Cymbals

A tension device, disc-type technology, applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the poor effect of removing flying impurities, insufficient support of the lower metal tension disc, and poor braking effect and other problems, to achieve good application prospects, improve the effect of impurity removal, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

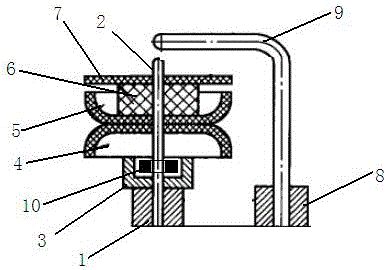

[0014] like figure 1 As shown, the disk-type tension device of the present invention, the disk-type tension device, includes a first fixed seat 1, a mandrel 2 is installed in the first fixed seat 1, and a top of the first fixed seat 1 is provided with A support base 3, the support base 3 is sleeved on the mandrel 2, and a lower metal tension disc 4, an upper metal tension disc 5, and an upper tension washer 6 are successively installed above the support base 3, and the lower metal tension disc 4. The upper metal tension disc 5 and the upper tension washer 6 are sequentially nested on the mandrel 2 from bottom to top. The upper metal tension disc 5 is also provided with a buffer felt block 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com