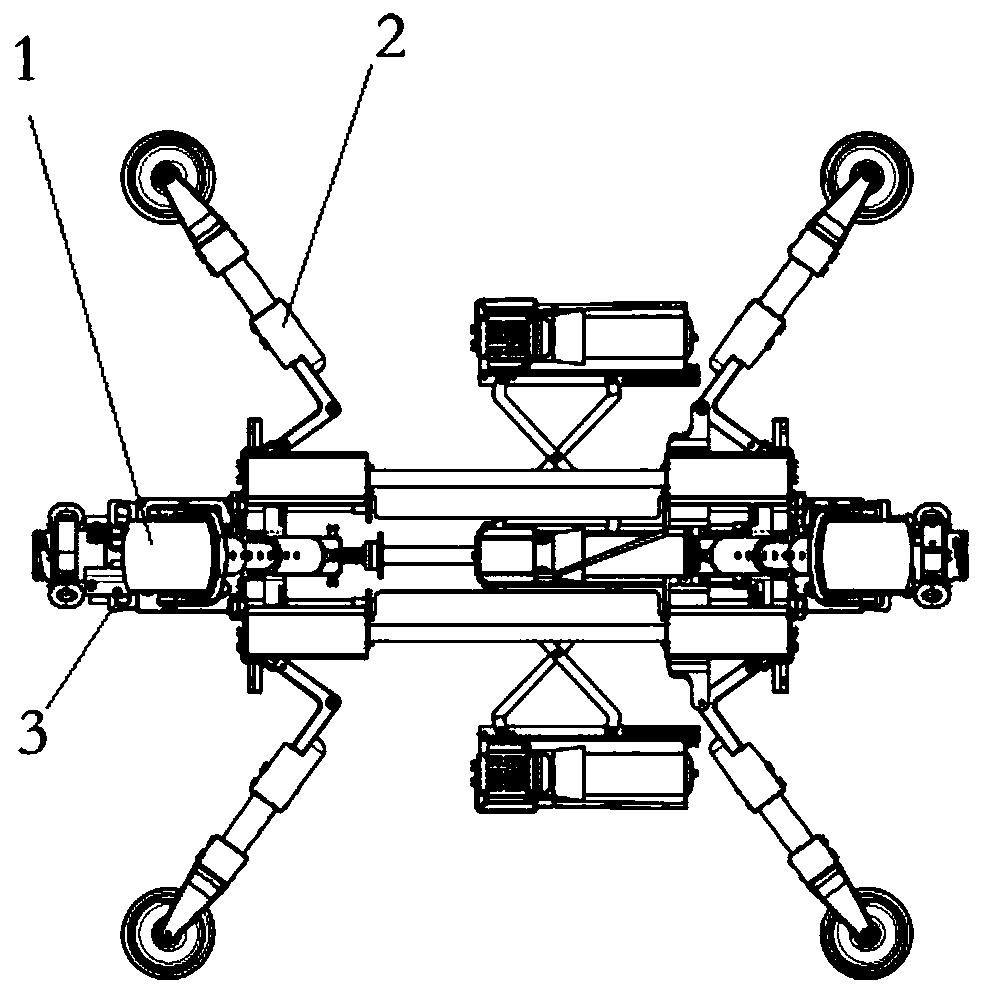

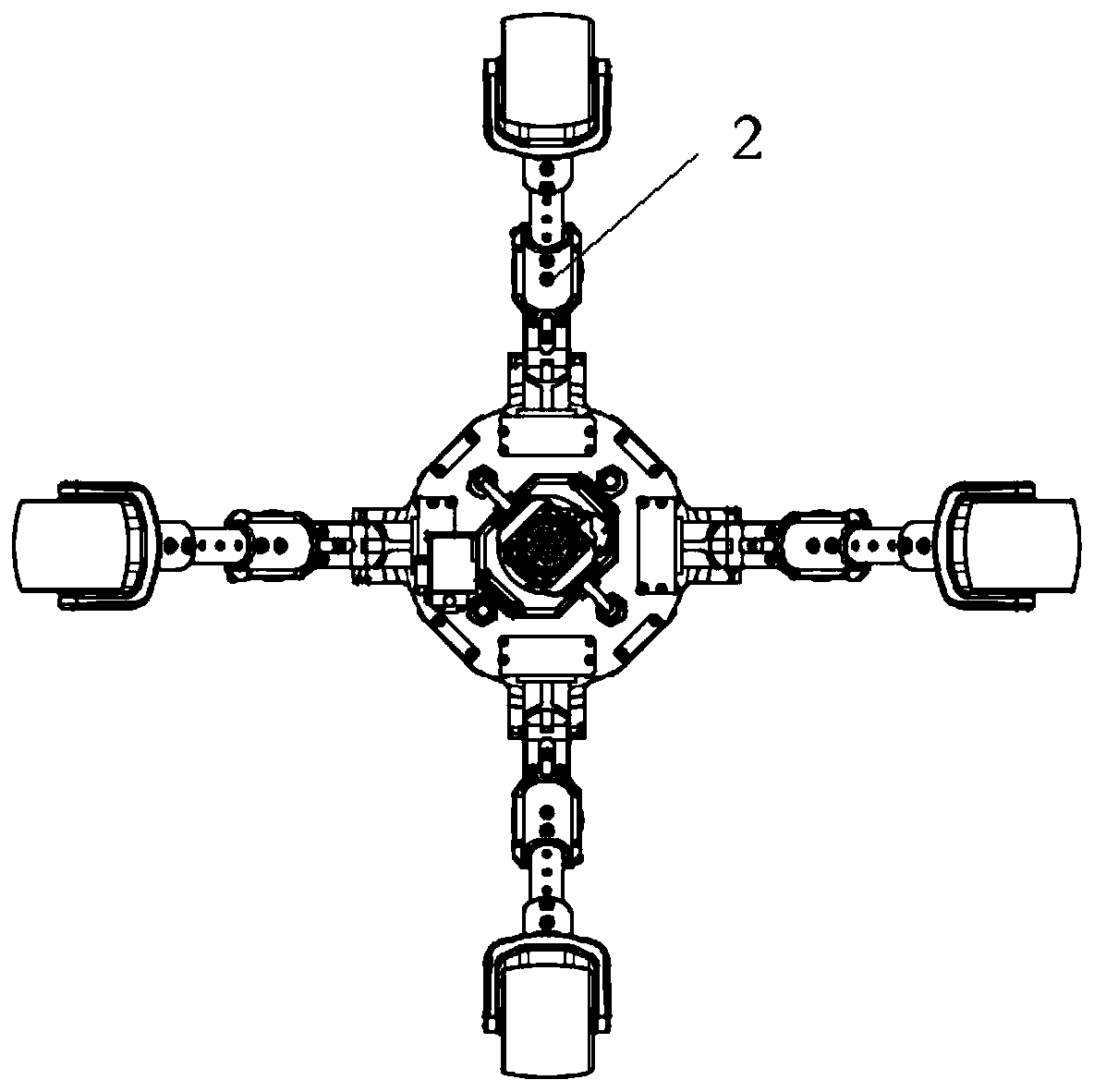

Spiral push type pipeline cleaner

ActiveCN108672422ASimple structureImprove practicalityHollow article cleaningDrive shaftContact force

The invention relates to a pipeline cleaner, in particular to a cleaner for a spiral push type pipeline cleaner to a petroleum pipeline. The cleaner comprises a washing device, a pushing device and apower device; a cover plate is arranged at one end of a shell of the power device, and a blocking plate is arranged at the other end of the cover plate; transmission holes are formed in the center ofthe cover plate and the center of the blocking plate respectively; and a transmission shaft A is arranged in the transmission hole of the cover plate, a pushing device is arranged on the transmissionshaft A, a transmission shaft B is arranged in a transmission hole of the blocking plate, and a washing device is arranged on the transmission shaft B. The cleaner can work in a variable-diameter pipeline through telescoping of a telescopic arm, the contact force between a roller or a brush cutter and the pipe wall in the working process is kept, the problem that because an existing pipeline cleaner is complex in structure and low in cleaning efficiency, and cannot work in the variable-diameter pipeline, the cleaning effect is influenced to a certain degree is solved, and the spiral push typepipeline cleaner is particularly suitable for being used for removing water scale or oil dirt.

