Transfer vehicle for photovoltaic cleaning robot

A technology for cleaning robots and transfer vehicles, applied in the direction of lifting devices, lifting frames, etc., can solve the problem of only cleaning one row of photovoltaic modules, and achieve the effect of reducing procurement costs and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

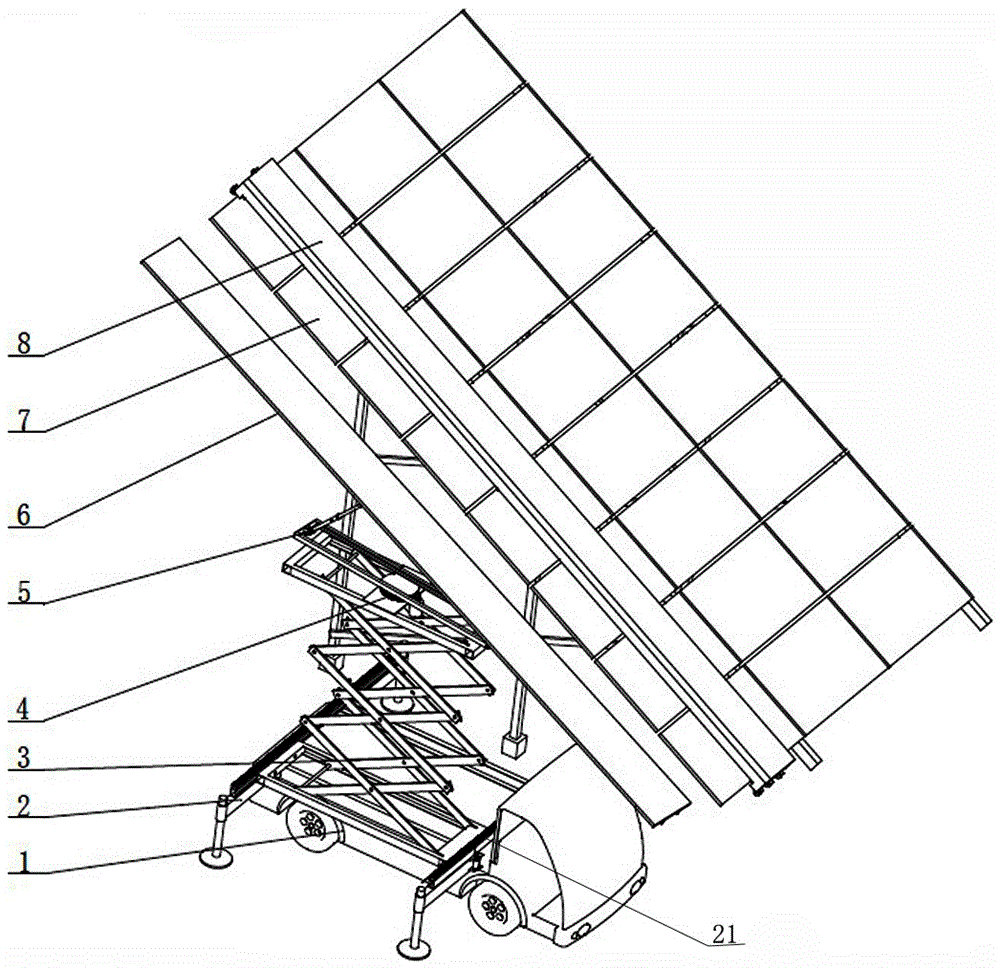

[0023] Such as figure 1 As shown, the photovoltaic cleaning robot transfer vehicle includes a chassis 1, and walking wheels are installed under the chassis 1. Longitudinal beams are fixed on the left and right sides of the chassis 1. A folding chassis 2 is installed on the longitudinal beams. Self-propelled lifting mechanism 3, self-propelled lifting mechanism 3 can move left and right on the foldable chassis 2, self-propelled lifting mechanism 3 is equipped with slewing support 4, slewing support 4 is equipped with turning mechanism 5, turning mechanism 5 The guide rail pair is connected with the sliding tray 6, and a travel switch is arranged on the sliding tray.

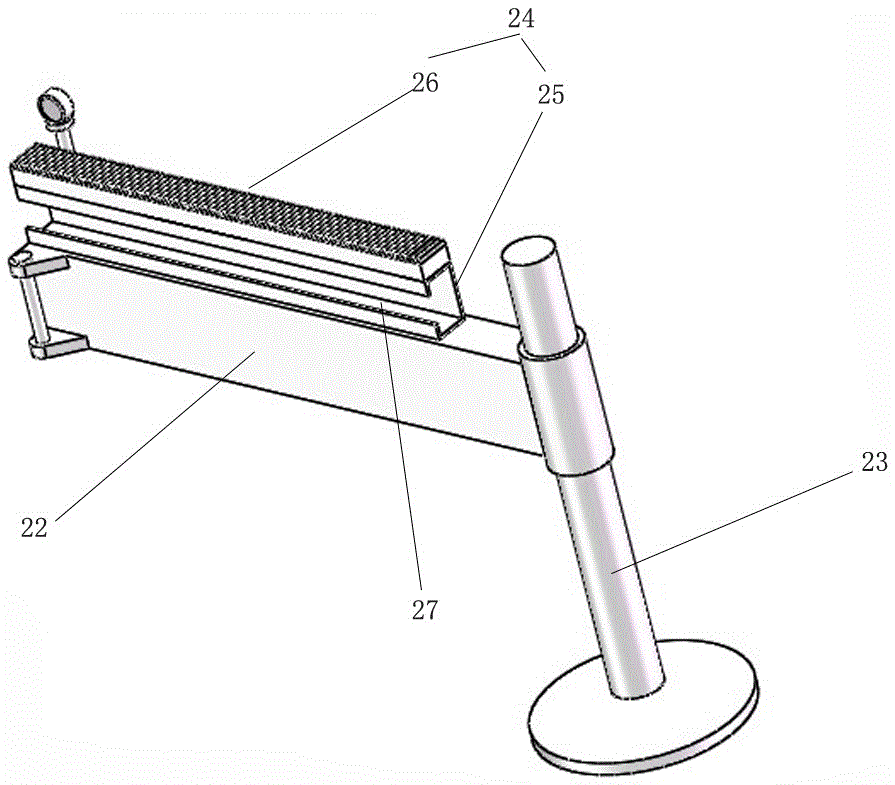

[0024] Such as figure 2 As shown, the foldable underframe 2 includes two parallel rails 21, and the two ends of the rails 21 are provided with support mechanisms. One end is fixed to the support leg 23, the other end is hinged to the longitudinal beam, and the support leg 23 is connected to the second oil cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com