Accurate hydraulic classifier

A hydraulic classifier, precise technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of affecting the operation, easy to block the discharge port, shorten the service life of the classifier, etc., to improve the classification accuracy, The effect of promoting discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

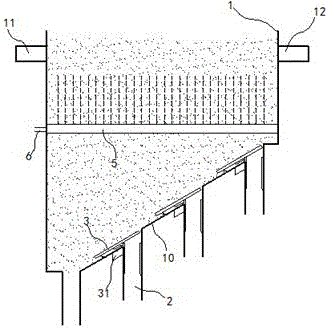

[0022] exist figure 1 , figure 2 In the shown embodiment, this precise hydraulic classifier includes a classification chamber 1, a feed pipe 11 and an overflow pipe 12 are installed on the top of the classification chamber 1, and a discharge pipe 2 is installed at the bottom of the classification chamber 1;

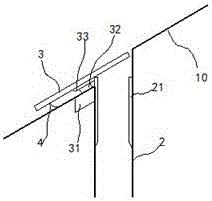

[0023] The bottom plate 10 of the classifying chamber 1 is a sloping plate, and the sloping plate is inclined upward along the traveling direction of the material;

[0024] A filter disc 3 is installed at the interface between each discharge pipe 2 and the base plate 10, and the filter disc 3 blocks the interface between the discharge pipe 2 and the base plate 10; the radius of the filter disc 3 is twice the radius of the discharge pipe 2;

[0025] Each filter disc 3 is made of mesh material, and the size of the mesh on each filter disc 3 gradually decreases along the traveling direction of the material;

[0026] The filter disc 3 can freely rotate around its own rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com