A battery heating device with thermal management

A battery heating and heating technology, used in secondary batteries, circuits, electrical components, etc., can solve the problems of uneven heating, complex process, high cost, and achieve fast heating speed, uniform heat source distribution, and strong anti-vibration performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

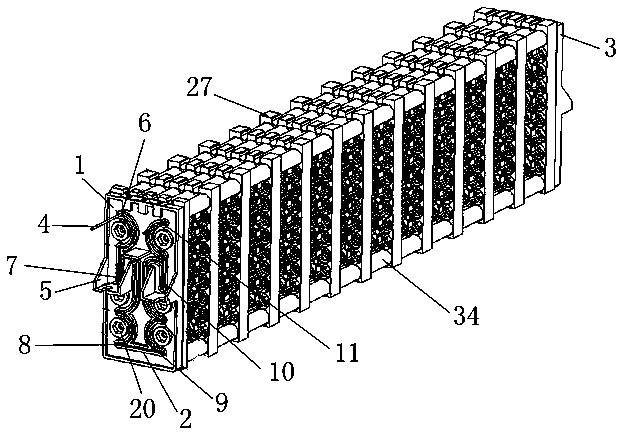

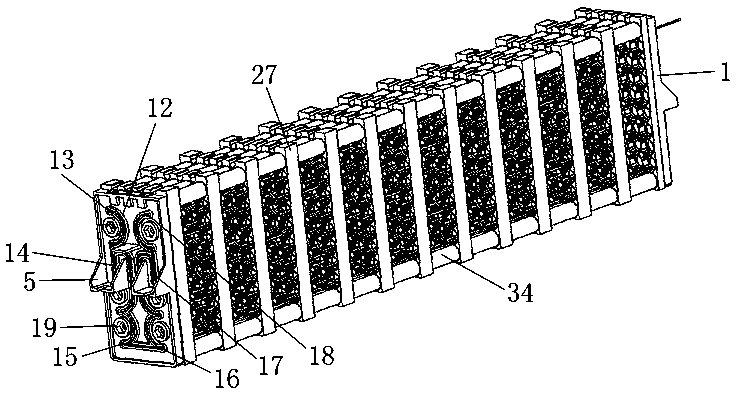

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

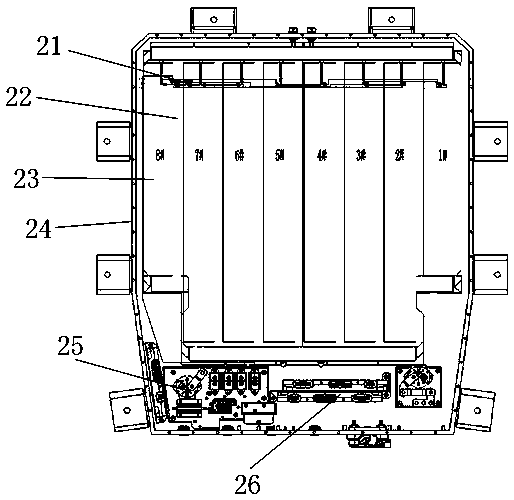

[0032] The present invention includes a box body 24, which is provided with a voltage temperature acquisition device 22, a battery heating device 23, and a battery management system. The battery heating device 23 includes a first pressing plate 1, a second pressing plate 3, and a battery connection device. The battery connection device Including a double-sided integral fixture 27, the double-sided integral fixture 27 is provided with a first through hole, and the first through holes are arranged in a matrix on the double-sided integral fixture 27, and a partition 29 is arranged in the first through hole, and the partition 29 The first through hole is divided into a positive pole hole 28 and a negative pole hole 30. The negative pole hole 30 is provided with a shrapnel groove, and the shrapnel groove is provided with an elastic conductive sheet 31. The shrapnel groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com