Double-motor driving structure of double-rotor type compressor and control method of double-motor driving structure

A dual-motor drive and compressor technology, applied in the field of compressors, can solve the problems of pollution, reduce the life and performance of the stack, and stack poisoning, and achieve the effects of avoiding oil leakage, improving accuracy and reducing contact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

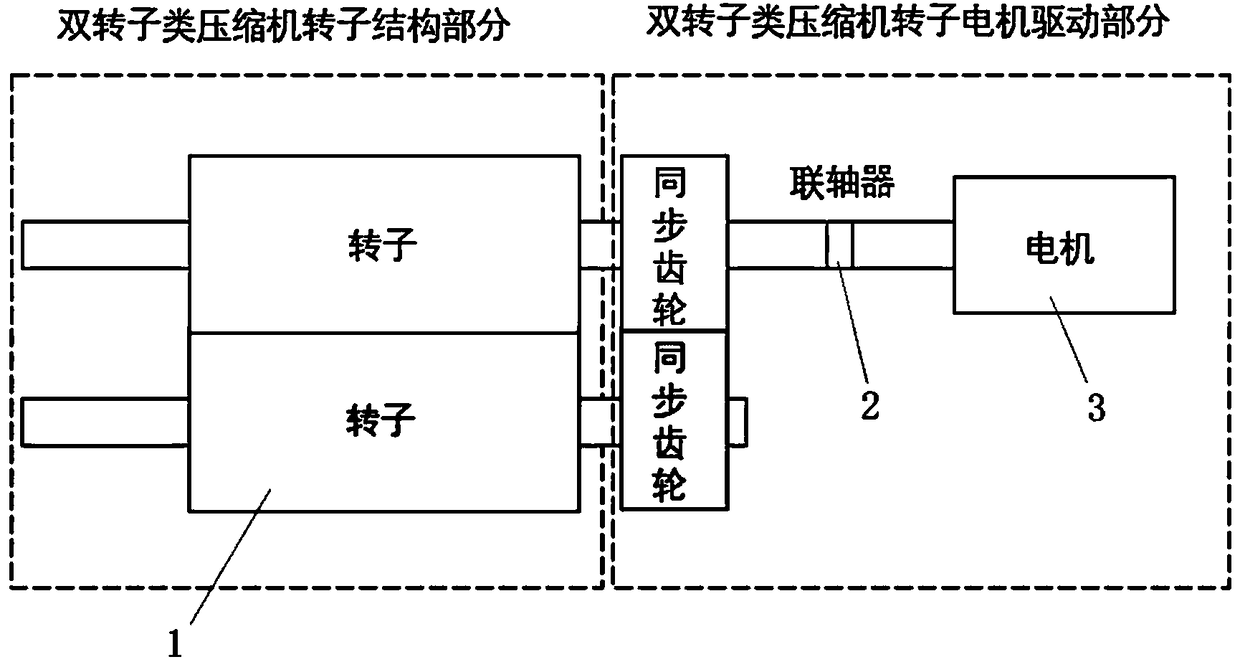

[0027] see figure 1 , the present invention can be modified on the basis of the traditional double-rotor compressor driving structure. In the original driving structure, the motor is connected to a certain rotor, and the other rotor is driven by synchronous gears. This driving method increases oil pollution.

