System and method for piston cooling

A piston cooling, piston technology, applied in the direction of piston, liquid cooling, engine cooling, etc., can solve problems such as engine efficiency reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

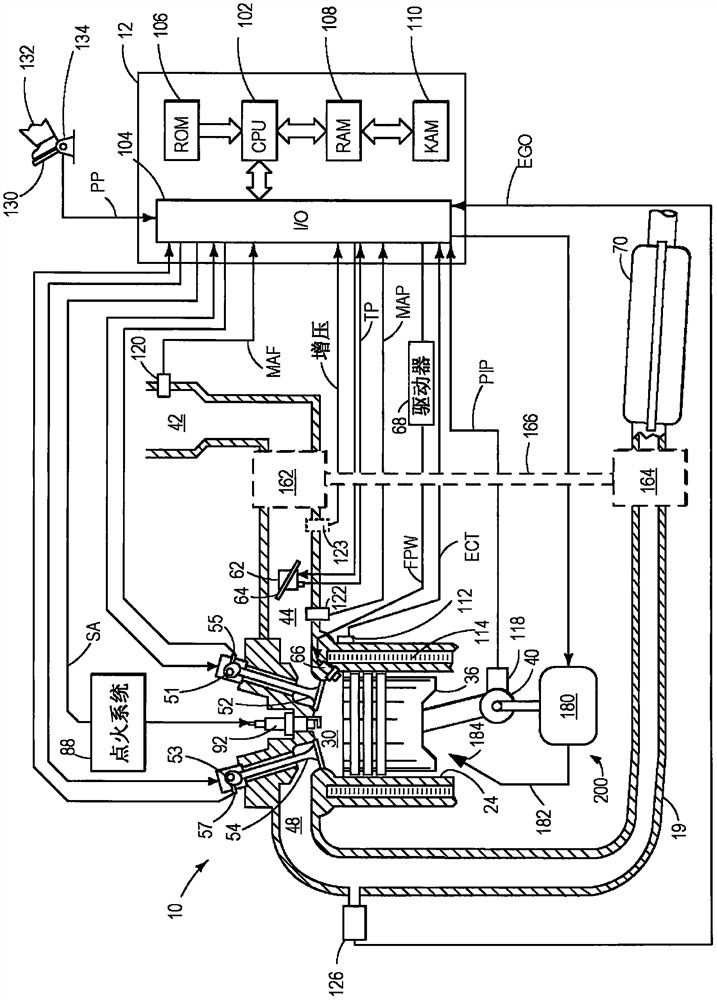

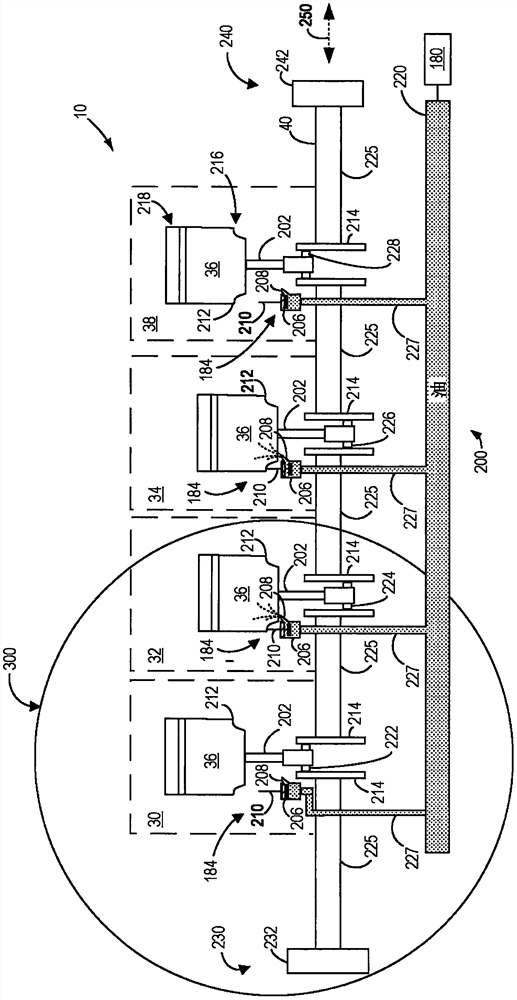

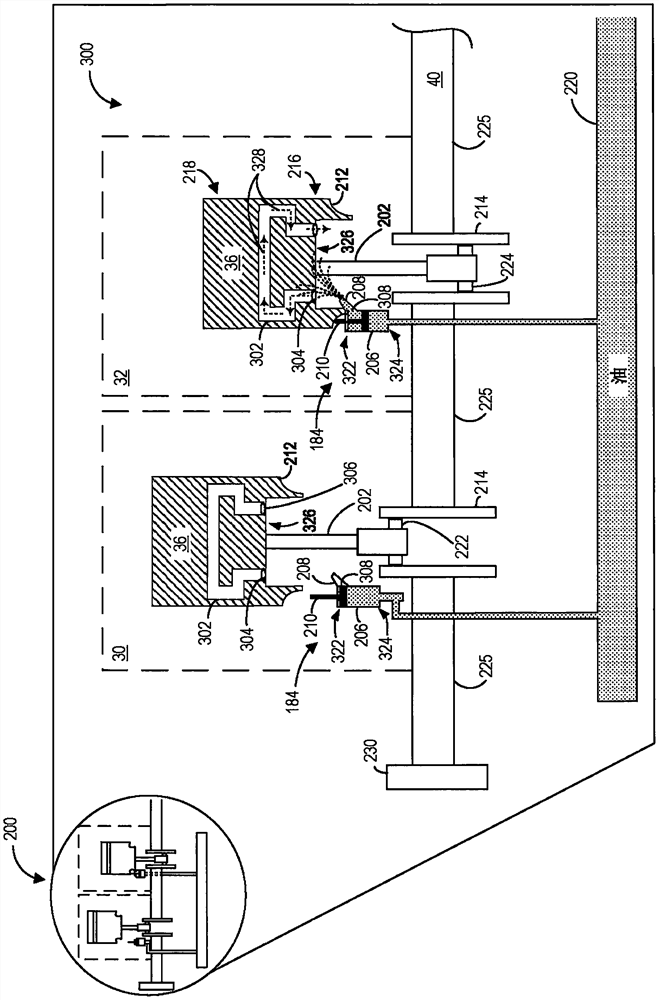

[0016] The following description refers to cooling in the engine (for example, in figure 1 Systems and methods for pistons in the engine shown in ). as in figure 2 As shown in , the engine includes a plurality of pistons and a crankshaft, each piston reciprocating within a cylinder of the engine; and the crankshaft is lubricated and cooled by a lubrication system having an oil pump, oil passages, and a plurality of piston cooling assemblies. Each of the plurality of pistons may receive cooling oil via an associated piston cooling assembly. Such as image 3 As shown, the piston cooling assembly may include a poppet valve, a valve body, and a nozzle. The piston cooling assembly may inject oil onto the associated piston when the associated piston reaches a bottom dead center (BDC) position. Further, the supply may be terminated as the associated piston travels towards top dead center (TDC). Therefore, the oil supply may only be repeatedly activated during a portion of each ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap