Decorative cover mounting structure of range hood

A technology of a range hood and an installation structure, which is applied in the field of range hoods, can solve the problems of cracking of tiles, troublesome installation, inability to install a decorative cover, etc., and achieves the effects of low installation cost and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

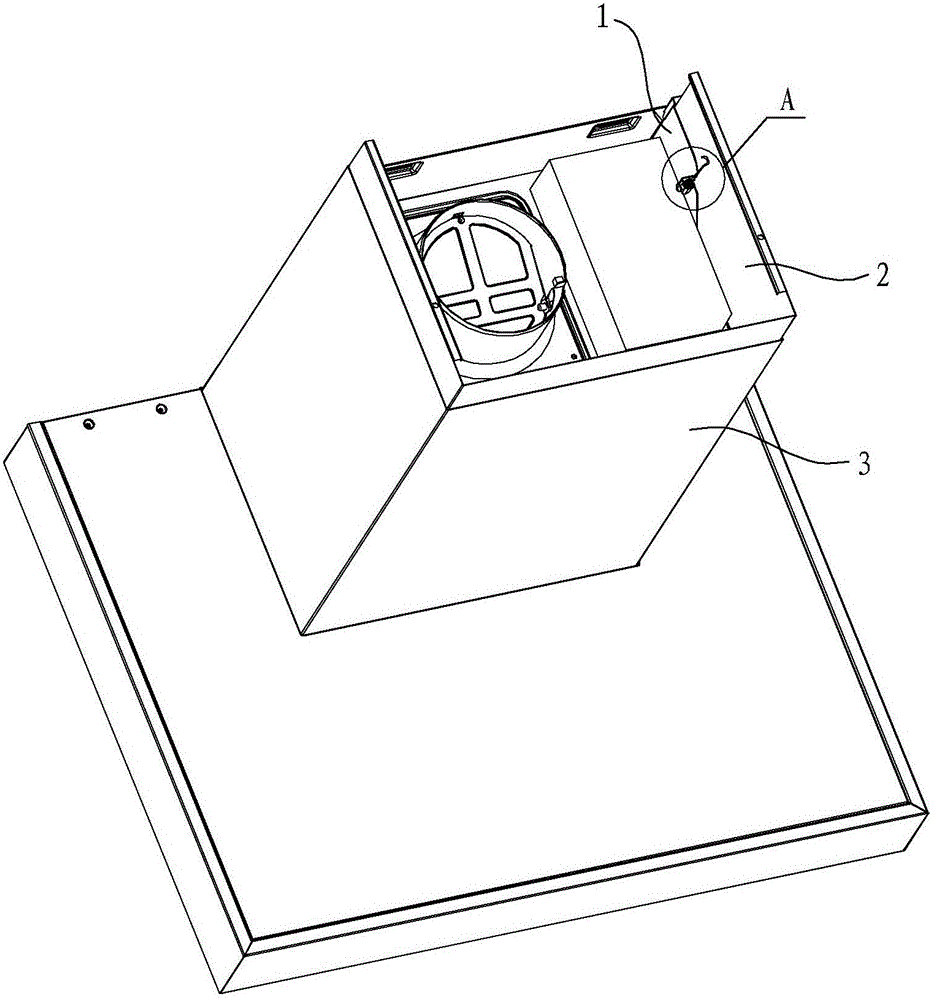

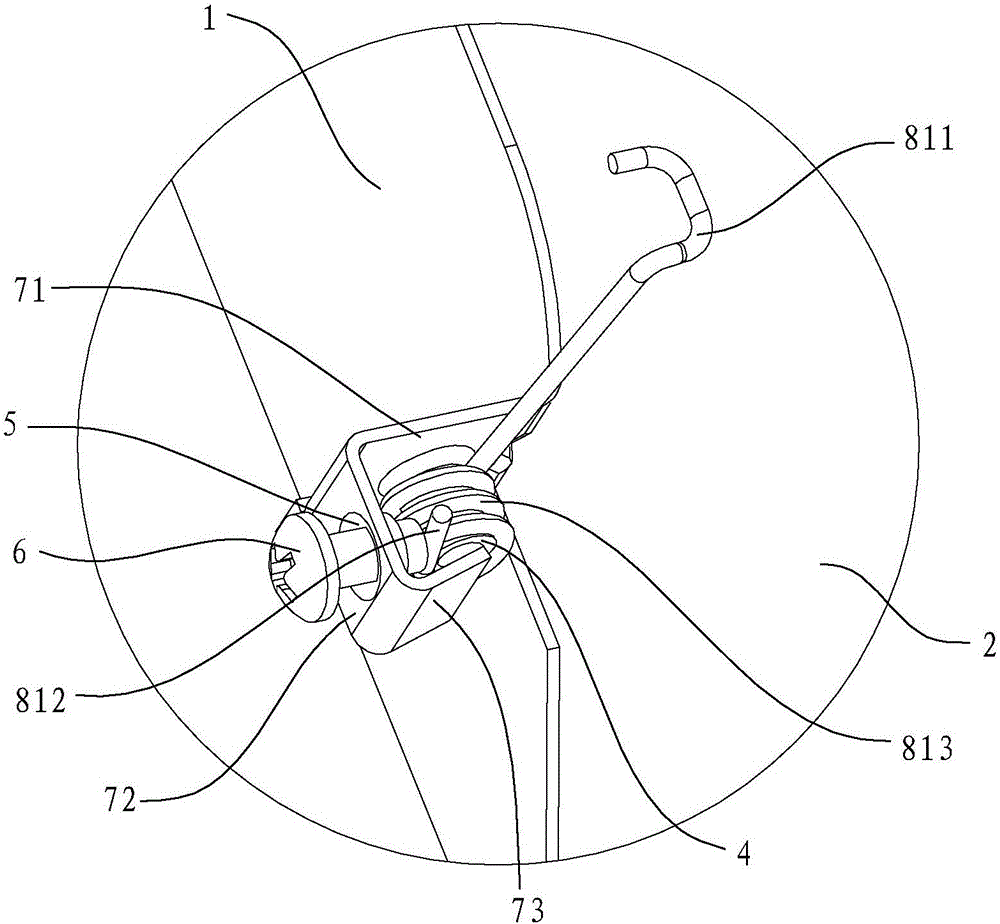

[0028] Such as Figure 1 to Figure 4 As shown, the decorative cover installation structure of the range hood in this embodiment includes a fan frame 1 and a decorative cover 2, the fan frame 1 is fixed inside the fan cover 3, and the decorative cover 2 is limited between the fan cover 3 and the fan cover. In the interlayer between the frames 1 and can move up and down relative to the fan cover 3, the outer wall of the decorative cover 2 is offset against the inner wall of the fan cover 3, that is, the fan cover 3 constitutes a limit plate that prevents the decorative cover 2 from moving to the outside. A torsion spring installation bracket is formed on the left and right side walls of the fan frame 1, and a torsion spring and a torsion adjustment member are installed on the torsion spring installation bracket. The torque regulating member can directly act on the second force application end of the torsion spring, and further adjust the pressing force of the first force applica...

Embodiment 2

[0034] Such as Figure 5 to Figure 8 As shown, the torsion spring mounting bracket in this embodiment is formed with two installation shafts 4 arranged sequentially along the folding direction of the first flange 71 on the first flange 71, and the second torsion spring 82 includes two mounting shafts. The winding unit 823 on the corresponding installation shaft 4 , the outer ends of the two winding units 823 respectively form the first force application end 821 and the second force application end 822 of the second torsion spring. The rest of the structure in this embodiment is the same as that in Embodiment 1, and will not be further described here.