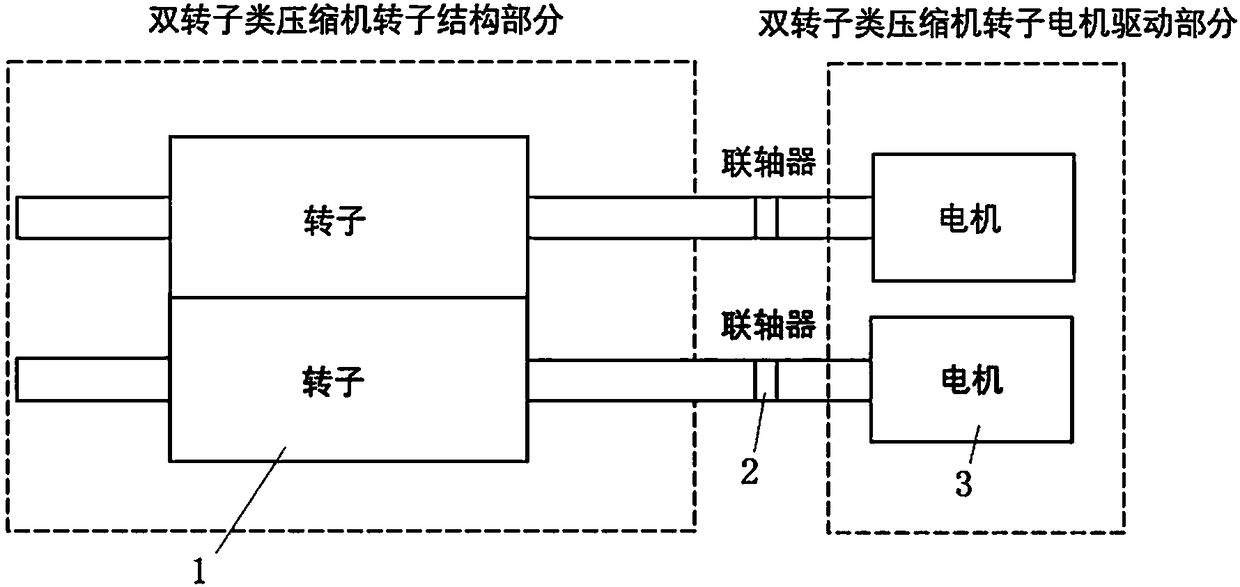

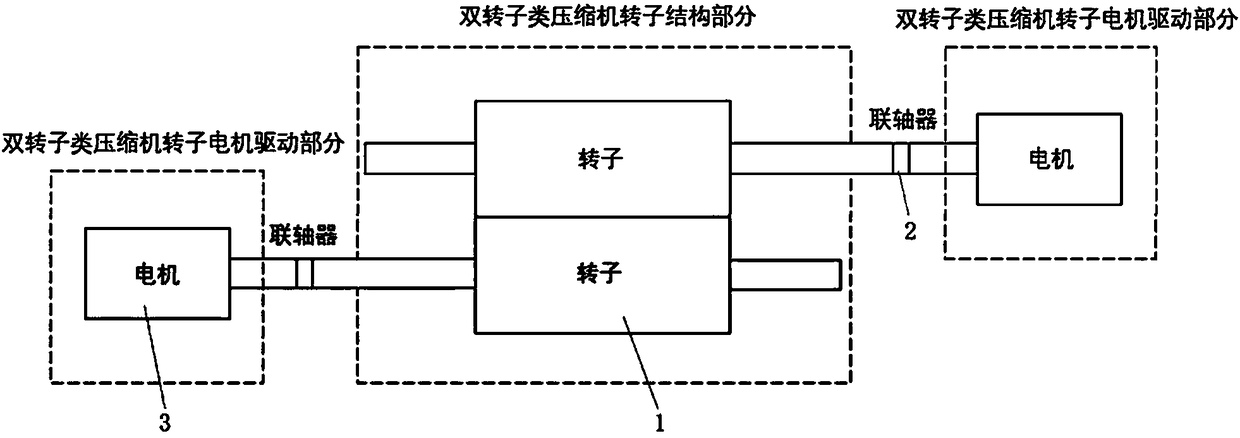

[0028] see Figure 2-3 , the present invention adopts a double-motor drive structure, two motors 3 are respectively connected to two compressor rotors 1 through a coupling 2, and the two motors 3 are arranged on the same side of the two compressor rotors 1 in a row-by-row manner or adopt a fork Arranged in rows on opposite sides of the two compressor rotors 1, synchronous gears are omitted, thereby avoiding the problem of oil leakage.

[0029] see Figure 4-8 , the control method of double-motor drive structure of the present invention, comprises the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com