Mounting structure for external connector

A mounting structure and connector technology, applied in the electronic field, can solve the problems that the mounting structure is difficult to meet the product design requirements, the internal cables cannot be fixed, and the cable assembly and welding operation is affected, so as to avoid obstacles, improve efficiency, and reduce cables The hidden effect of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

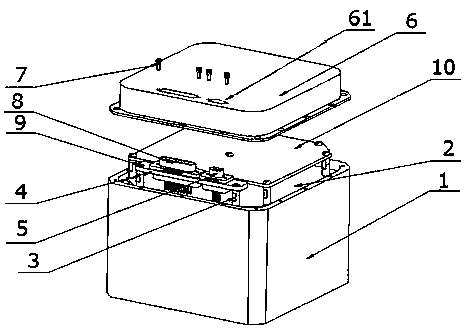

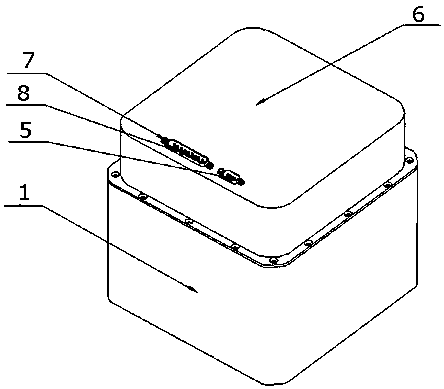

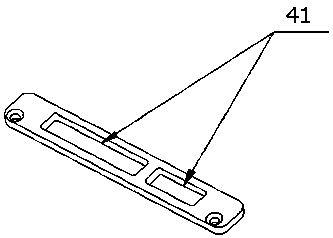

[0017] Such as Figure 1~3 As shown, an installation structure of an external connector includes a base 1 and an upper cover 6 of the product, a first printed board 2 installed on the base, and a support plate arranged between the base 1 and the first printed board 2 4. The support plate 4 is provided with a first through hole 41 for placing the connector, and the upper cover 6 is provided with a second through hole 61 corresponding to the first through hole 41 .

[0018] Through the above setting, the connector can be vertically placed on the support plate 4 through the first through hole 41, so that the cables on the connector can be directly welded downward to the first printed board 2. During the soldering process, The support plate 4 plays the role of fixing the connector and its own cable, preventing the connector from shaking and avoiding the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com