Caliper body, caliper body machining method and method for assembling brake with caliper body

A processing method and caliper technology, applied in the direction of brake type, axial brake, brake parts, etc., can solve the problems of low assembly efficiency, complicated caliper manufacturing, and difficult assembly, so as to achieve high processing efficiency and practical tools Wide range, convenient clamping and positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

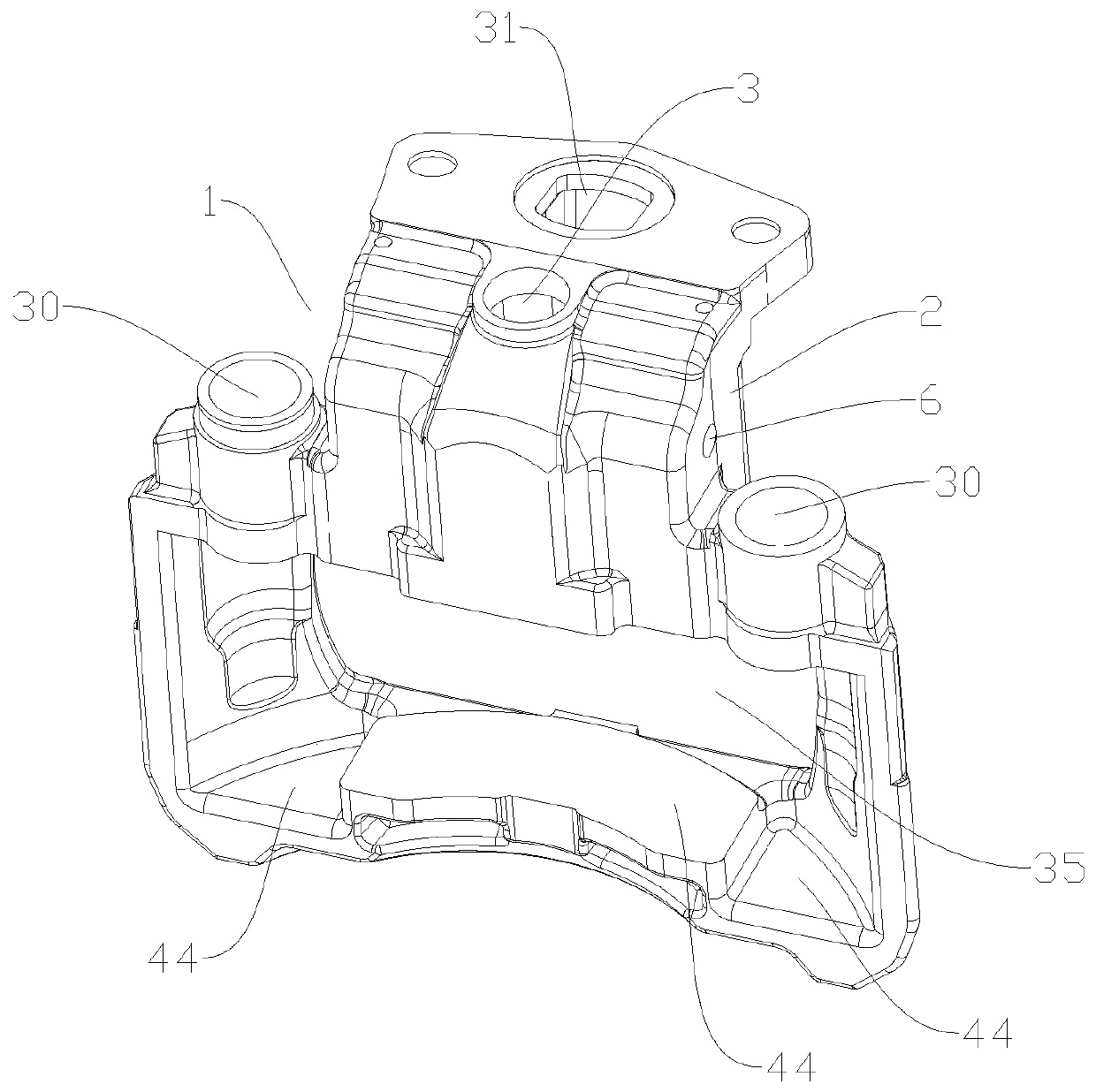

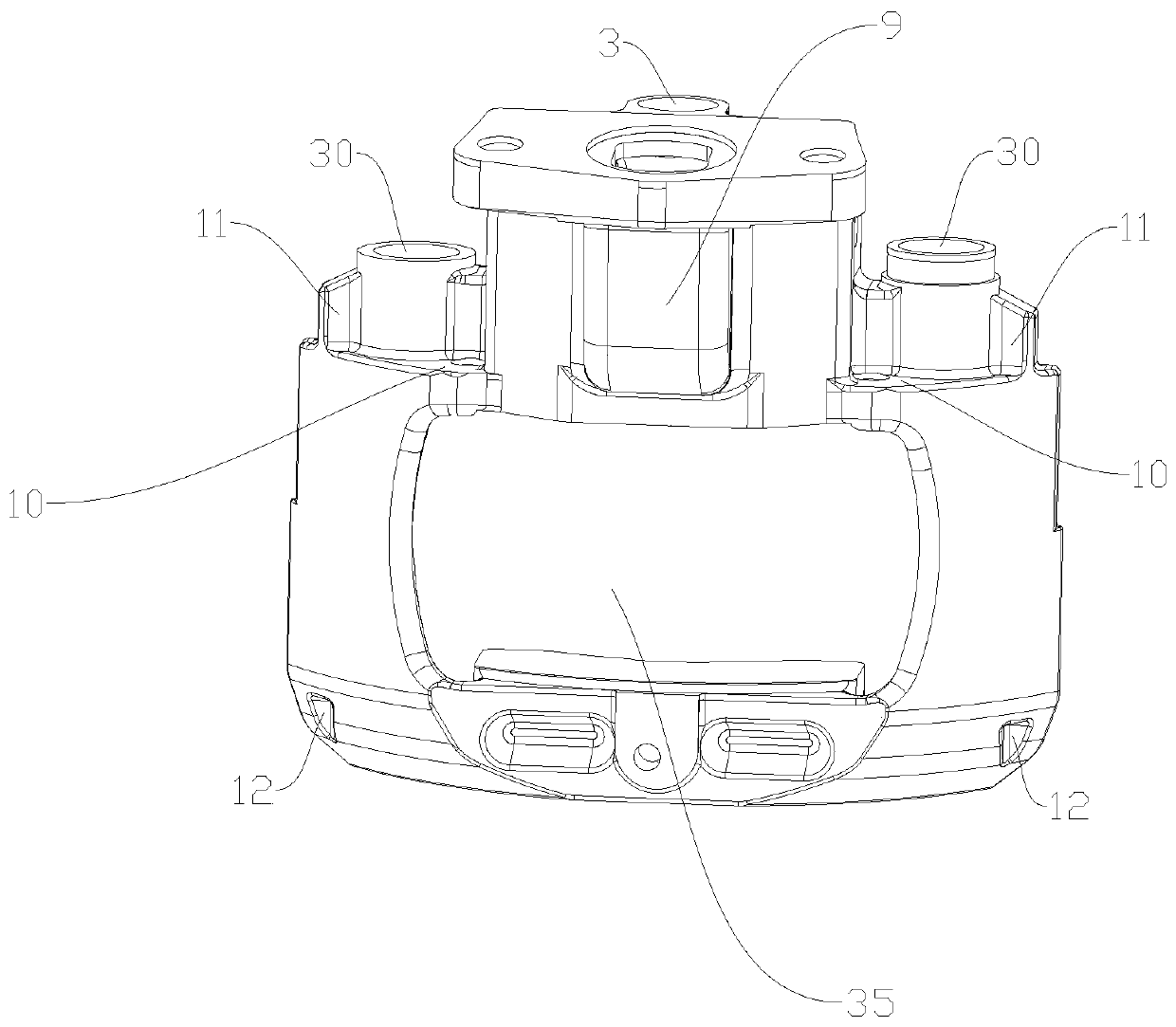

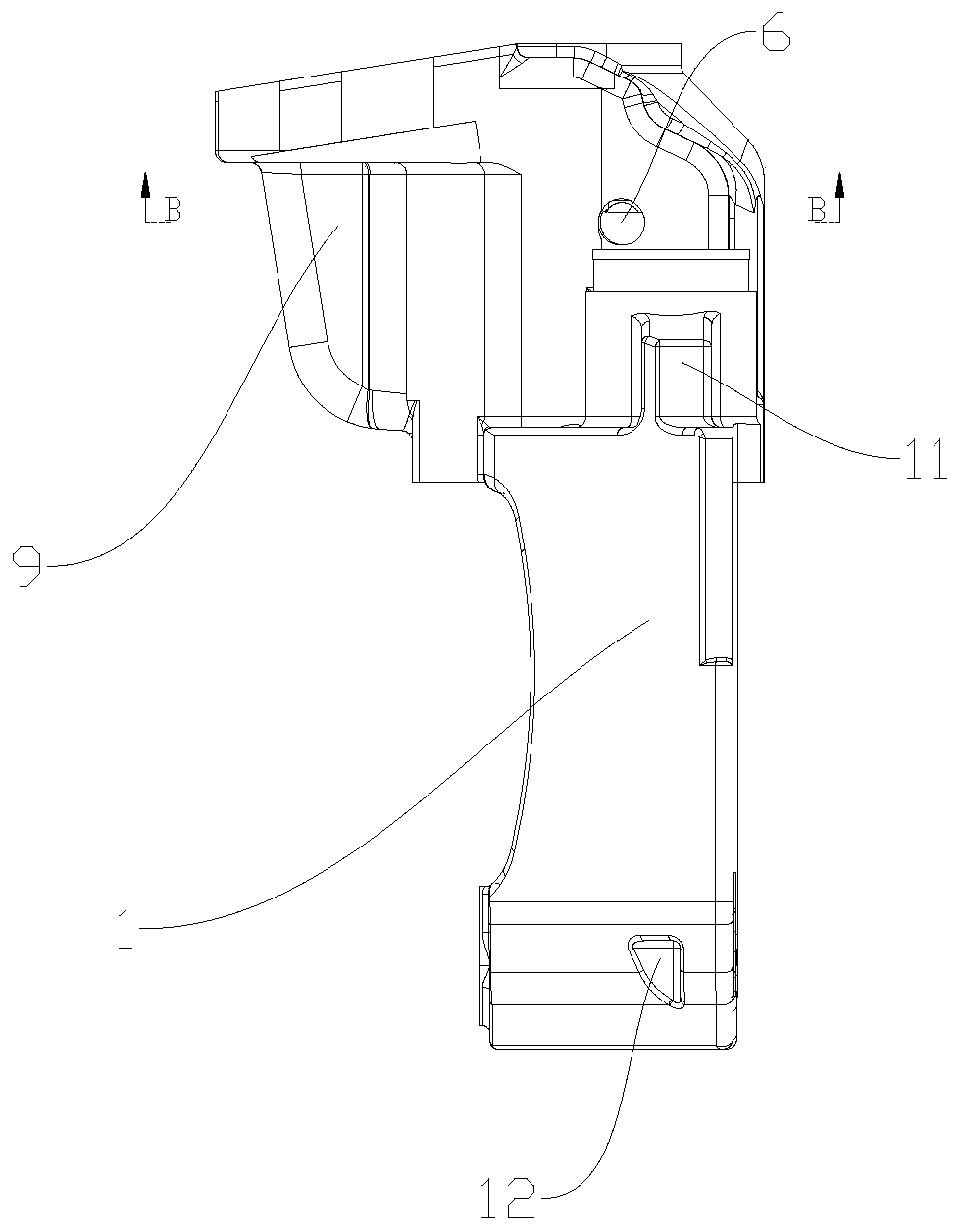

[0061] Such as Figure 1 to Figure 4 As shown, the present embodiment describes the structure of the caliper body 1 and the structure of the pneumatic disc brake equipped with the caliper body 1 . In this implementation, the brake is a single push rod type air disc brake. The pliers body 1 is integrally formed, and the pressure arm assembly