pneumatic tire

A technology for pneumatic tires and tires, applied in heavy tires, tire parts, tire treads/tread patterns, etc., can solve the problems of reduced riding comfort, uneven wear, etc., and achieve the effect of low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

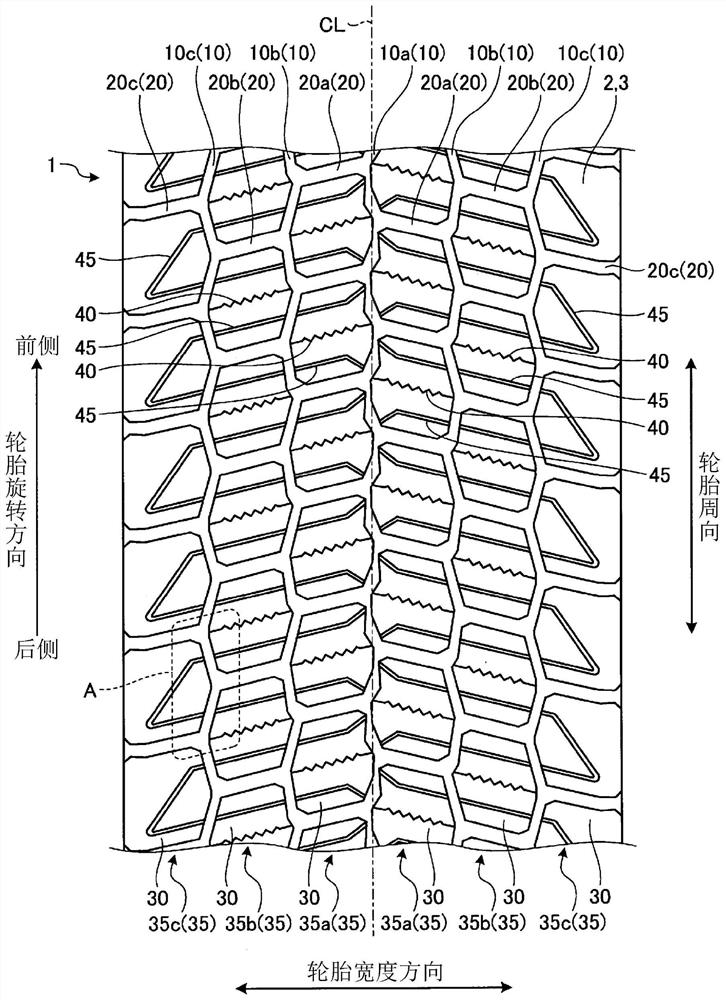

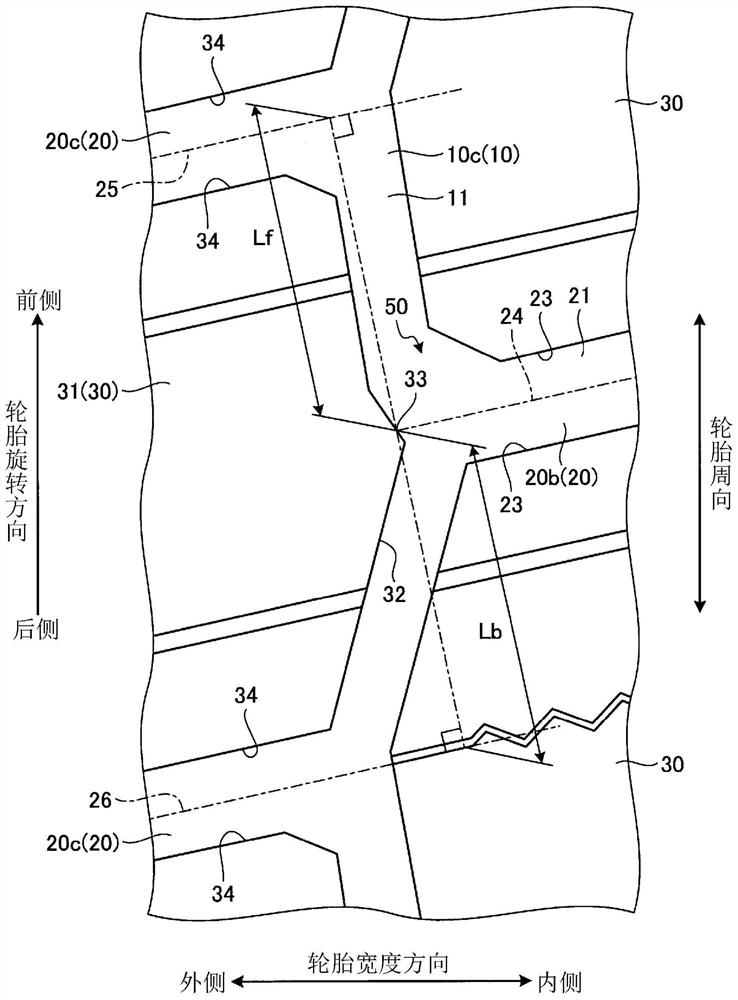

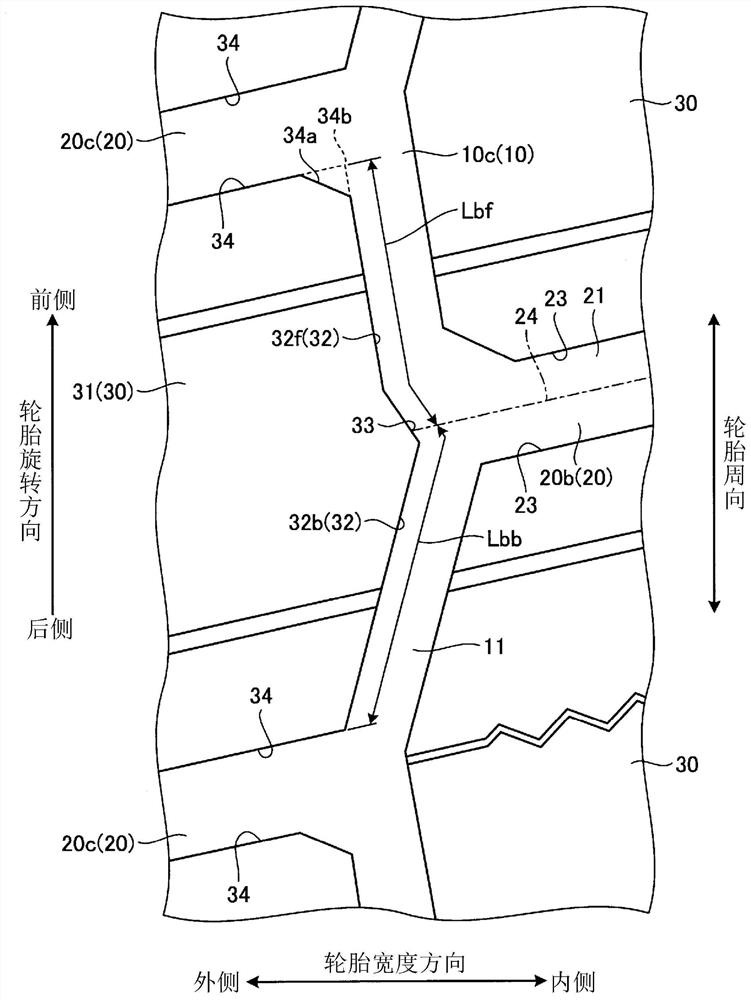

[0027] Hereinafter, embodiments of the pneumatic tire of the present invention will be described in detail based on the drawings. It should be noted that the present invention is not limited by the present embodiment. Furthermore, the components of the following embodiments include elements of those skilled in the art can be replaced and easily desirable, or substantially the same elements.

[0028] In the following description, the tire width direction refers to a direction parallel to the rotation axis of the pneumatic tire, and the tire width direction refers to the direction in which the tire width direction towards the tire equator line, and the tire width direction refers to the direction of the tire width direction The opposite direction of the direction of the equatorial line. Further, the tire radial refers to the direction orthogonal to the rotary axis of the tire, and the tire circumference refers to the direction in which the rotation of the rotary axis is centered.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com