Owner:YANGTZE UNIVERSITY

Novel lock nut

ActiveCN104454903AGuaranteed anti-loose performanceAvoid wear and tearNutsBoltsEngineeringScrew thread

Owner:缙云县科智达机械有限公司

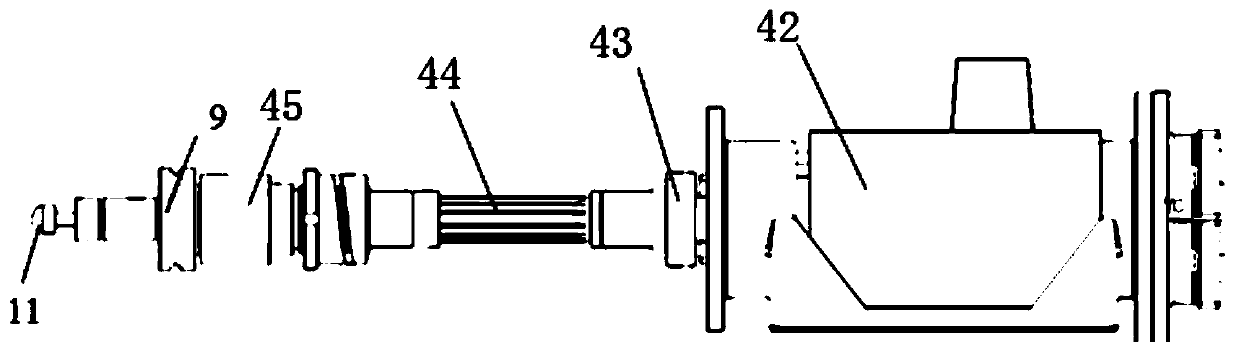

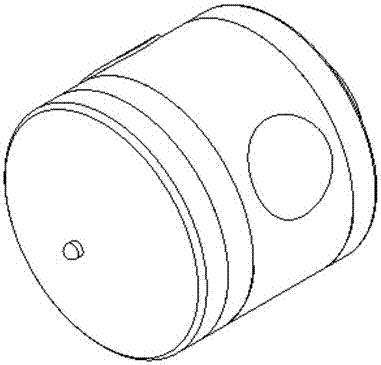

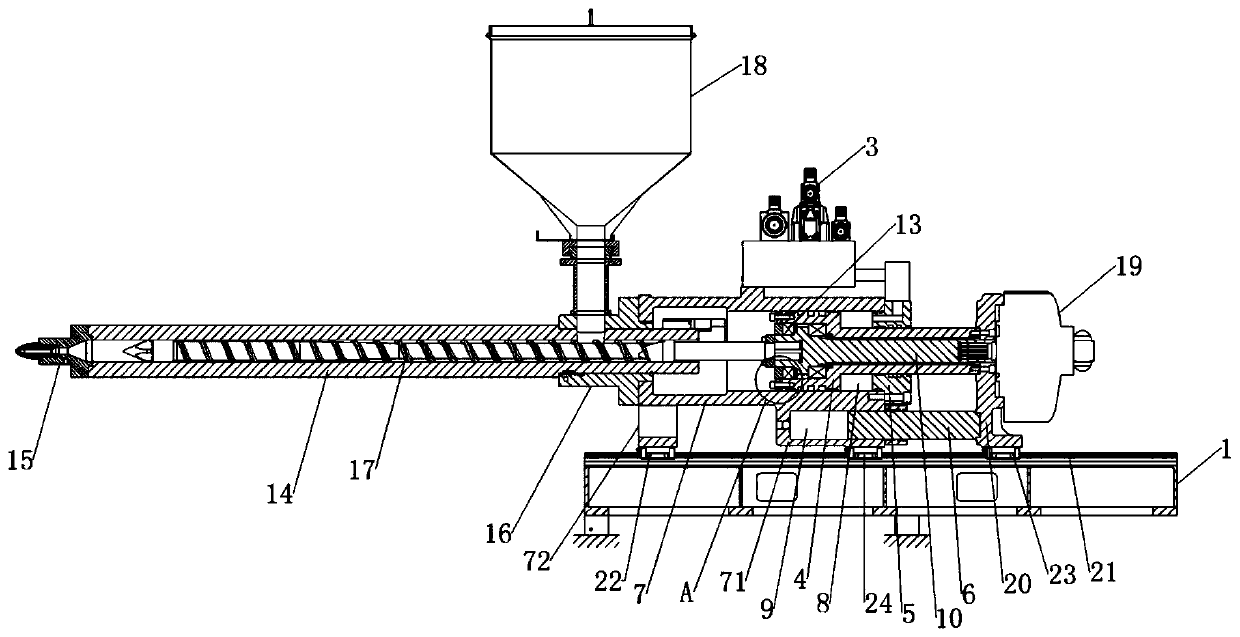

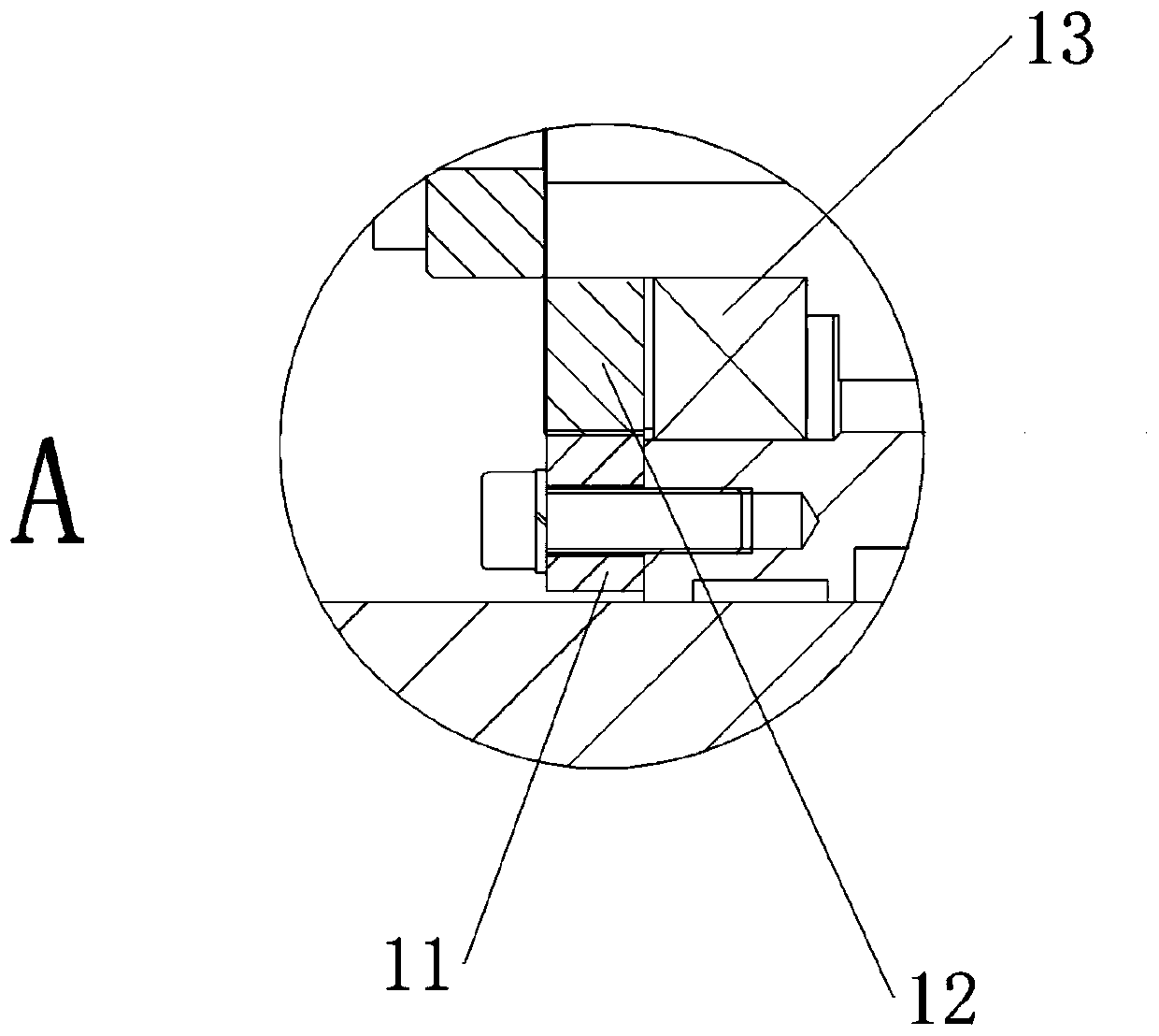

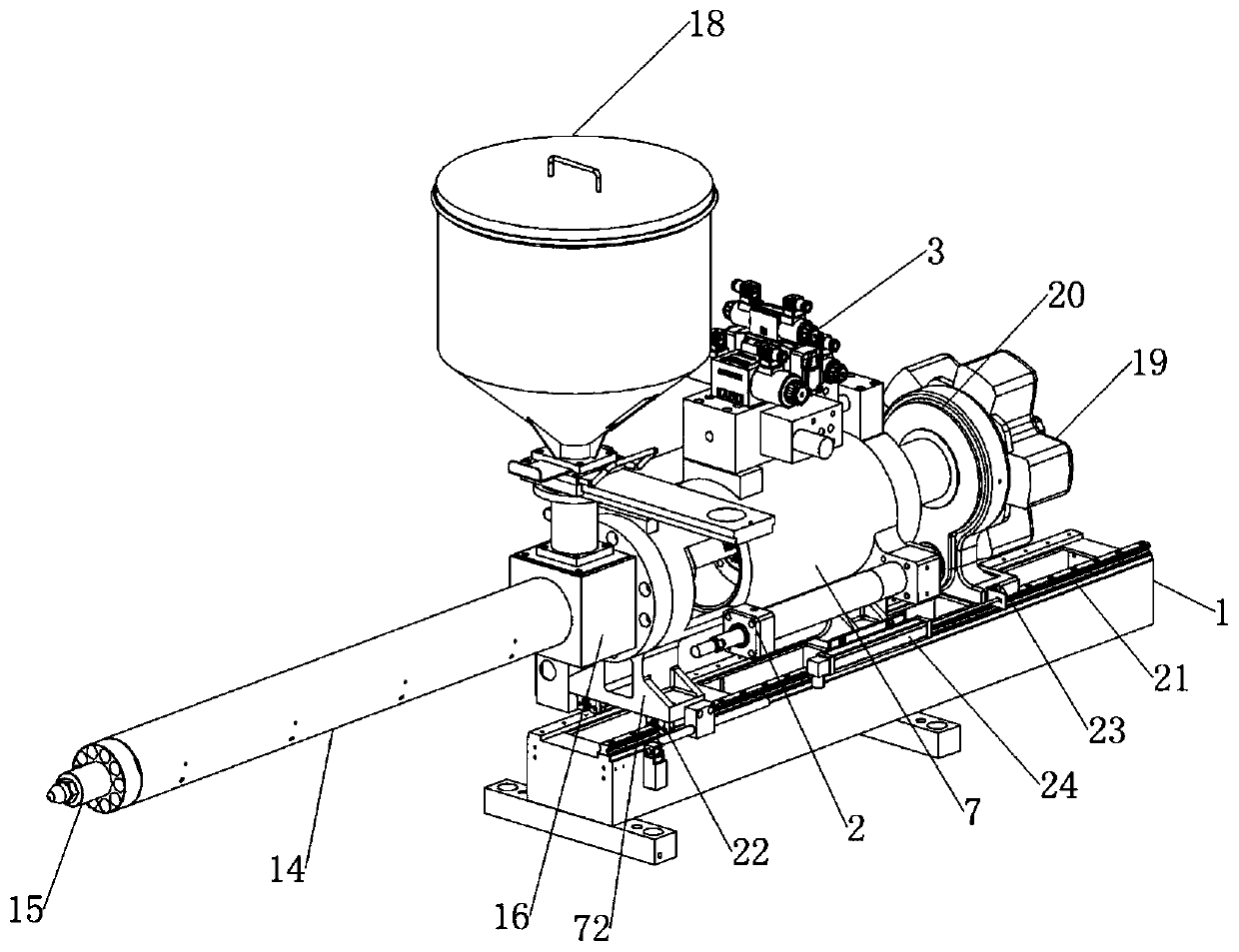

Single-cylinder type injection device

The invention discloses a single-cylinder injection device. The device comprises a support, an oil circuit integrated package, an injection piston, an injection rear end cover, an injection retreat plunger, an injection seat, a transmission shaft, a motor and a motor seat, wherein the injection seat and the motor seat are both arranged on the support, the motor is arranged on the motor seat, the motor is connected with the transmission shaft, the injection piston is arranged on the transmission shaft in a sleeving mode and is fixedly connected with the motor seat, the injection seat and the injection rear end cover are both arranged on the injection piston in