Bridge built-in hollow core force sensor ferrule type tensioning system and method

A technology of force sensor and ferrule type, applied in bridges, bridge materials, bridge construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

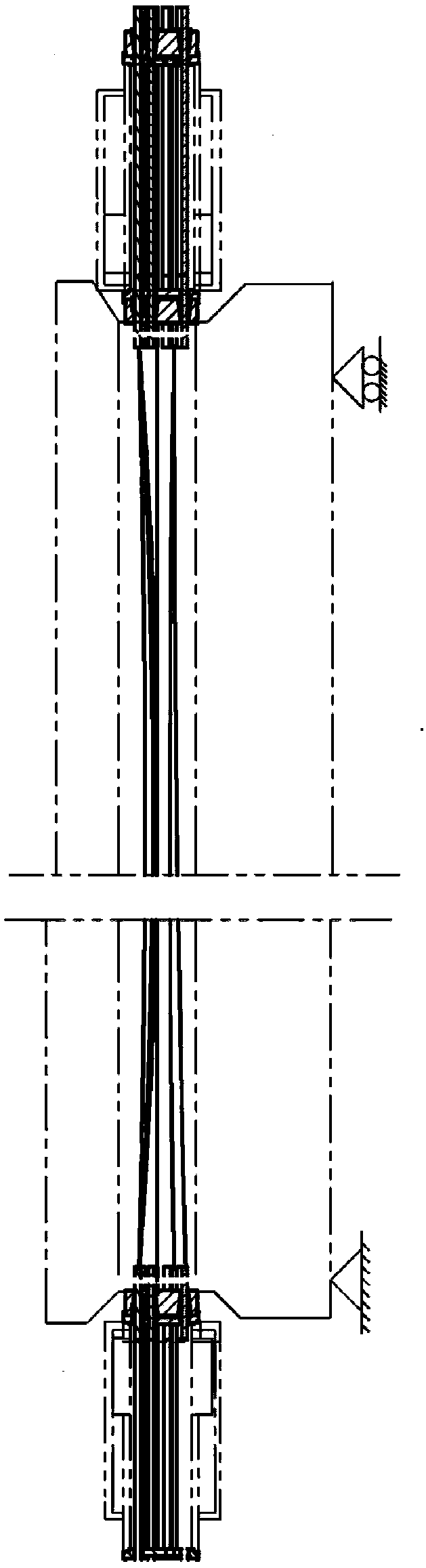

[0051] Such as figure 1 As shown, the steel strands 13 are stretched simultaneously by using the center tensioning cylinders 14 on both sides of the bridge.

