Automatic detection system for ball cage holder

An automatic detection and cage technology, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of low automation, low detection accuracy, and low detection efficiency, and achieve simple and reliable mechanisms, high detection accuracy, and improved The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

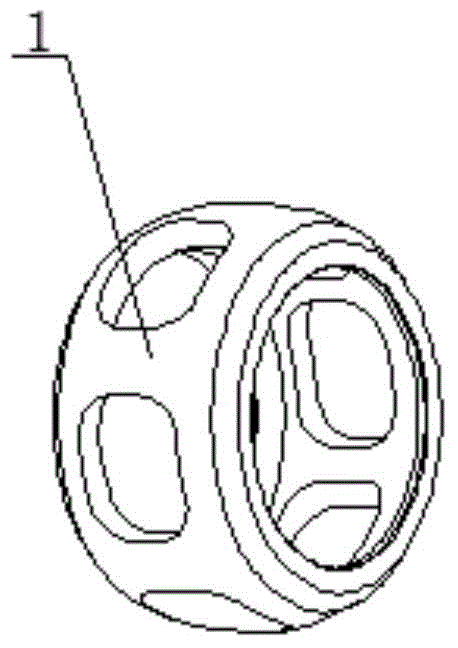

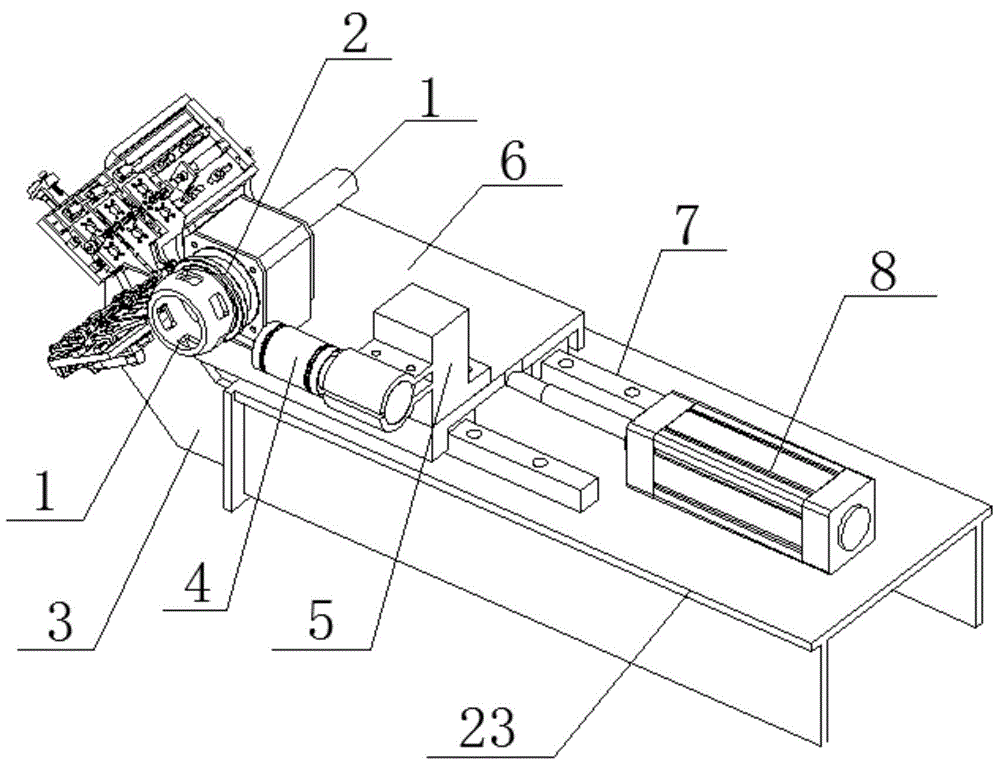

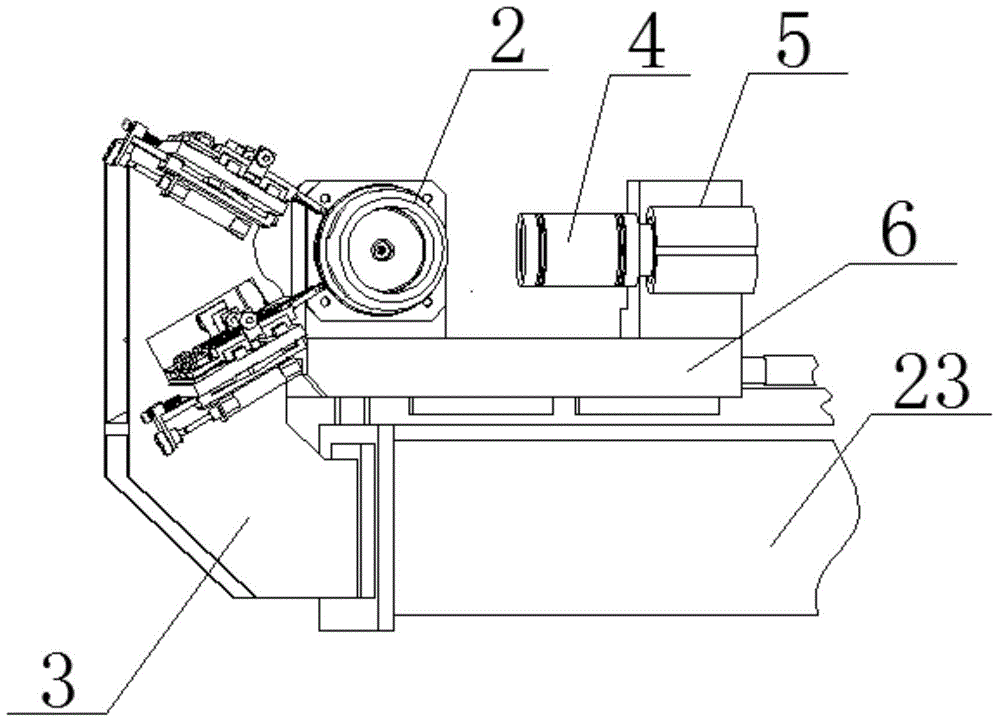

[0027] See attached figure 1 , 2 , 3, 4, 5, 6, an automatic detection system for ball cage cages,

[0028] Including frame 23, suction cup 2, measuring head support 3, camera 4, camera support 5, slide seat 6, slide rail 7, slide seat cylinder 8, measuring tools and main control machine.

[0029] The frame 23 is fixedly connected with the slide rail 7, the slide seat 6 is sleeved on the slide rail 7, and one end thereof is connected with the cylinder rod of the slide seat cylinder 8 fixed on the frame 23, Sliding along the slide rail 7 under the action of the slide cylinder 8; the measuring head bracket 3 is fixed on the end face of the frame 23 near the side of the sliding seat 6, and two measuring tools are fixed on the measuring head bracket 3; the sliding base The camera bracket 5 is installed on the side near the cylinder on the 6, and the camera brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com