a sleeving mode, the injection rear end cover is fixedly connected with the injection seat, the injection seat is provided with an extension section, an injection retreat oil cavity is formed in the extension section, one end of the injection retreat plunger is arranged in the injection retreat oil cavity, the other end of the injection retreat plunger is fixedly connected with the motor seat, the injection piston is positioned right above the injection retreat plunger, an injection oil cavity is defined by the injection piston, the injection rear end cover and the injection seat, and the injection oil cavity and the injection retreat oil cavity communicate with the oil circuit integrated package.

Owner:GUANGDONG BLOOMACHINE

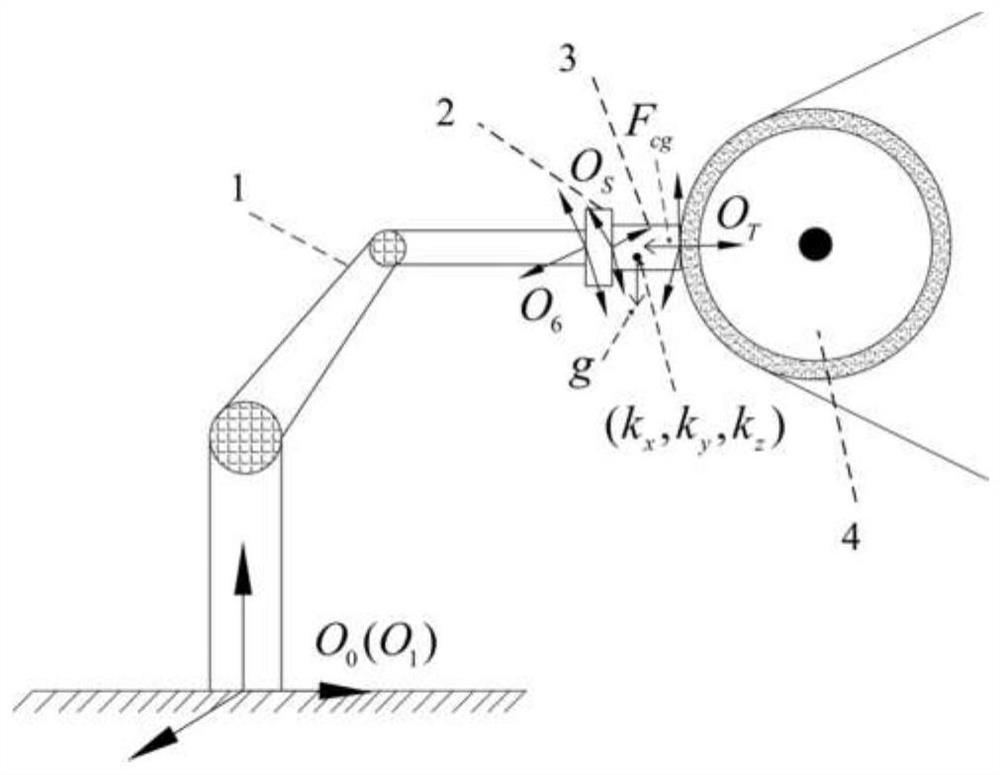

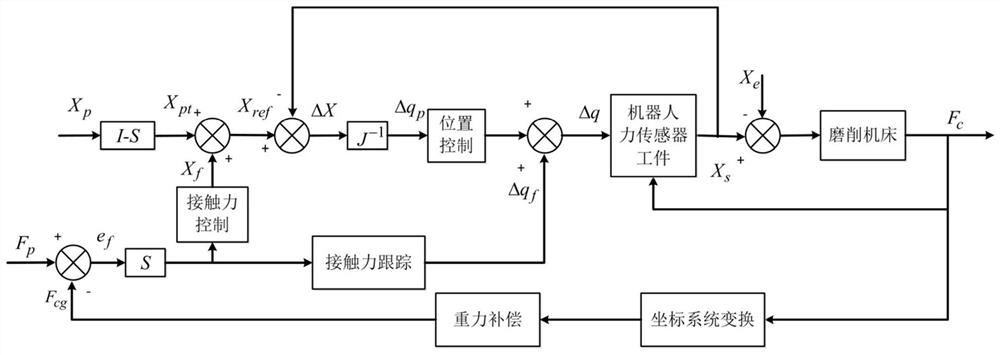

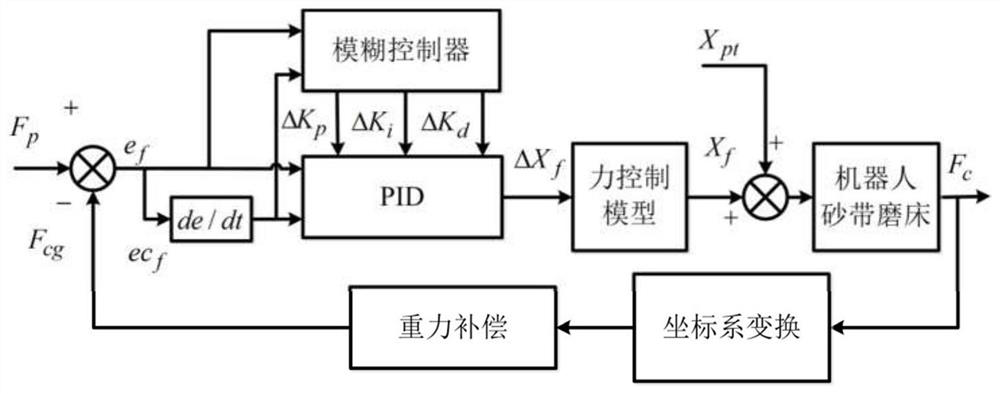

Intelligent control method in automatic grinding operation process of robot

ActiveCN114310571AImplement load gravity solutionGuaranteed contact forceAutomatic grinding controlGrinding machinesSanderFuzzy pid control

