Single-cylinder type injection device

An injection device and single-cylinder technology, applied in the field of single-cylinder injection devices, can solve the problems of slow backward movement of the injection piston, affecting the normal operation of the equipment, lack of guiding devices, etc., so as to reduce the occupied space and prevent offset , space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings.

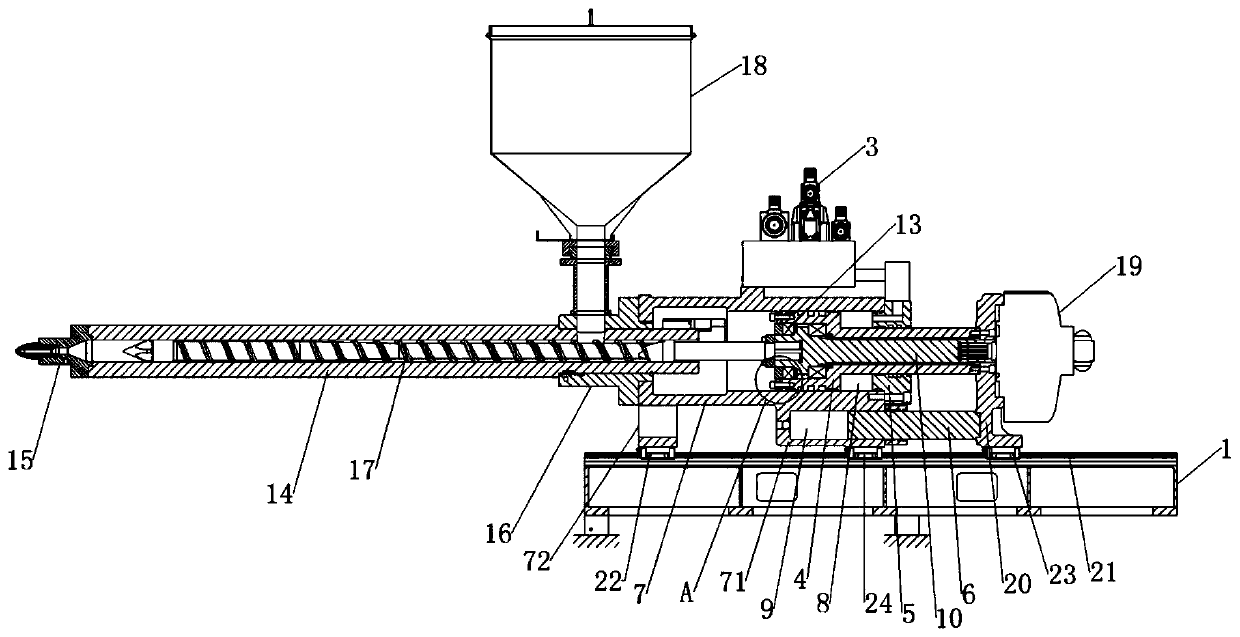

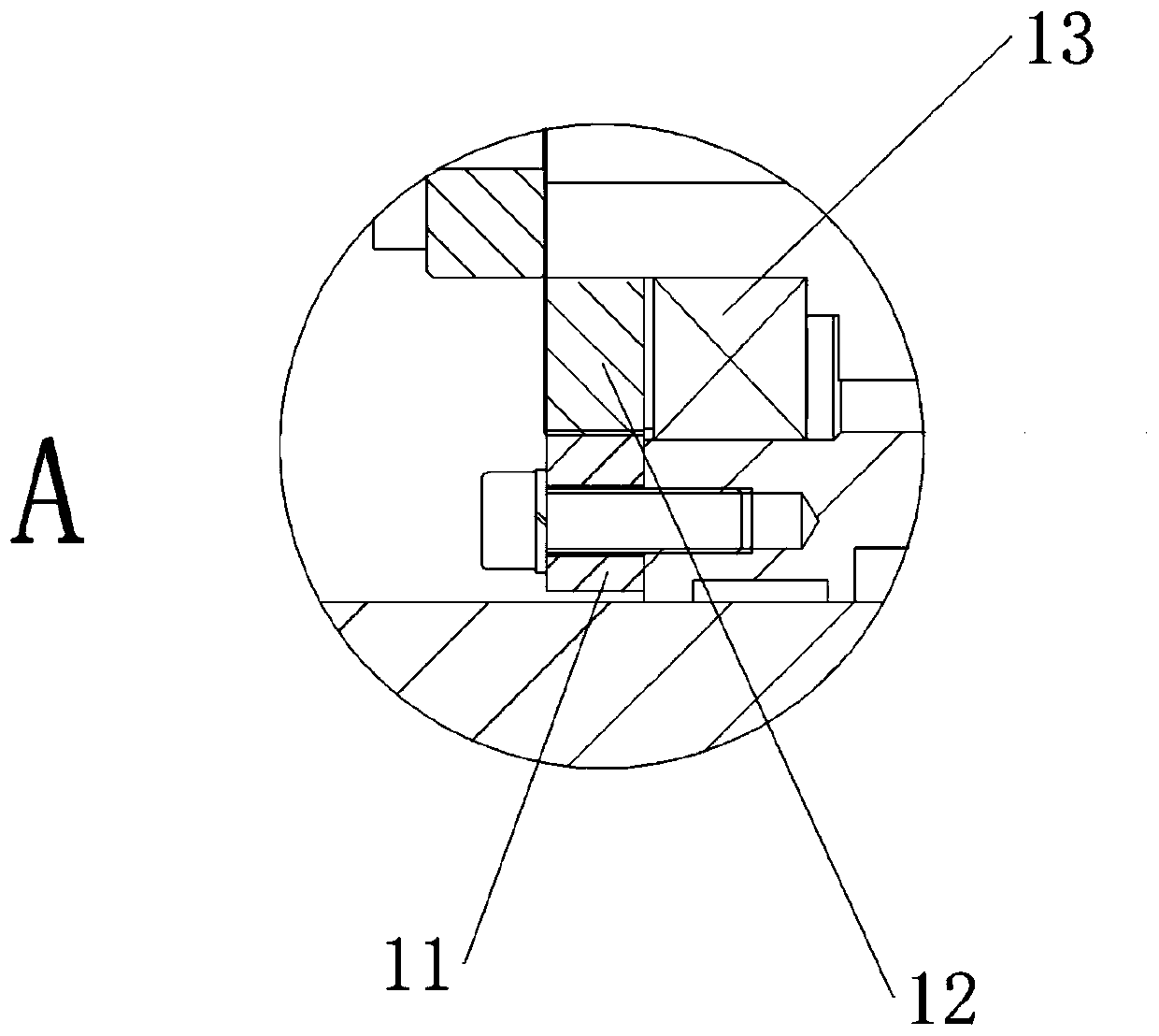

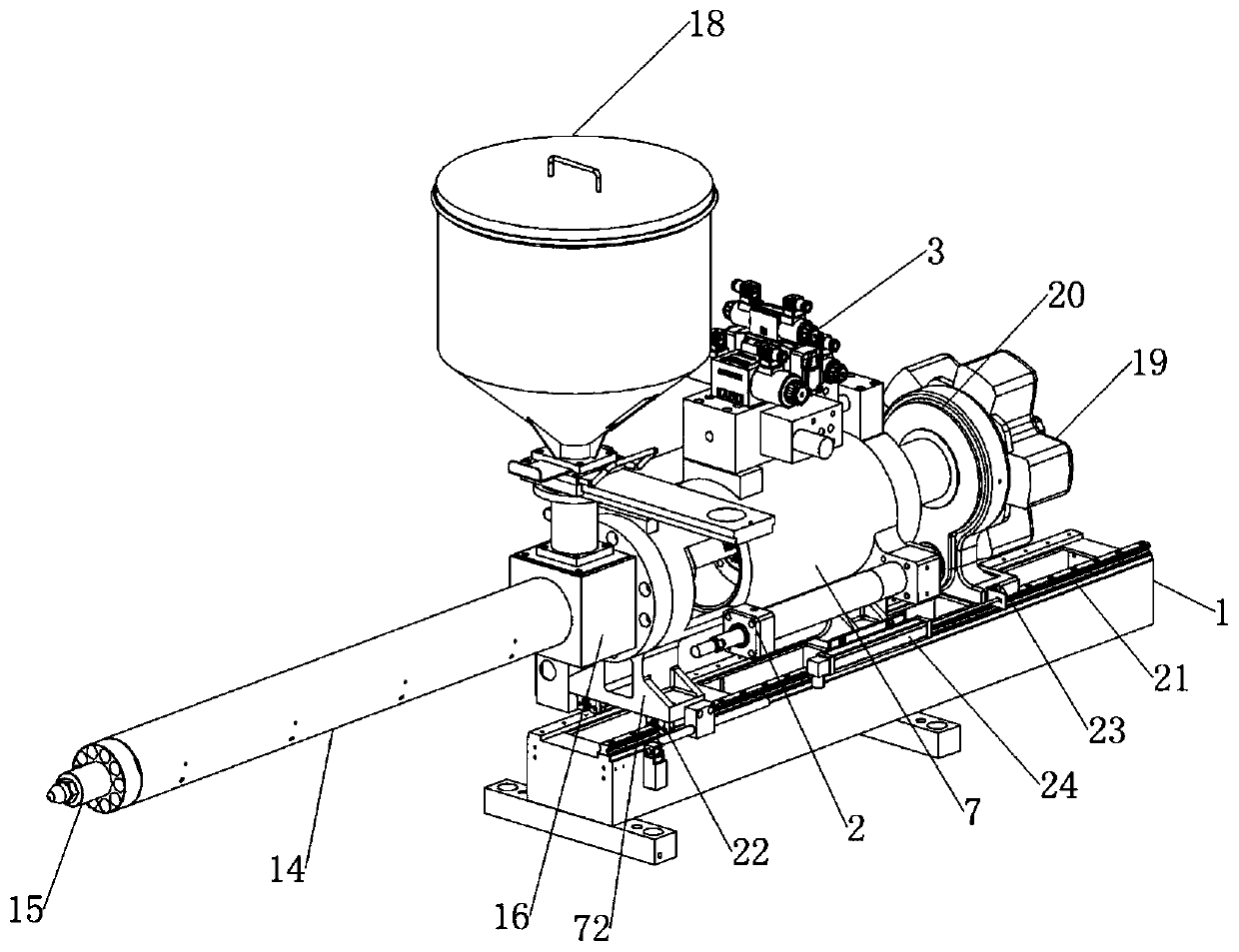

[0022] reference Figure 1-5 , A single-cylinder injection device of the present invention includes a bracket 1, an oil cylinder 2, an oil circuit integrated block 3, an injection seat 7, an extension section 71, an injection piston 4, an ejection plunger 6, an injection back end cover 5, and a motor 19. The transmission shaft 10, the bearing 13, the locking ring 12, the fixed ring 11, the screw 17, the barrel 14, the nozzle 15, the hopper assembly 18, the motor seat 20 and the barrel seat 16.

[0023] The bracket 1 includes two linear guide rails 21, and the two linear guide rails 21 are installed on the bracket 1 symmetrically.

[0024] The injection seat 7 is installed on the support 1. The injection seat 7 is provided with a first slider 22 and a third slider 24. There are two first sliders 22, two third sliders 24, and two first sliders. 22 are matched with the two linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com