Machine tool having inspection function for deteriorated state of spindle

A degraded state and inspection function technology, applied in the field of machine tools, can solve problems such as inability to inspect bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

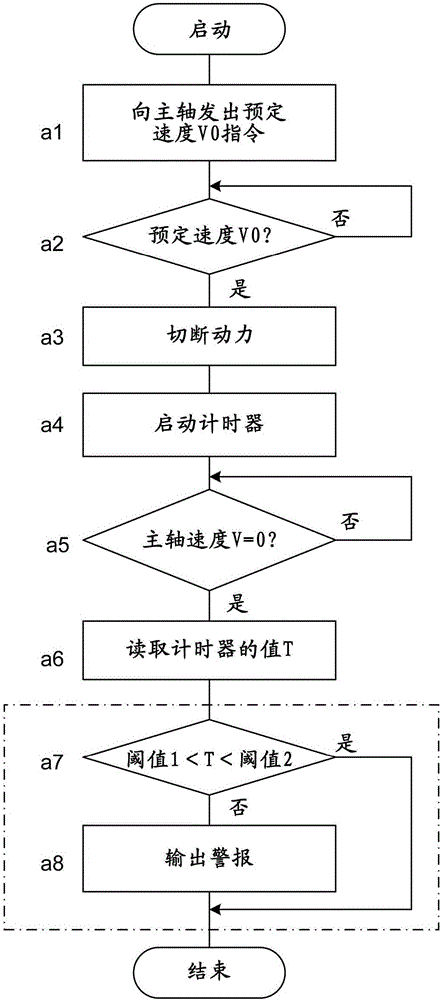

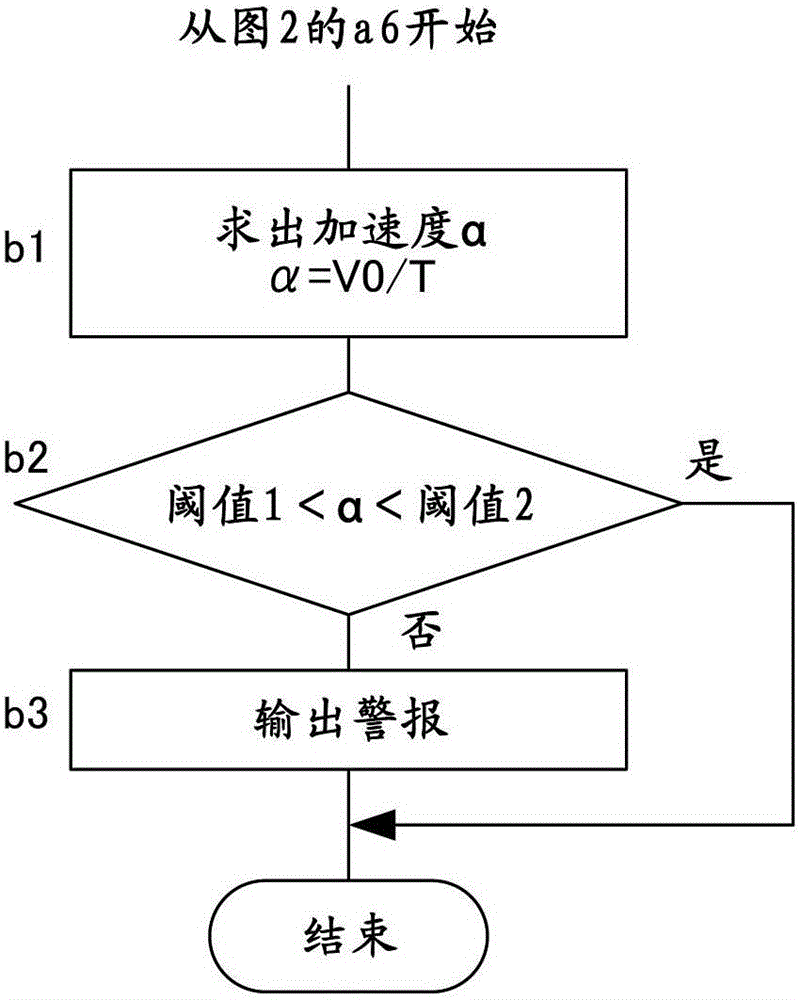

[0027] The present invention is a machine tool equipped with a function of inspecting the deterioration state of the main shaft of the machine tool, and has no change in hardware configuration from conventional machine tools. The present invention is applied to a machine tool having a spindle holding a tool for machining a workpiece. In the present invention, software for checking the deterioration state of the spindle is stored in a control device such as a numerical control device for controlling a machine tool, and the deterioration state of the spindle is detected by performing the inspection process of the deterioration state of the spindle using the software.

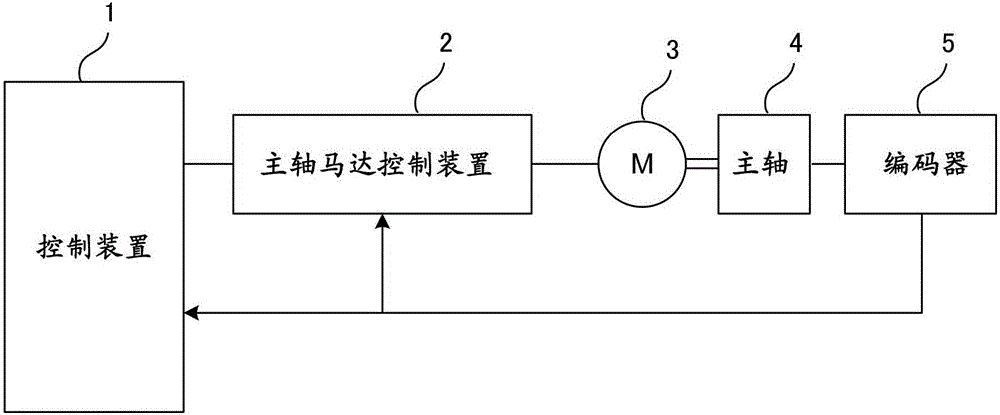

[0028] figure 1 It is a block diagram of main parts of one embodiment of the present invention. Only the main parts of the parts related to the present invention are shown. Symbol 1 is a control device such as a numerical control device for controlling a machine tool, symbol 2 is a spindle motor control device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com