The invention relates to an intelligent control method for an automatic grinding operation process of a robot. A force sensor is fixed at the tail end of a robot, a workpiece is clamped at the tail end of the sensor, the workpiece is ground on a belt sander through position control of the robot, and the force sensor is used for detecting contact force and torque between the workpiece and the belt sander. And the upper computer, the sensor and the robot carry out transmission by using an IP / UDP protocol to realize control. According to the grinding operation, high-precision contact force control is achieved through force-position hybrid control, a gravity compensation algorithm and contact force solving are achieved, and constant force control is achieved based on fuzzy PID control. In order to effectively avoid the over-grinding phenomenon of the initial position and the end point of a grinding path and the position where the surface of a workpiece fluctuates greatly, torque control is added into a control strategy to achieve force and torque fusion control. According to the intelligent control strategy, quantitative removal of materials for workpiece grinding operation can be achieved, and in addition, the method is high in universality and suitable for grinding machining of various complex curved surface parts.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

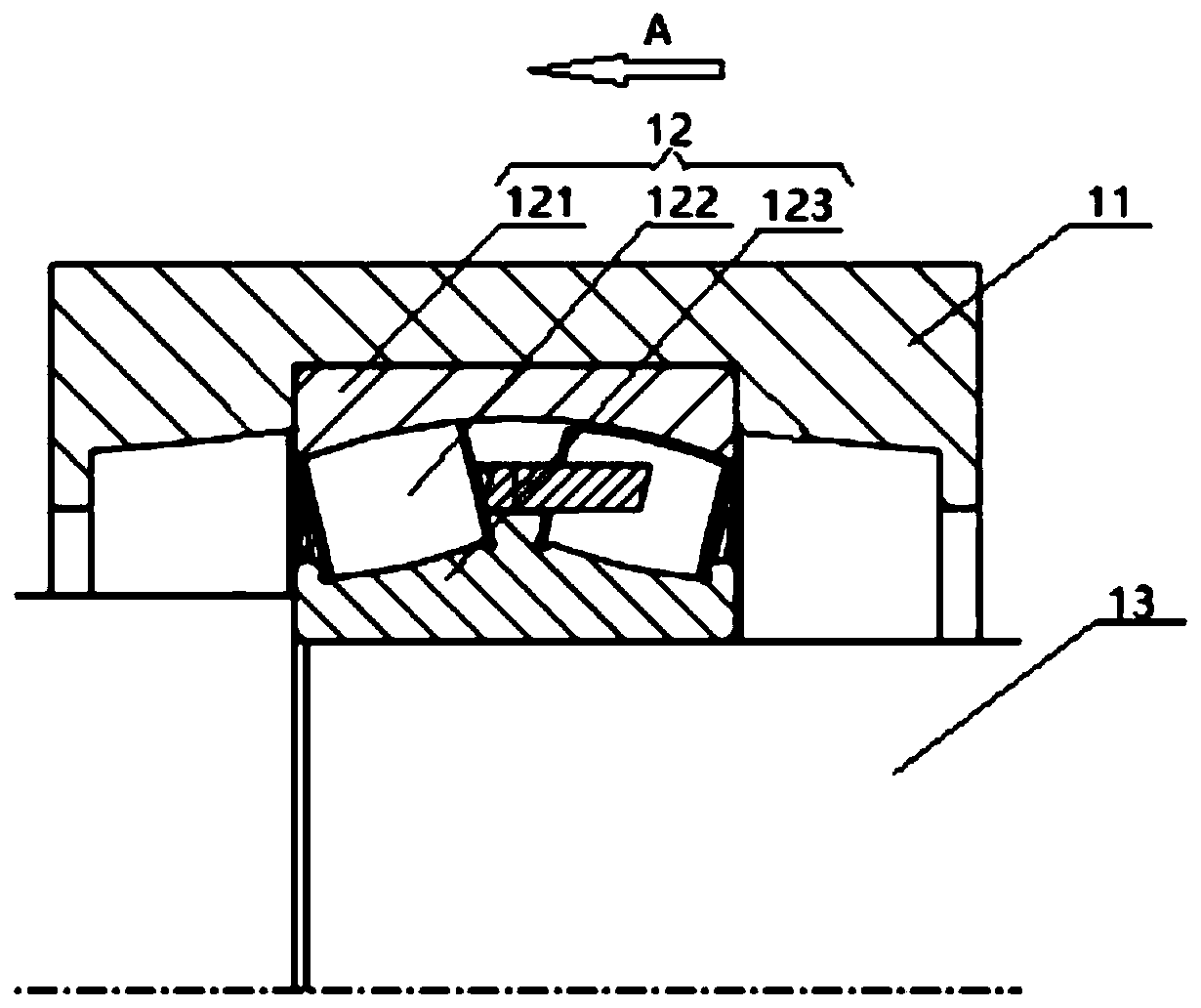

Bearing assembly and roller bearing thereof

InactiveCN110030259AEliminate axial playReduce axial playRoller bearingsBearing componentsFixed bearingAxial force

Embodiments of the invention provide a bearing assembly and a roller bearing thereof. The roller bearing comprises a fixed bearing ring comprises a first fixed bearing ring portion and a second fixedbearing ring portion which are arranged coaxially, and a rotating bearing ring coaxially arranged with the fixed bearing ring, wherein the first fixed bearing ring portion and the second fixed bearingring portion are same in radial dimension; an axial gap is formed between the first fixed bearing ring portion and the second fixed bearing ring portion; the axial gap is greater than or equal to half of the axial backlash of the roller bearing; and the rotating bearing ring is mounted inside or outside the fixed bearing ring in a sleeved or sleeving mode. According to the bearing assembly and the roller bearing thereof which are provided by the embodiments of the invention, the influence on the service life of the bearing under the action of axial force can be reduced.

Owner:SCHAEFFLER TECH AG & CO KG

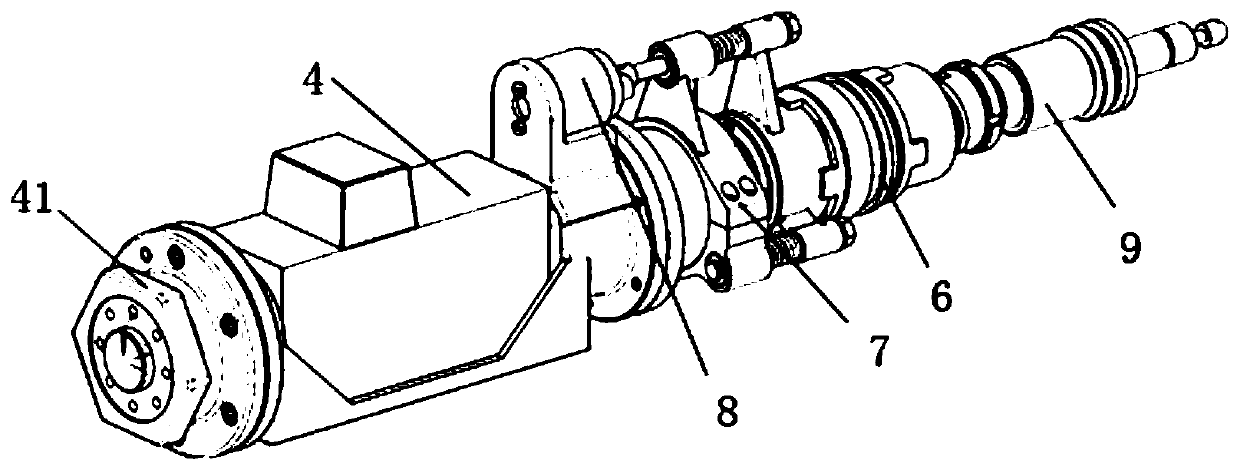

Servo drive type floating mechanism

A servo drive type floating mechanism comprises a holding seat, a grinding tool, a posture sensor, a displacement sensor, an inner frame and a first servo motor. The grinding tool is clamped in the holding seat, and the grinding tool is provided with a first pivot and a grinding tool body. The first pivot is perpendicular to the axis direction of the grinding tool. The posture sensor is used for sensing the posture of the grinding tool and sending out a posture signal, and the posture signal is calculated to obtain a torque compensation value aiming at the influence of gravity. The displacement sensor is used for sensing the displacement amount of the grinding tool along the first pivot. The grinding tool is arranged in the inner frame, and a first pivot of the grinding tool is movably arranged in the inner frame. The first servo motor is arranged in the inner frame and drives the grinding tool to rotate along the first pivot according to the torque compensation value and the displacement, so that torsion output by the grinding tool is not affected by gravity in various postures.

