Tooth-shaped chain for high-speed transmission of novel meshing mechanism

A high-speed transmission and toothed chain technology, applied in the field of chain transmission, can solve the problems of high-end hosts with high precision and low noise, and achieve the effects of reducing polygonal effects, improving ride comfort, and meeting high-quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

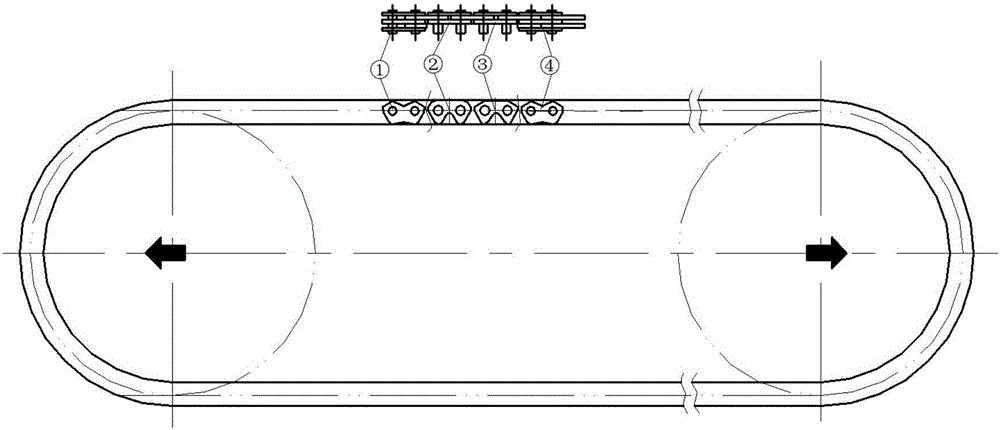

[0018] The toothed chain for high-speed transmission of the new meshing mechanism provided by the present invention will be described in detail below in conjunction with an implementation case.

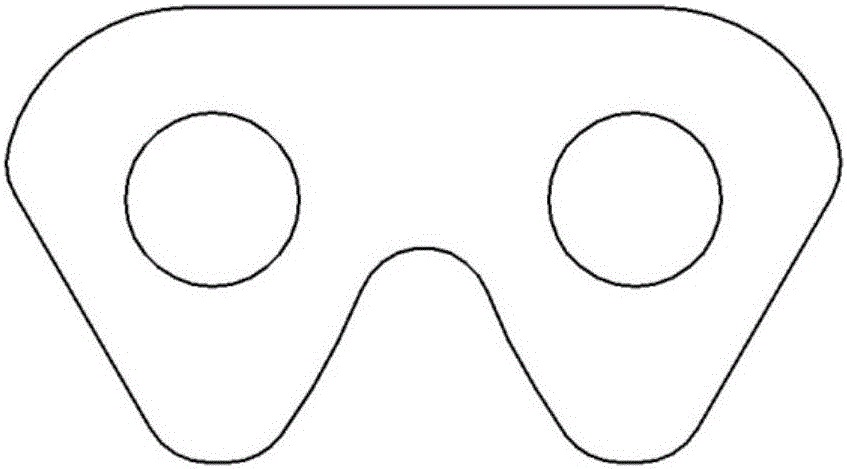

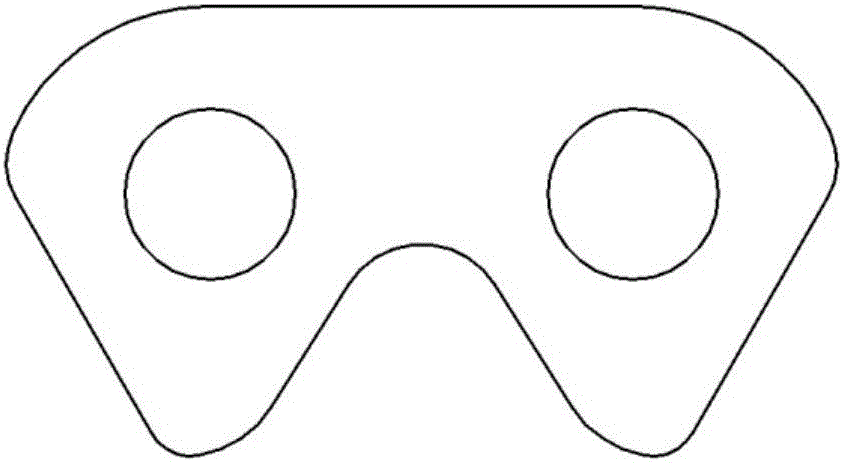

[0019] This embodiment is a toothed chain for transmission of an automobile gearbox, which includes a pin shaft ①, an inner-outer compound meshing chain plate ②, an outer meshing chain plate ③, and a guide plate ④. The outer tooth profiles of the inner-outer compound meshing chain plate ② and the outer meshing chain plate ③ (no 2 and 3 in the figure) are straight lines, the inner tooth profile of the inner-outer compound meshing chain plate ② is a circular arc, and the outer toothing chain The outer tooth profile of plate ③ is a straight line. The toothed chain for transmission of the automobile gearbox includes several groups of inner-outer composite meshing chain plates ② and several groups of outer meshing chain plates ③.

[0020] In this embodiment, the pitch of the toothed chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com