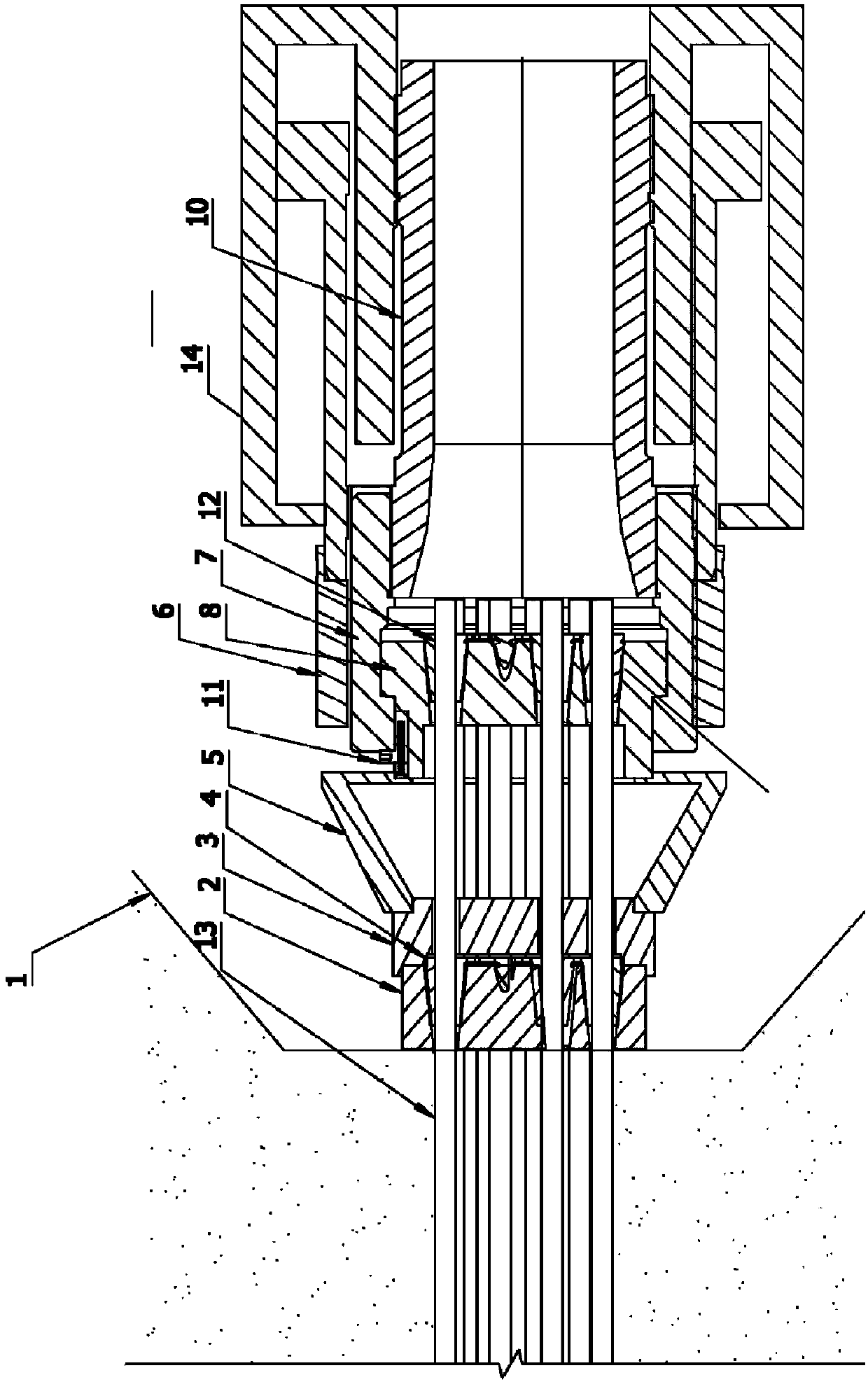

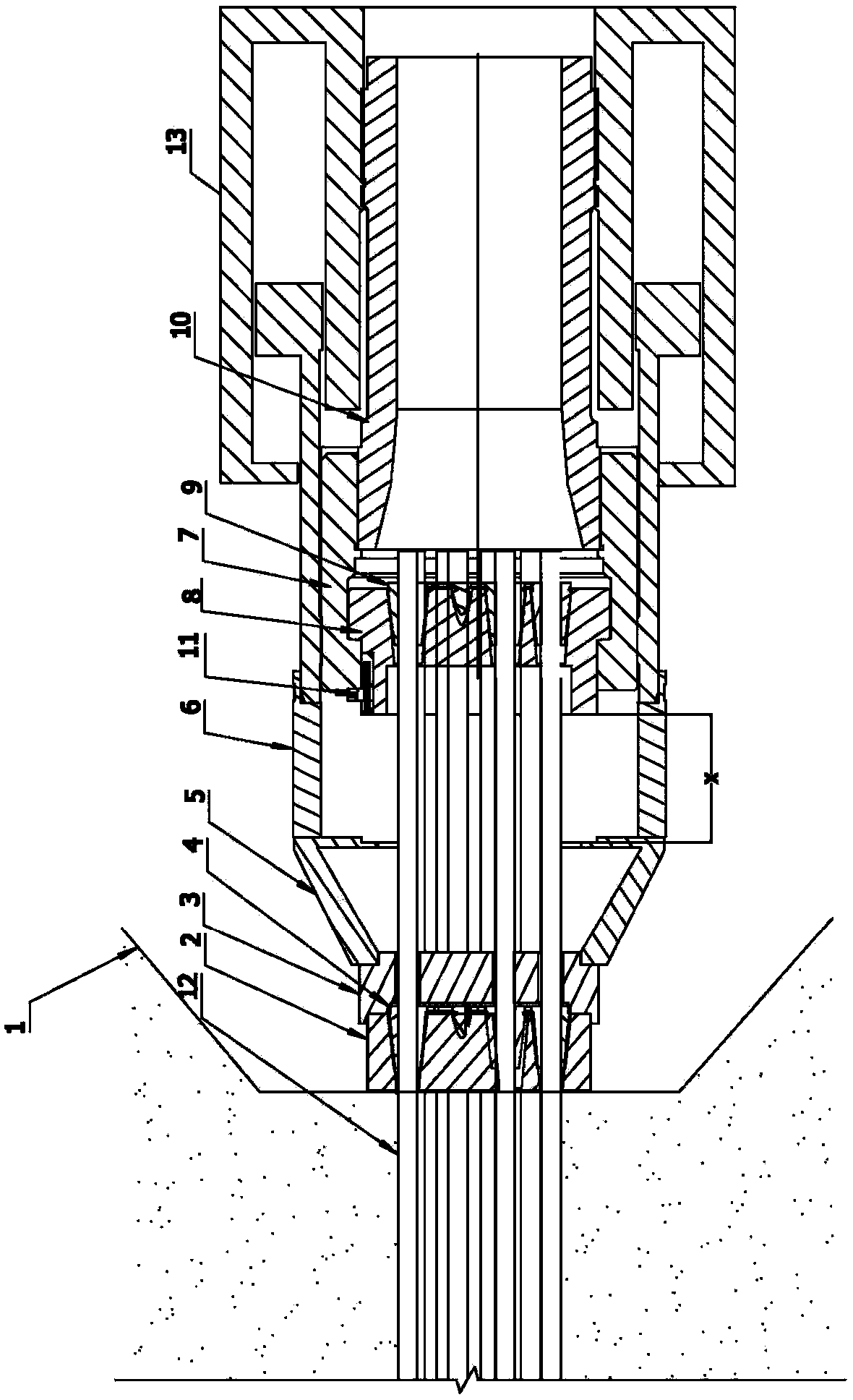

[0052] Such as Figure 2-Figure 6 As shown, the embodiment of the present invention proposes a piercing tensioning cylinder 14 of a bridge ferrule type tensioning system that uses a force sensor to display, measure and control the tension value, including a piston, a hollow force sensor 10, an outer ferrule 7. Inner ferrule tool anchor assembly 8, tool clip 12, wherein the far end of the hollow core force sensor 10 is fixed on the through-heart tension cylinder 14, and the proximal end of the hollow core force sensor 10 is fixed on the outer ferrule 7 and the proximal end of the outer ferrule 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com