Owner:许又升

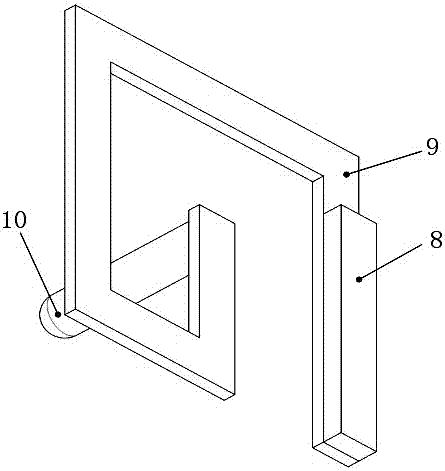

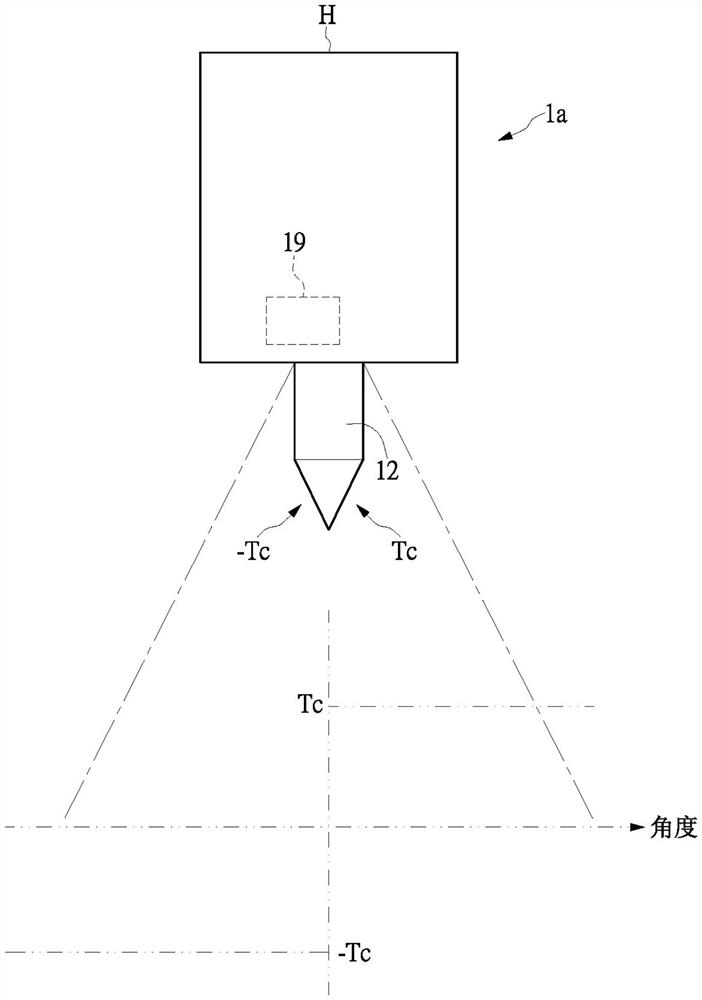

A stepless gear position adjustment system and method suitable for outrigger mechanism

The invention provides a stepless gear adjusting type position adjusting system and method suitable for a landing leg mechanism. The system comprises a lamp bracket framework body, the landing leg mechanism, a position adjusting and limiting device, a landing leg drive motor and an electric control system, the landing leg drive motor is started to rotate forwards or reversely, a landing leg is expanded or contracted, and after the expanded angle of the landing leg reaches the maximum angle limited by the position adjusting and limiting device, the adjusting and limiting device sends stop signals to the electric control system. After the contraction angle of the landing leg reaches the minimum angle limited by the position adjusting and limiting device, the adjusting and limiting device sends stop signals to the electric control system, and after the electric control system receives the stop signals, the landing leg drive motor is controlled to stop rotating. The position adjusting andlimiting device is exquisite in structure, the position adjusting manner is simple and fast, huge mechanical structures and complex data algorithms are avoided, the adjusting process of the position adjusting and limiting device is stable, efficient and accurate, the position of an ultraviolet lamp and contact force exerted on the pipe wall from the landing leg are guaranteed through accurate control over the expanding angle through the position adjusting and limiting device, and the final repairing effect is guaranteed.

Owner:安徽普洛兰管道修复技术有限公司

Novel automatic lock bolt

ActiveCN104482022AAvoid wear and damageGuaranteed anti-loose performanceNutsBoltsEngineeringMechanical engineering

The invention discloses a novel automatic lock bolt. An accommodating slot is formed in a screw rod; the accommodating slot is communicated with a horizontal through slot; a first cylinder is arranged at the bottom of the accommodating slot; the first cylinder is provided with a stretching rod which upward extends out; a pushing block is arranged on an end part of the stretching rod of the first cylinder; a switch is arranged on an upper surface of a bolt head; I-shaped parts of two L-shaped rotating blocks are abutted to each other and are accommodated in the accommodating slot; a gap is remained between a lower end part of a bulge and the bottom of the horizontal through slot; the I-shaped parts of two L-shaped rotating blocks can slide up and down in the accommodating slot; when the I-shaped parts of two L-shaped rotating blocks upward slide to the top positions, the I-shaped parts can be downward turned; a '-' part of each L-shaped rotating block comprises a fixing block, a connecting block and a second cylinder; a second switch is arranged on the upper surface of the bolt head. The novel automatic lock bolt provided by the invention can avoid the abrasion or damage to the bulge; the stretching forces of the cylindesr can ensure the contact force and frictional force between the bulge and the two lateral surfaces; the occupied space is small; the novel automatic lock bolt is conveniently taken and used.

Owner:苏州博锦自控阀业有限公司

An automatic new lock nut

ActiveCN104454902BGuaranteed anti-loose performanceAvoid wear and tearNutsBoltsAgricultural engineeringEngineering

Owner:SUZHOU ZHONGTUO PATENT OPERATION MANAGEMENT CO LTD

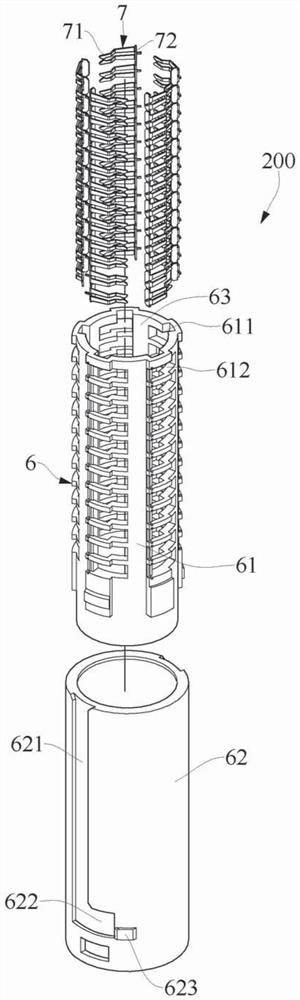

High Density Contact Connection Device

ActiveCN110034440BHigh densityImprove reliabilityCoupling contact membersCouplings bases/casesHigh densityMechanical engineering

The invention provides a high-density contact point connecting device, and the device comprises a plug connector and a socket connector, wherein the plug connector comprises a first insulating body and a plurality of first terminals, the first insulating body is provided with a column body part, and the plurality of first terminals are arranged on the column body part. The socket connector comprises a second insulating body and a plurality of second terminals, wherein the second insulating body is provided with a cylinder part, an accommodating space is formed in the cylinder part, and the plurality of second terminals are arranged on the cylinder part. The column body part of the plug connector can be inserted into the accommodating space of the socket connector, and the plug connector and the socket connector can rotate relatively, so that the first contact parts of the first terminals are clamped between the two second contact parts of the second terminals, and the plurality of first terminals and the plurality of second terminals are in contact conduction. Therefore, high-density and high-reliability signal contact points can be generated.

Owner:ZHENGLING PRECISION IND GUANGDONG +1

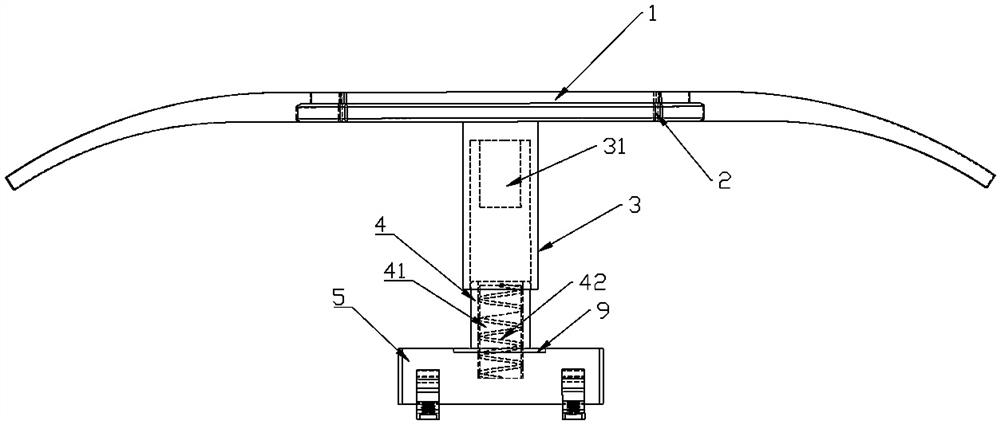

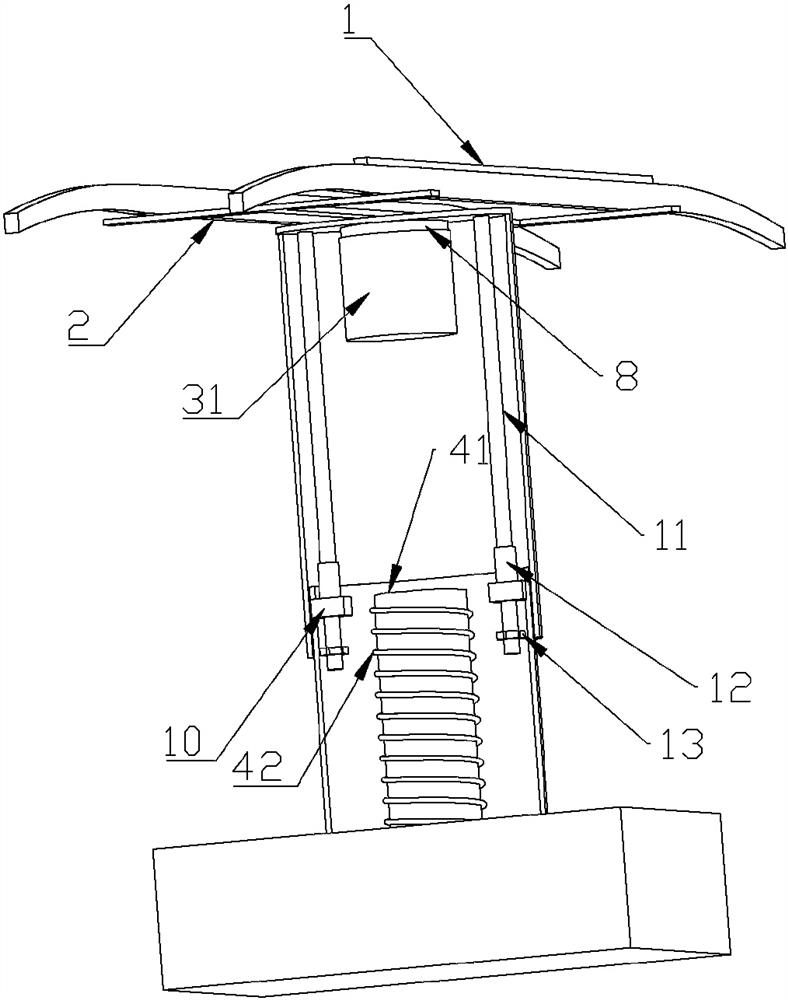

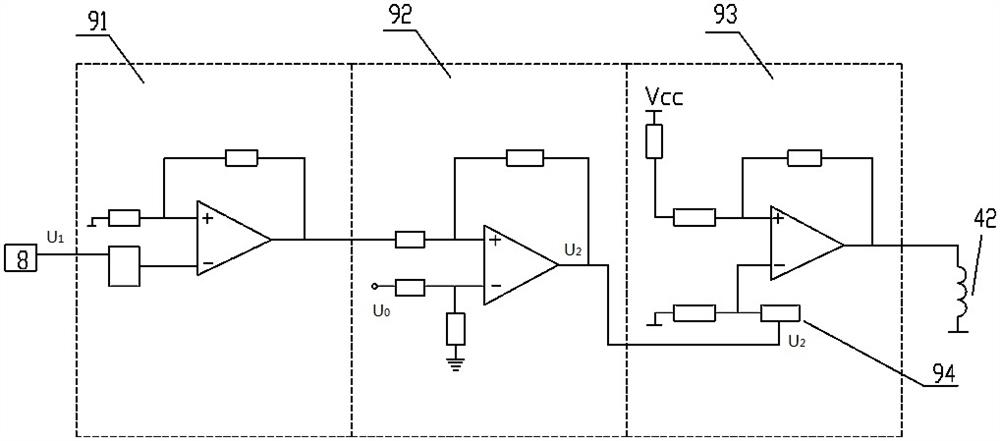

A magnetic repulsion suspension pantograph

ActiveCN114435139BAdjust the size of the current in real timeAdjustable sizePower current collectorsContact pressureExcitation current

The invention relates to the technical field of electrified railway locomotives, and discloses a magnetic repulsion type suspension pantograph, which includes a base, a bow head bracket and a carbon slide plate, the carbon slide plate is arranged on the bow head bracket, and the base is installed to drive the bow head bracket to rise and fall The electromagnetic mechanism includes an inner cylinder, an outer cylinder, a permanent magnet and an iron core. The carbon slide plate is set on the outer top of the outer cylinder, the inner cylinder is fixed on the base, the permanent magnet is set on the outer cylinder, the iron core is set on the inner cylinder, and the iron A solenoid is wound on the core, a control circuit board for controlling the excitation current in the solenoid is arranged on the base, and a pressure sensor is arranged inside the outer cylinder. The beneficial effects of the present invention are: the pressure sensor is used to monitor the pantograph-catenary contact pressure in real time, and feeds back to the control circuit board, and the control circuit board adjusts the excitation current according to the pressure value and the built-in control algorithm to ensure that the pantograph-catenary contact force is stable at the setting value, so as to ensure the pantograph-catenary flow quality.

Owner:SOUTHWEST JIAOTONG UNIV

In-head cold press

ActiveCN109015952AReduce liquidityAvoid large areas of sheddingOther plywood/veneer working apparatusWood veneer joiningBrush deviceUltimate tensile strength

The invention provides an in-head cold press. A structure form of a traditional plywood cold press is broken through, in the actual working process, under the control of a main controller, a glue brushing device brushes glue on a template blank, then a continuous glue-brushing template is cut into glue-brushing template blocks by a cutting device, and the glue-brushing template blocks are conveyedto a cold-pressing executing device by a conveying device to be subjected to cold-pressing forming. A glue fixing net cloth layer can further serve as a reinforcing rib of a finished plywood productwhile it is ensured that the glue fixing net cloth layer and the template blank can be bonded together through glue penetration, and thus a plywood is more elastic and is not prone to deforming and fracture damage. Compared with the prior art, the in-head cold press can conduct continuous and smooth glue brushing and cold-pressing forming on the template bank, the mechanization degree is high, andthe finished plywood product is higher in strength.

Owner:漳州鑫华成机械制造有限公司

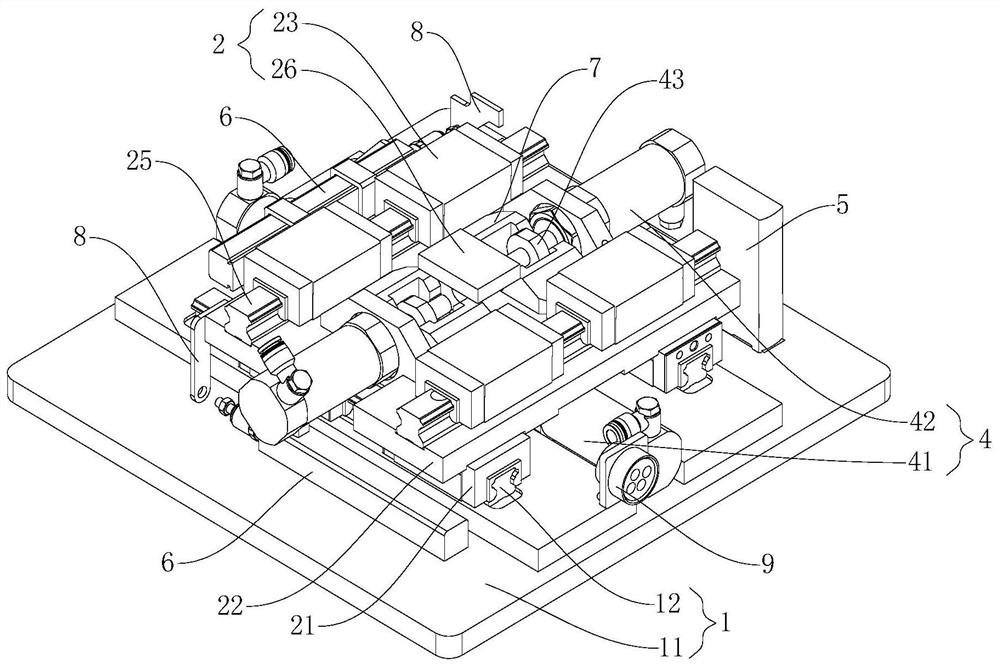

Self-protected two-degree-of-freedom constant force platform

ActiveCN111745537BPlay a protective effectAvoid destructionGrinding carriagesGrinding drivesConstant forceEngineering

The present invention relates to the technical field of constant force grinding, and proposes a self-protecting double-degree-of-freedom constant force platform, which includes a moving mechanism that moves on a base, and the moving mechanism has a moving end; a mounting plate is arranged on the moving end; the constant force mechanism has a second One constant force cylinder, the second constant force cylinder and clamps, the push shafts of the first constant force cylinder and the second constant force cylinder are provided with clamps, the push tops of the first constant force cylinder and the second constant force cylinder The moving mechanism is contacted; the block is provided with a card slot, and the card part is placed in the card slot; the control valve is arranged on the air supply pipeline of the constant force mechanism. Through the above technical solution, the problem in the prior art that the grinding pressure on the workpiece is not constant is solved.