Embodiment 3

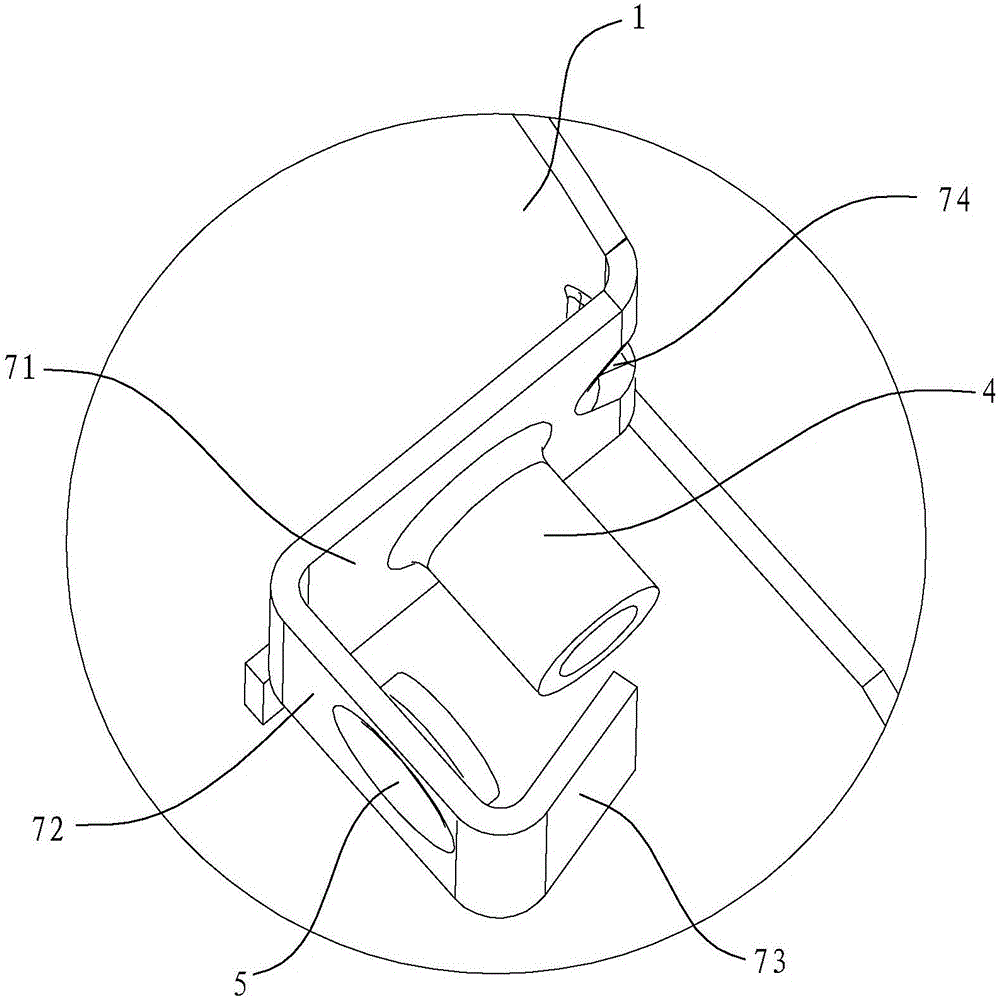

[0036] Such as Figure 9 to Figure 12As shown, the torsion spring mounting bracket in this embodiment includes a first bent piece 91 and a second bent piece 92 that are perpendicular to each other. Both the left side wall and the right side wall of the fan frame 1 are bent inward to form a first bent piece 91, and one side of the first bent piece 91 is provided with a mounting shaft 4, and a threaded inner hole is provided on the mounting shaft 4 , the other side of the first bending piece 91 is provided with a limit screw 10, and the limit screw 10 can be screwed into the threaded inner hole of the installation shaft 4. A mounting hole 5 is opened on the second bending piece 92 . The torsion spring in this embodiment is the third torsion spring 83, which includes two winding units 833 respectively installed on the installation shaft 4 and the limit screw 10, the outer ends of the two winding units 833 A first force application end 831 of the third torsion spring is formed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com