An oil control valve characterized by end portion oil supply

An oil control valve and oil supply technology, which is applied to control the pressure of lubricants, valve details, multi-way valves, etc., can solve the problems of easy fatigue and fracture of the filter screen 7 and increased bending stress of the filter screen 7, so as to achieve less fatigue. The effect of fracture, hydraulic pressure reduction, and durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

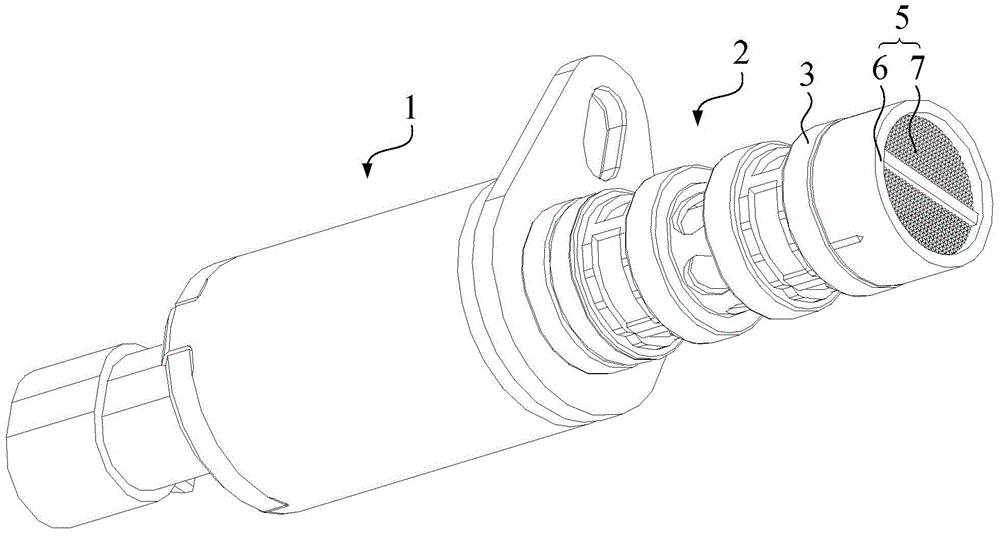

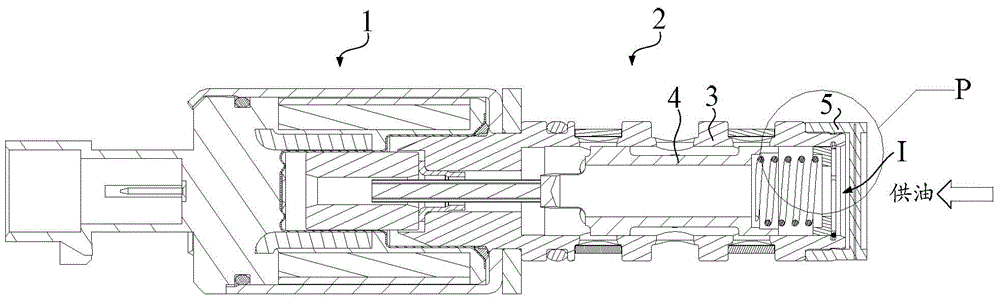

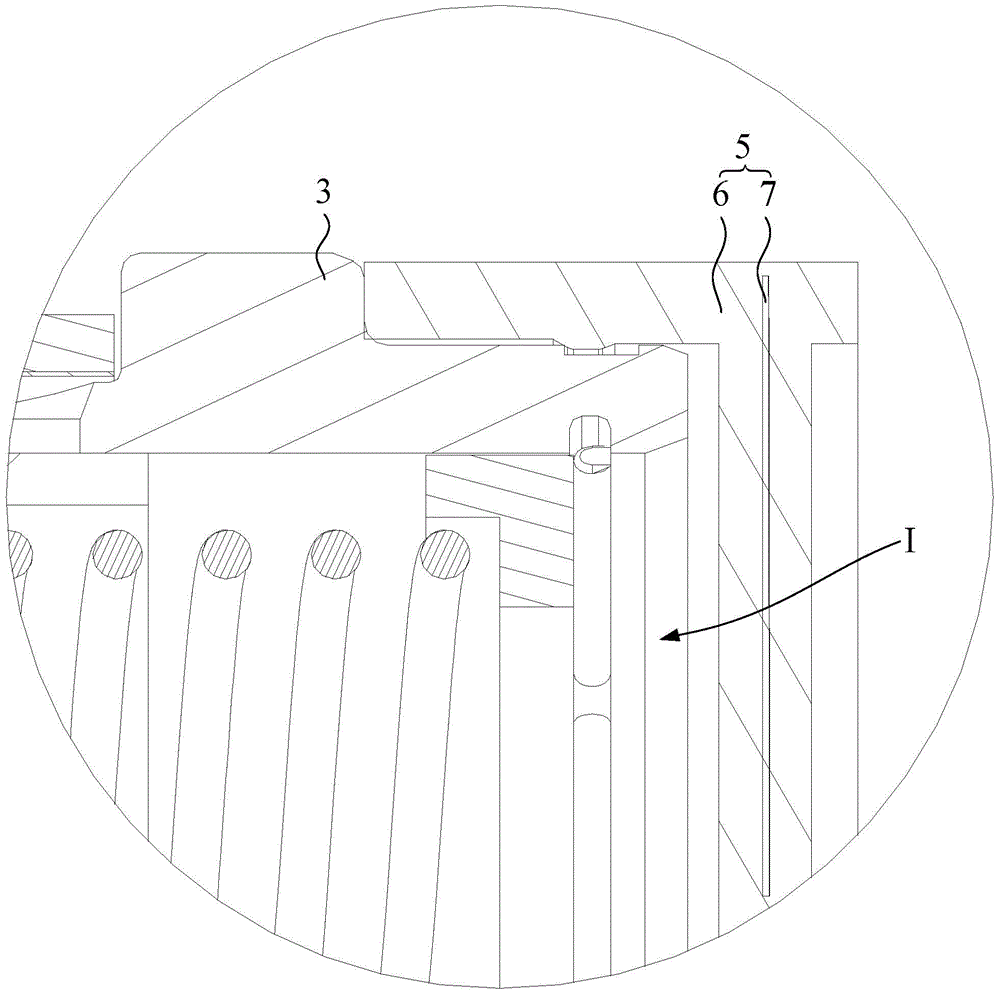

[0022] combine Figure 4 to Figure 5 As shown, the oil control valve for oil supply at the end of this embodiment includes two parts: a proportional electromagnet 10 and a hydraulic body 20 . Wherein, the proportional electromagnet 10 includes a movable armature 100 . The hydraulic body 20 includes: a valve body 200; a push rod 201, a movable piston 202, a compression spring 203, a spring seat 204, and a snap ring 205 arranged in sequence along the axial direction in the valve body 200; a filter 210; an elastic member 220.

[0023] The valve body 200 has an oil inlet I located at the axial end, and a shoulder 206 protruding radially outward on the outer peripheral surface of the valve body 200, and the other end of the valve body 200 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com