A high-performance asymmetric metal oxide-based micro-supercapacitor and its preparation method

A supercapacitor, oxide-based technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor matching of positive and negative electrode materials, low coulombic efficiency of devices, and low electrode utilization , to achieve the effect of enhancing pseudocapacitive capacity, improving Coulombic efficiency benefits, and increasing energy and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

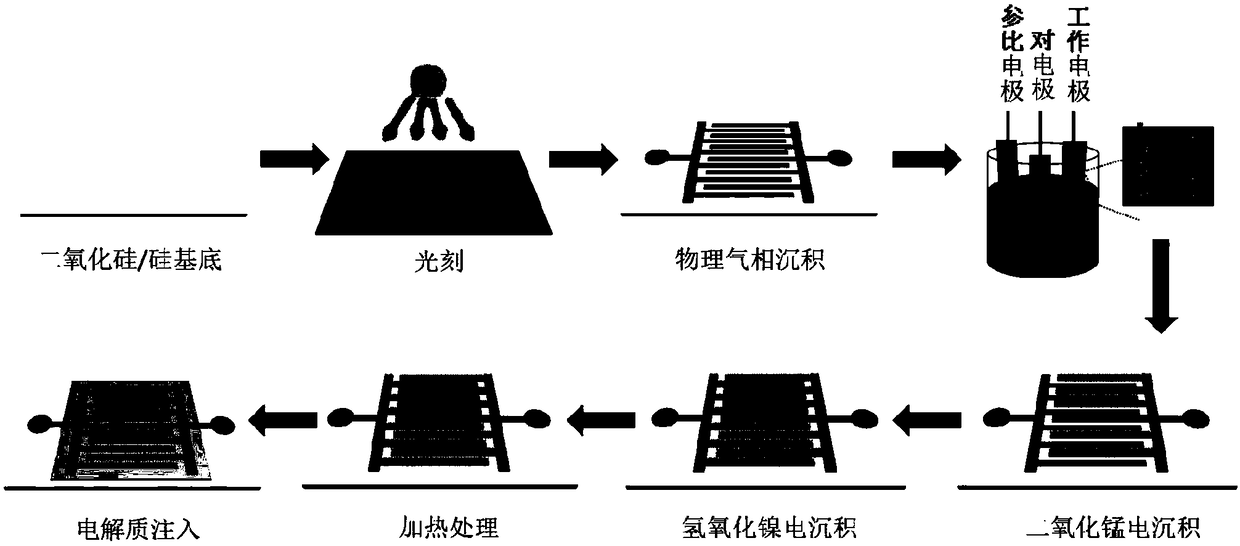

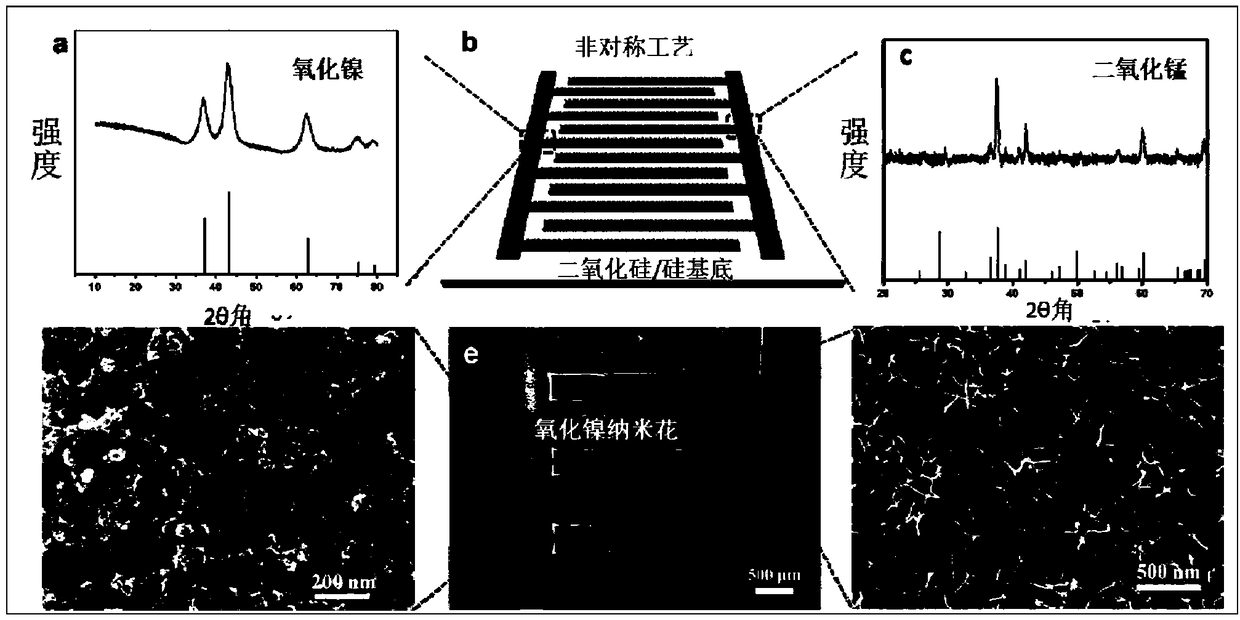

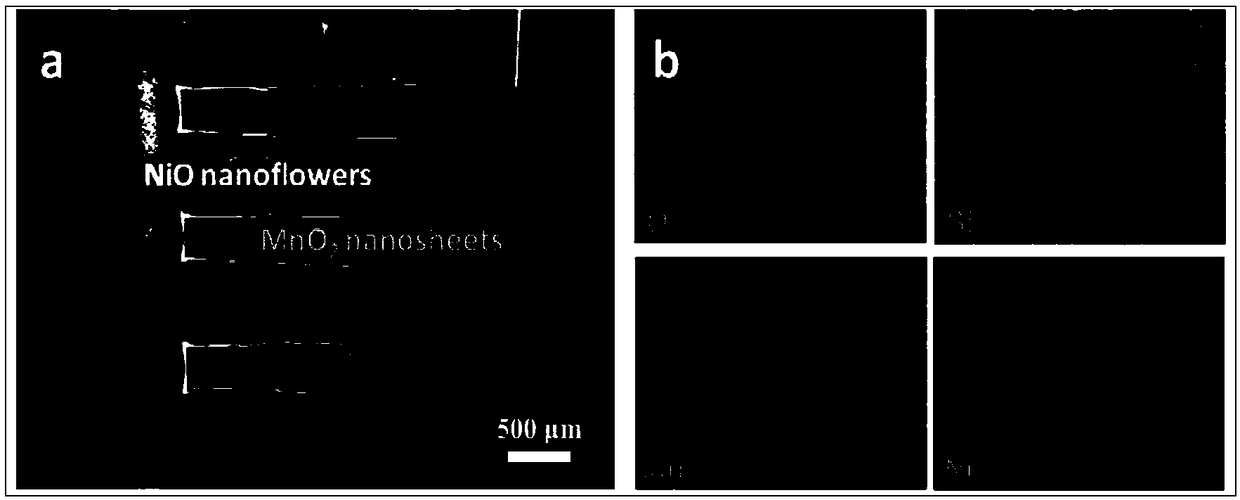

[0027] It has a high-performance asymmetric metal oxide-based micro-supercapacitor, which includes the following steps:

[0028] 1) Coat the photoresist 9000A on the silicon wafer substrate with a coater at a speed of 4000rpm, spin coating for 40s, and then bake the glue with a hot plate at 100°C for 15min;

[0029] 2) Fabricate an interdigitated structure with a width of 100 microns by photolithography;

[0030] 3) Physical Vapor Deposition (PVD): Use a thermal evaporation coater to vaporize the metal electrode Cr / Ni (10nm / 100nm);

[0031] 4) After heating the acetone to 50°C and keeping it warm for 15 minutes, put the device in it and let it stand for 1 hour to peel off all the interfingers, then rinse the substrate with acetone and isopropanol, and dry it with nitrogen;

[0032] 5) Apply silver paste to the positive and negative poles of the current collector respectively, be careful not to connect them, and let them stand for 6 hours at room temperature and ventilation; ...

Embodiment 2

[0039] It has a high-performance asymmetric metal oxide-based micro-supercapacitor, which includes the following steps:

