Method for detection of machining deviation of crtsⅢ track plate

A deviation detection, track plate technology, applied in the direction of measuring devices, geometric CAD, instruments, etc., can solve the problem of inability to realize the refined three-dimensional reconstruction of the surface model of the track plate, the detection of the processing deviation of the track plate, and the skew value of the embedded casing Unable to detect and other problems to achieve the effect of reducing omissions, avoiding arbitrariness, and reducing personnel investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

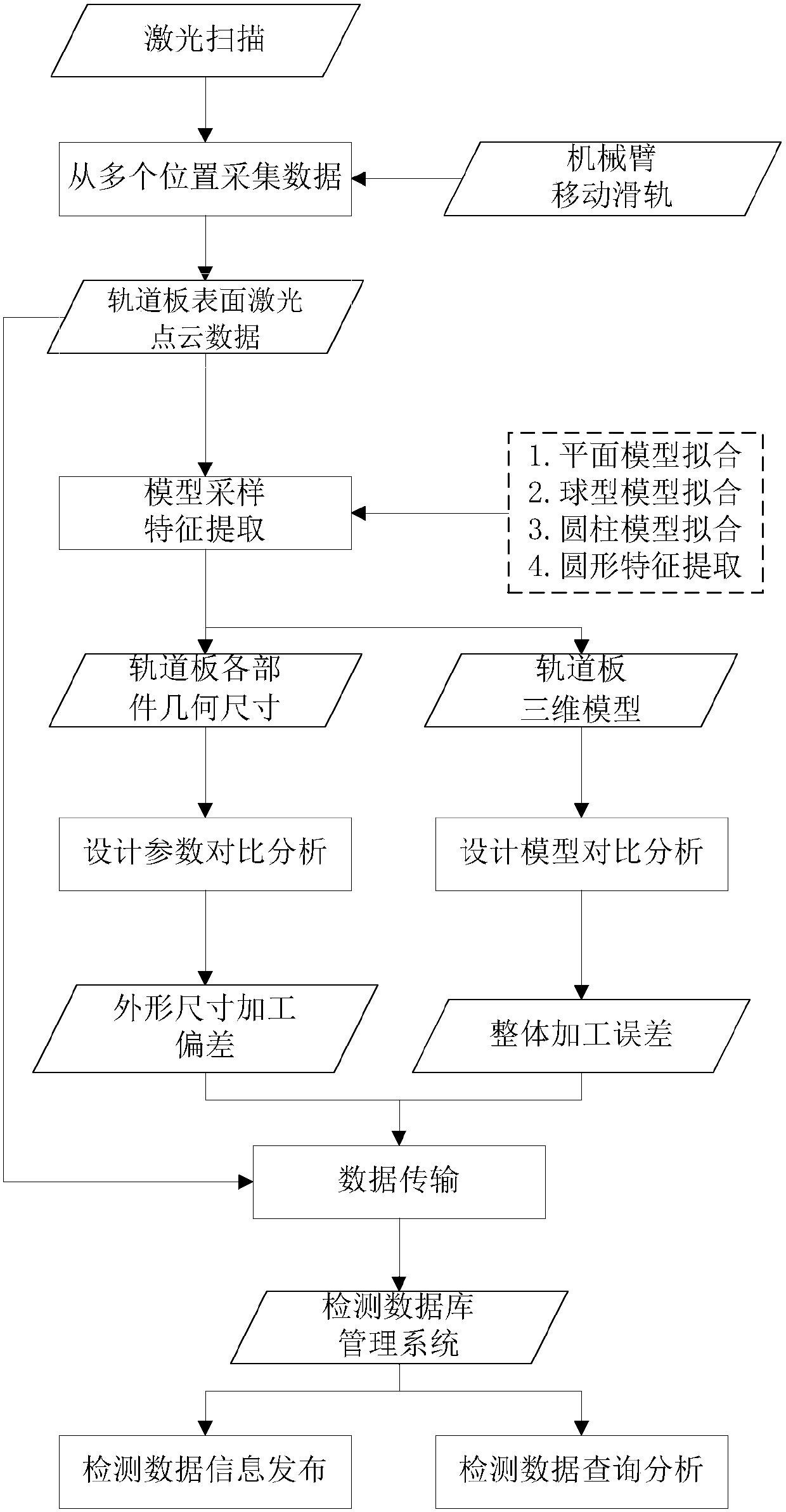

[0038] The detection method of the present invention will be described in detail below with reference to the accompanying drawings.

[0039] like figure 1 As shown, the method for detecting the deviation of the outer dimension of the CRTS III track plate of the present invention comprises the following steps:

[0040] A CRTS III type track plate processing deviation detection method, comprising the following steps:

[0041] S1. Use a robotic arm and / or a mechanical slide, and a laser scanning system to scan the track plate from multiple positions, and correct the data collected from multiple positions into laser point cloud data on the track plate surface in a unified coordinate system ;

[0042] S2, using the model random sampling consistency algorithm to automatically extract the model of each component of the track plate from the laser point cloud data, and obtain the geometric dimensions of each component of the track plate;

[0043] S3. Compare the obtained geometric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com