Trench wall structure of pneumatic tire tread pattern

A tread pattern, pneumatic tire technology, applied in the direction of tire tread/tread pattern, road tires, tire parts, etc., can solve the problems of abnormal wear, easy to slip, insufficient grip of the tread pattern, etc. Improve wear resistance, increase edge effect, improve grip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

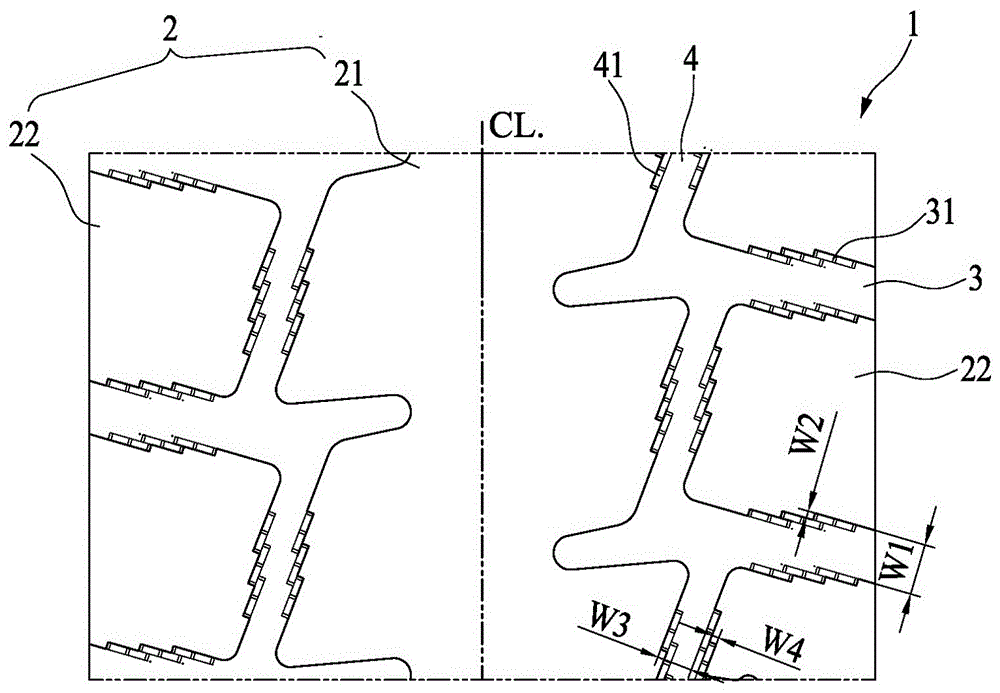

[0019] Such as Figure 1 to Figure 4 As shown, the present invention discloses a groove wall structure of a tread pattern of a pneumatic tire, wherein the vertical direction is the tire circumferential direction, the transverse direction is the tire axial direction, and the tire tread 1 is composed of a plurality of pattern block groups 2, wherein the pattern The block group 2 includes a central block 21 and shoulder blocks 22 located on both sides of the central block 21 , grooves are formed between each shoulder block 22 and the central block 21 , thereby ensuring the wet performance of the tire.

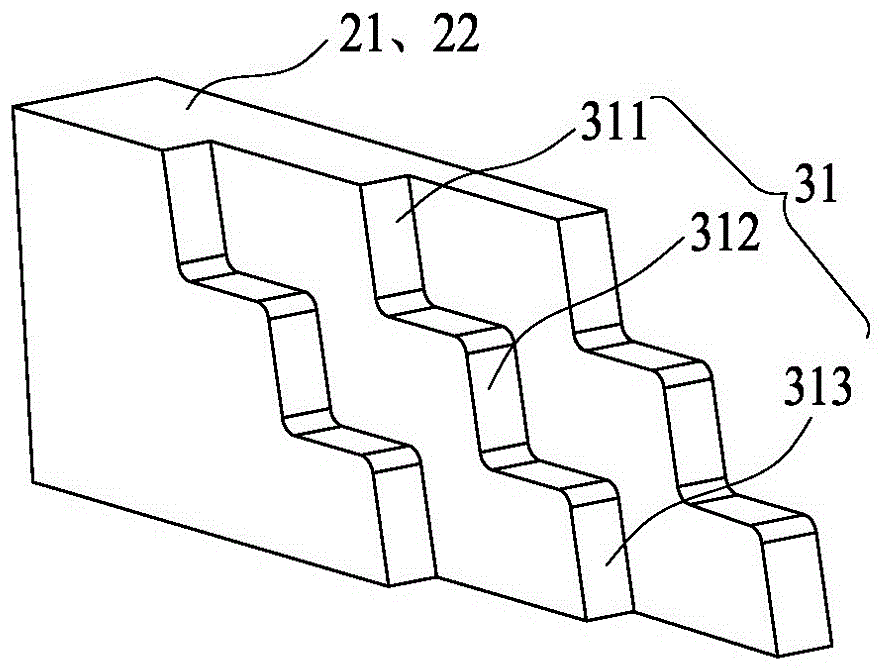

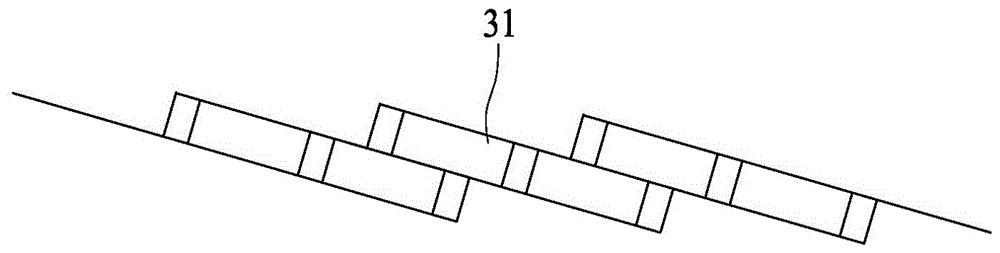

[0020] In order to improve the grip of the tire tread pattern, the two side walls of each pattern groove are provided with multi-step three-dimensional groove walls along the length direction of the groove, and the multi-step shape of the three-dimensional groove walls on the two side walls of the same pattern groove is Set instead.

[0021] In order to further improve the grip o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com