[0040] 1) Coat the photoresist 9000A on the silicon wafer substrate with a coater at a speed of 4000rpm, spin coating for 40s, and then bake the glue with a hot plate at 100°C for 15min;

[0041] 2) Fabricate an interdigitated structure with a width of 100 microns by photolithography;

[0042] 3) Physical Vapor Deposition (PVD): Use a thermal evaporation coater to vaporize the metal electrode Cr / Ni (10nm / 100nm);

[0043] 4) After heating the acetone to 50°C and keeping it warm for 15 minutes, put the device in it and let it stand for 1 hour to peel off all the interfingers, then rinse the substrate with acetone and isopropanol, and dry it with nitrogen;

[0044] 5) Apply silver paste to the positive and negative poles of the current collector respectively, be careful not to connect them, and let them stand for 6 hours at room temperature and ventilation; ...

Embodiment 3

[0051] It has a high-performance asymmetric metal oxide-based micro-supercapacitor, which includes the following steps:

[0052] 1) Coat the photoresist 9000A on the silicon wafer substrate with a coater at a speed of 4000rpm, spin coating for 40s, and then bake the glue with a hot plate at 100°C for 15min;

[0053] 2) Fabricate an interdigitated structure with a width of 100 microns by photolithography;

[0054] 3) Physical Vapor Deposition (PVD): Use a thermal evaporation coater to vaporize the metal electrode Cr / Ni (10nm / 100nm);

[0055] 4) After heating the acetone to 50°C and keeping it warm for 15 minutes, put the device in it and let it stand for 1 hour to peel off all the interfingers, then rinse the substrate with acetone and isopropanol, and dry it with nitrogen;

[0056] 5) Apply silver paste to the positive and negative poles of the current collector respectively, be careful not to connect them, and let them stand for 6 hours at room temperature and ventilation; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com