Method for controlling acid-zinc ratio of electrolyte in zinc hydrometallurgy electrolysis process

A technology of electrolyte zinc acid and hydrometallurgy zinc, which is applied in the direction of electrolysis process, electrolysis components, photography process, etc., can solve the problem that the flow rate of new liquid and the ratio of electrolytic acid zinc cannot be linearly measured.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

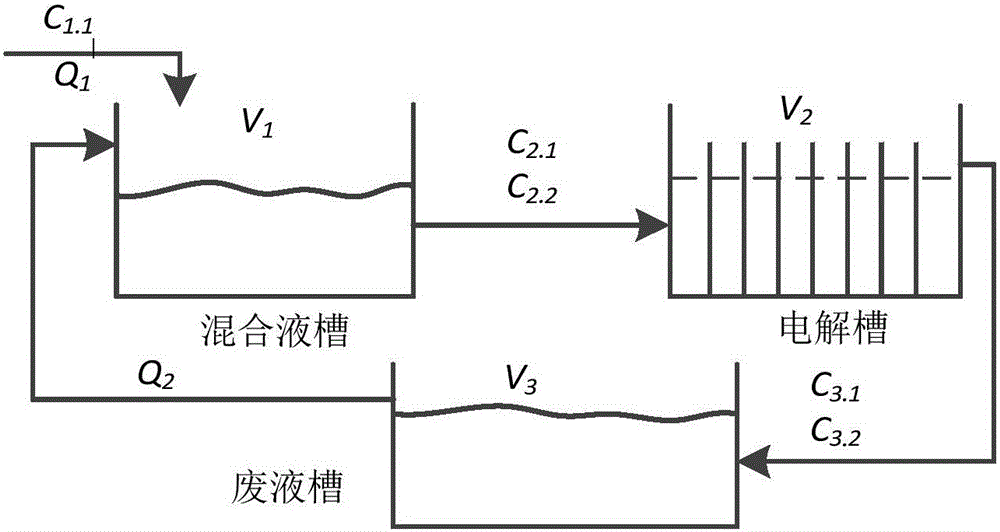

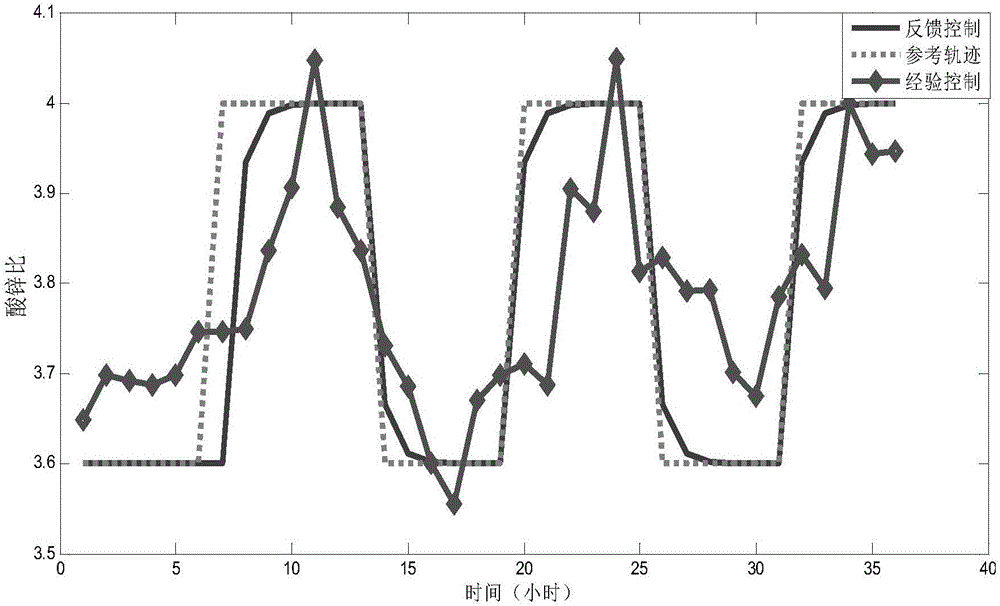

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0037] A method for controlling the zinc-acid ratio of an electrolyte solution in a zinc hydrometallurgy electrolysis process, the specific implementation steps are as follows:

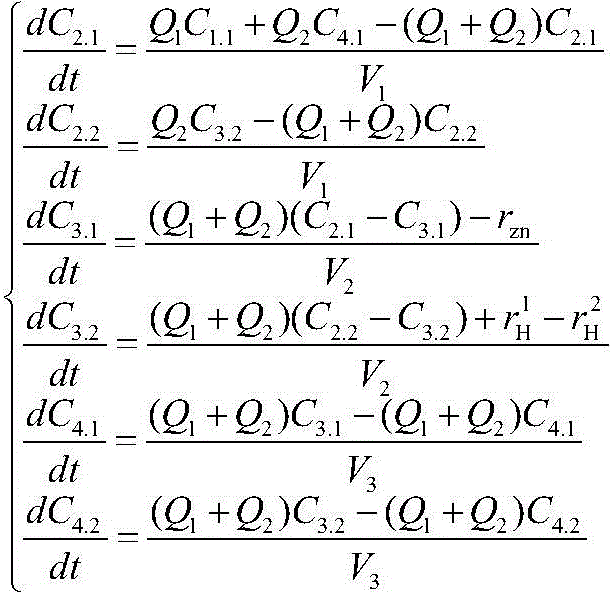

[0038] The first step: online calculation of zinc acid ion concentration in the electrolyte of the zinc electrolysis process

[0039] Step 1: Identify unknown parameters in the current efficiency equation

[0040] Collect data records including current efficiency, current density, electrolyte zinc acid ion concentration, and data items in the on-site production data to form an identification sample set, and use the least square method to identify the five unknown parameters in the equation:

[0041] ε=a 0 +a 1 D+a 2 D. 2 +a 3 D. 3 +a 4 D. 4

[0042] a 0 =62.07268

[0043] a 1 =0.28154

[0044] a 2 =-0.00109

[0045] a 3 =1.9038*10- 6

[0046] a 4 =-1.231*10- ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com