Owner:秦皇岛汇久科技有限公司

Scraper strip and cleaning device

PendingCN114847822AGuaranteed cleanlinessAvoid deformationCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention generally relates to the technical field of cleaning, in particular to a scraping strip and a cleaning device.The cleaning device is provided with the scraping strip, the scraping strip is provided with a scraping strip body, a limiting part, an elastic part and a connecting part, the scraping strip body is used for being slidably connected with the cleaning device, and when the pressure borne by the scraping strip is increased or the height of a cleaning face is increased in the cleaning process, the scraping strip body is connected with the limiting part. The position of the scraping strip body can be adjusted in a sliding mode according to pressure, large deformation is avoided, the angle of the scraping strip body relative to a cleaning face is guaranteed, the cleaning effect of the scraping strip is guaranteed, the elastic part is connected with the scraping strip body, the connecting part is connected with the elastic part, and the connecting part is used for being connected with a cleaning device. The elastic part is bent and applies internal stress to the scraping strip main body, so that the scraping strip main body extrudes the cleaning surface; when the height of the cleaning face is reduced, the elastic part can drive the scraping strip body to move towards the cleaning face, the position of the scraping strip body is adjusted, the contact force between the scraping strip body and the cleaning face is guaranteed, and the cleaning effect is guaranteed.

Owner:深圳市智绘科技有限公司

A locking bolt

ActiveCN104454915BGuaranteed anti-loose performanceAvoid wear and tearNutsBoltsContact forceEngineering

