Square hole plate surface for fixing wiring harness of box rectifier module

A rectifier module and fixed wire technology, which is applied in the direction of casing/cabinet/drawer components, electric vehicles, electrical components, etc., can solve the trouble of installing and maintaining the rectifier module of the charging pile box, waste materials, increase costs, etc. problems, to achieve the effect of increasing labor costs, saving materials, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

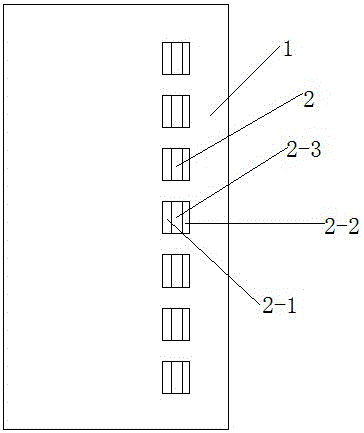

[0009] refer to figure 1 , a box rectifier module fixed wire harness square hole plate, which includes a plate 1, characterized in that the plate is provided with square holes 2 from top to bottom, the distance between the square holes is the same, and the square holes are divided into left holes 2-1 and the right hole 2-2, between the left hole 2-1 and the right hole 2-2 is a solid plate surface 2-3, and the left hole and the right hole of the square hole are the inlet and outlet of the cable tie.

[0010] In view of the need to weld the wire harness fixing bracket to fix the wire harness in the past, which increases labor costs and wastes more materials, this invention uses its own board wall to punch a board surface with square holes, and uses cable ties to fix the wire harness, saving materials. Compared with the old-fashioned Box body welding harness fixing frame saves cost.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap