Tire

A tire and tire crown technology, applied in road tires, tire parts, tire treads/tread patterns, etc., can solve problems such as difficulty in adjusting rolling resistance and wet performance, and achieve rolling resistance and ensure wet conditions. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

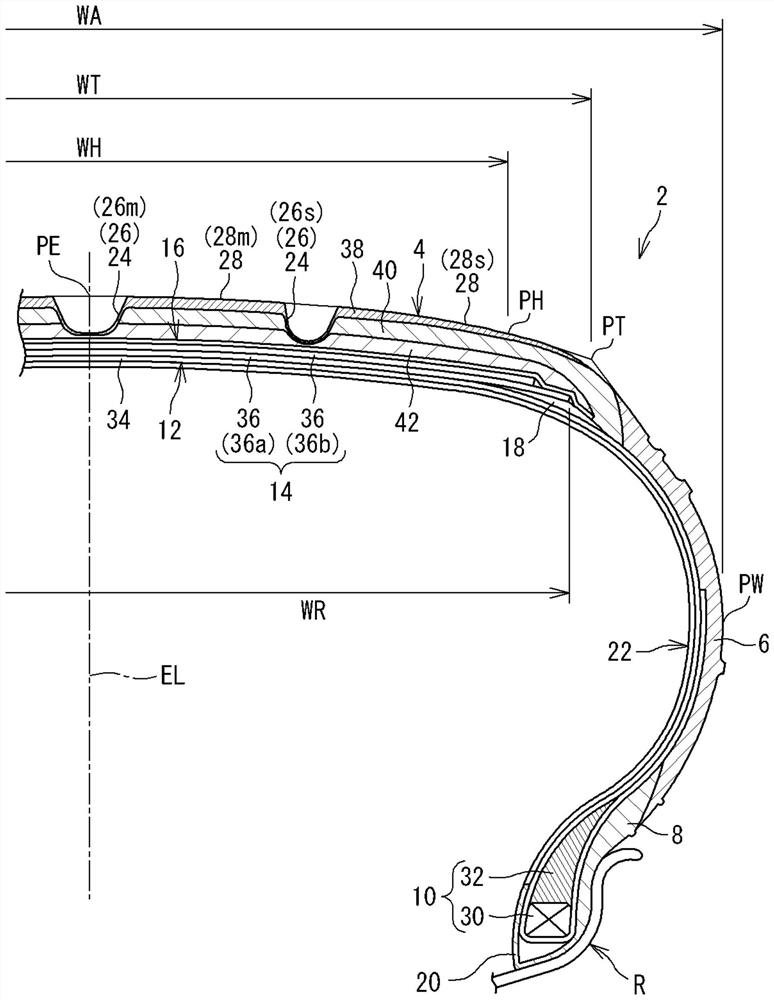

[0142] Pneumatic tires for passenger cars (tire size = 205 / 55R16) were obtained with figure 1 The basic structure shown has the specifications shown in Table 1 below.

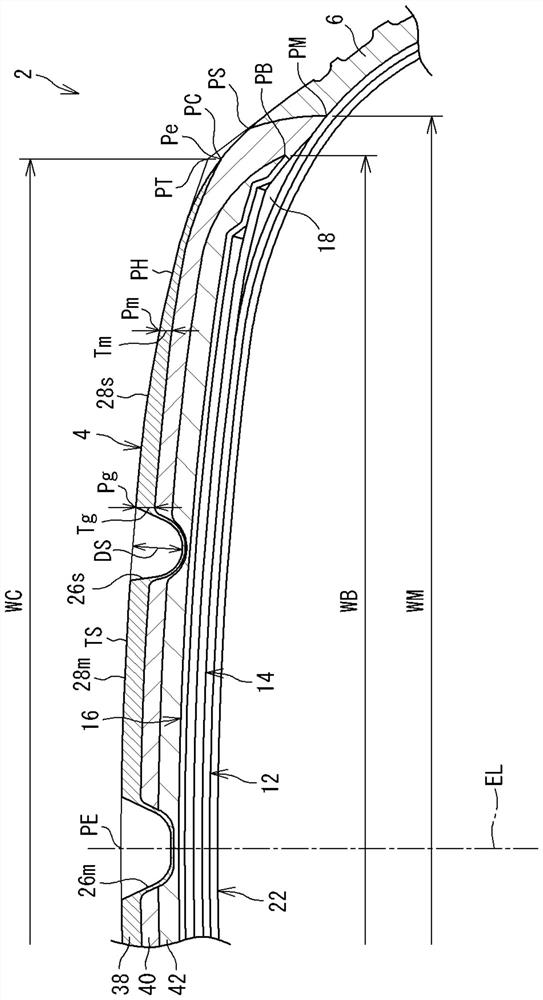

[0143] used with a crown layer, an intermediate layer and a base layer, with image 3 Tread of the composition shown. The loss tangent LTc at 30° C. of the crown layer was 0.27. The loss tangent LTm at 30° C. of the intermediate layer was 0.12. The loss tangent LTb at 30° C. of the base layer was 0.10.

[0144] The difference between the axial width WC of the crown layer and the width WT of the tread (WC-WT) was 0 mm. The difference (WB-WT) between the axial width WB of the base layer and the width WT of the tread was 0 mm. The difference between the axial width WM of the intermediate layer and the axial width WB of the base layer (WM-WB) was 10 mm.

[0145]In the shoulder land portion, the ratio Rg of the thickness Tg of the crown layer on the shoulder circumferential groove side to the effective groove ...

Embodiment 2

[0149] A tire of Example 2 was obtained in the same manner as in Example 1, except that the ratio Re and the difference (WC-WT) were as shown in Table 1 below.

Embodiment 3

[0151] A tire of Example 3 was obtained in the same manner as in Example 1 except that the ratio RM was as shown in Table 1 below.

[0152] [Rolling Resistance Coefficient (RRC)]

[0153] Using a rolling resistance tester, the sample tire was driven on a drum at a speed of 80 km / h under the following conditions, and the rolling resistance coefficient (RRC) at that time was measured. The results are shown in Table 1 below using an index of 100 in Comparative Example 1. The smaller the value, the lower the rolling resistance of the tire. Rim: 16×6.5J Internal pressure: 210kPa Longitudinal load: 4.82kN

[0154] [Wet performance of new tires (WET)]

[0155] A new sample tire was assembled on a rim (size = 16 x 6.5 J), filled with air, and the internal pressure of the tire was adjusted to 230 kPa. The tires were mounted on a test vehicle (passenger car). The test vehicle was driven on a test route on a wet road surface (water film thickness=1.4 mm). The test vehicle was brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com