installed in the pliers body 1 is integrally casted. The up, down, left, right, front and back directions of the following are figure 1 as the benchmark. The first assembly cavity 2 for assembling the pressure arm assembly is formed inside the caliper body 1. The upper end surface of the first assembly cavity 2 is provided with a shaft hole 3. The center of the shaft hole 3 is the braking center of the brake. When assembling, the adjuster assembly The adjusting rod of 17 is assembled in the axle hole 3. A force-receiving part 4 is formed in the first assembly cavity 2 , and the force-receiving part 4 is integrally formed as a boss exten...

Embodiment 2

[0080] This embodiment discloses a processing method for processing the pliers body 1 in the first embodiment.

[0081] First of all, it is necessary to limit the degrees of freedom of the caliper body 1 during the clamping process. The clamping process utilizes a horizontal machining center for processing. The first assembly cavity 2 comprises the second cavity 9 protruding to the back, the left and right sides of the first assembly cavity 2 are provided with a positioning platform 10, the height of the positioning platform 10 is less than the height of the upper end surface of the first assembly cavity 2, and the positioning platform 10 is formed with a pin hole 30, and the outside of the pin hole 30 is provided with a positioning shoulder 11, and the positioning shoulder 11 is integrally formed on the positioning table 10. In this embodiment, the pin hole 30 is a pipe fitting, and the pipe fitting and the pliers 1 is integrally formed, and a reinforcing rib is formed betwe...

Embodiment 3

[0094] The difference between this embodiment and Embodiment 1 is that: the process hole 6 is formed initially when the pliers body 1 is cast and formed, and then processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com