Owner:辽宁实强机械制造有限公司

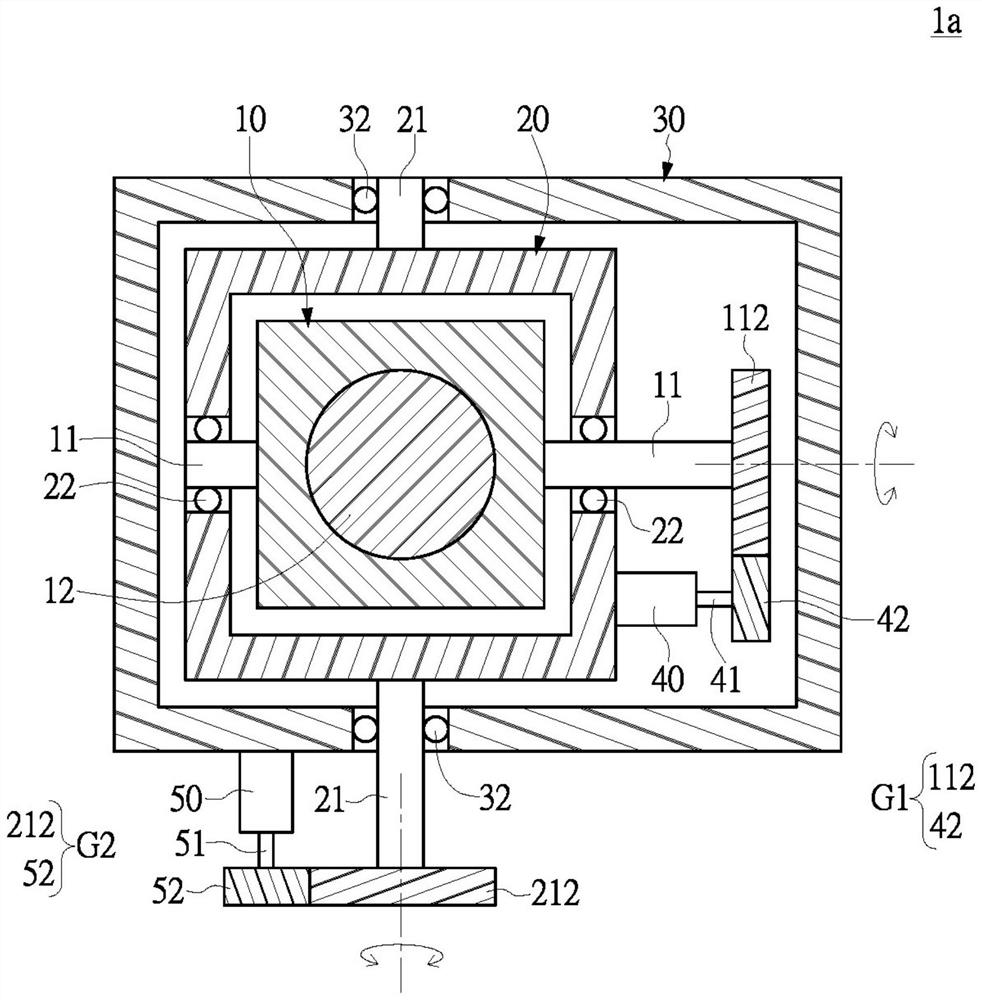

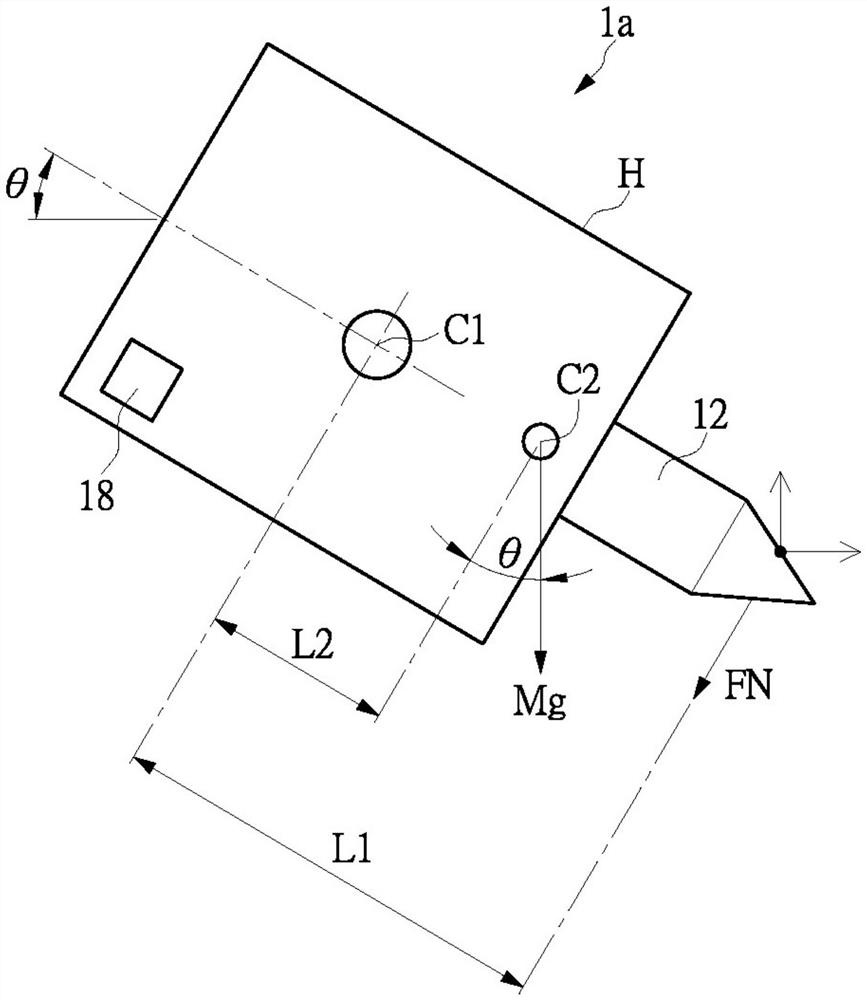

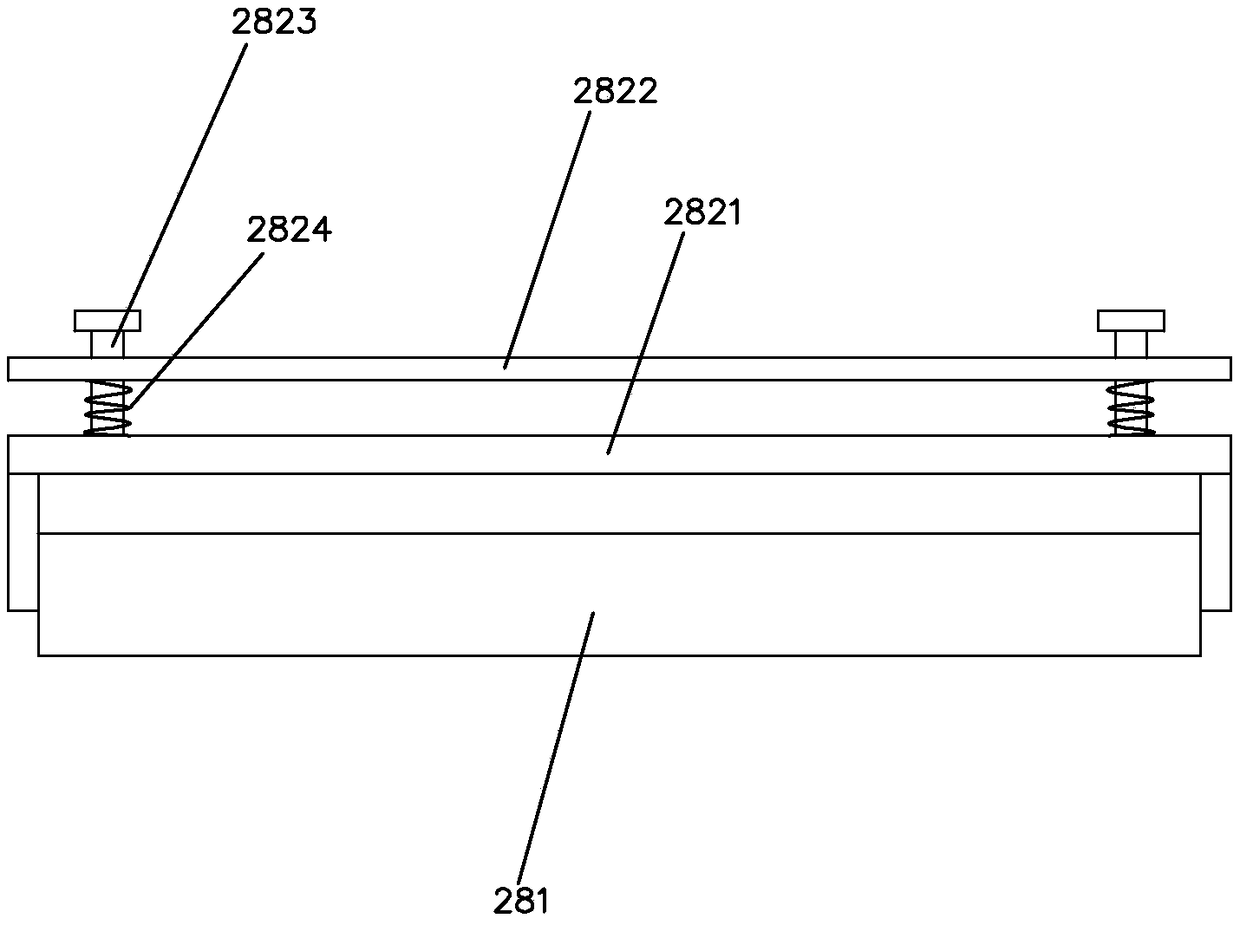

A non-structural free-form surface grinding device

ActiveCN110695809BImprove sanding qualityGuaranteed contact forceGrinding wheel securing apparatusGrinding feed controlSurface finishControl manner

The invention discloses a non-structure freeform curved surface grinding device. Due to the arrangement of a pressing floating mechanism, a six-dimensional force sensor, an active control mechanism and a six-degree-of-freedom manipulator, stress conditions of a plurality of dimensions of a grinding head can be measured in real time through the six-dimensional force sensor. Different active and passive compliance control modes can be adopted by a controller according to the change of the stress conditions in the grinding process, the speed of responding to polishing force changes in the grinding process is improved, the contact force between a grinding head and the ground surface in the grinding process can be kept within a certain reasonable range all the time, and meanwhile, the directionof the grinding force is always in the vertical direction of the ground curved surface. By controlling the running track of the six-degree-of-freedom manipulator, the grinding track of the grinding head is adjusted, the non-structure freeform curved surface of a part to be machined is ground, grinding force control is carried out, the grinding efficiency and the surface finish are effectively improved, the labor intensity is reduced, and meanwhile, the part grinding quality is improved.

Owner:ANHUI POLYTECHNIC UNIV

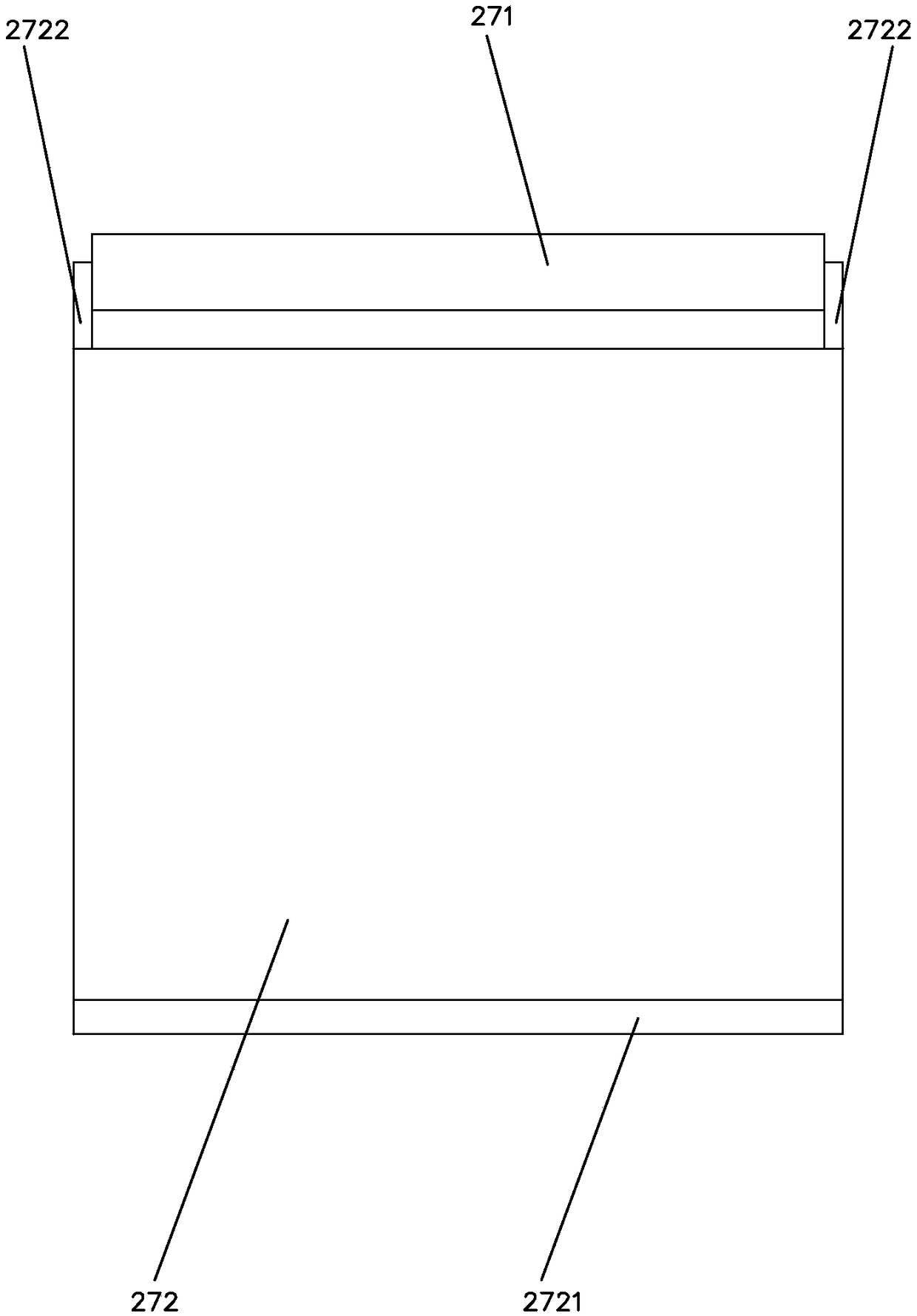

A ball cage cage automatic detection system

ActiveCN104897102BIncrease profitGuaranteed contact forceUsing optical meansMechanical engineeringEngineering

The invention discloses an automatic detection system for a ball cage holder, and the system comprises a rack, a sucking disc, a measuring head support, a camera, a camera support, a sliding seat, a sliding rail, a sliding seat cylinder, measuring tools, and a main control machine. During measurement, the sucking disc absorbs the holder, and the sliding seat cylinder pushes the sliding seat to enable the holder to move to a measurement position. The holder is positioned in a movement process, and the two measuring tools achieve one-time precision measurement. Meanwhile, the camera also achieves the precision detection of the holder. Afterwards, the sliding seat cylinder pushes the sliding seat to enable the holder to be separated from the measuring jaws of the two measuring tools. A sucking disc transmission device drives the holder to rotate twice, and the camera achieves the precision detection of the distance between two adjacent holes of the holder. The above process is carried out twice, thereby completing the detection of the holder.

Owner:ZHEJIANG UNIV OF TECH

High-density contact point connecting device

ActiveCN110034440AGuaranteed contact forceHigh densityCoupling contact membersCouplings bases/casesElectrical and Electronics engineeringHigh density

The invention provides a high-density contact point connecting device, and the device comprises a plug connector and a socket connector, wherein the plug connector comprises a first insulating body and a plurality of first terminals, the first insulating body is provided with a column body part, and the plurality of first terminals are arranged on the column body part. The socket connector comprises a second insulating body and a plurality of second terminals, wherein the second insulating body is provided with a cylinder part, an accommodating space is formed in the cylinder part, and the plurality of second terminals are arranged on the cylinder part. The column body part of the plug connector can be inserted into the accommodating space of the socket connector, and the plug connector and the socket connector can rotate relatively, so that the first contact parts of the first terminals are clamped between the two second contact parts of the second terminals, and the plurality of first terminals and the plurality of second terminals are in contact conduction. Therefore, high-density and high-reliability signal contact points can be generated.

Owner:ZHENGLING PRECISION IND GUANGDONG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com