Spoke wheel rim

A spoked wheel and spoke technology, applied to spoked wheels, rims, wheels, etc., can solve problems such as expensive, uneconomical, and easy to break, and achieve the effects of improving maneuverability, reducing weight, and reducing rolling friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

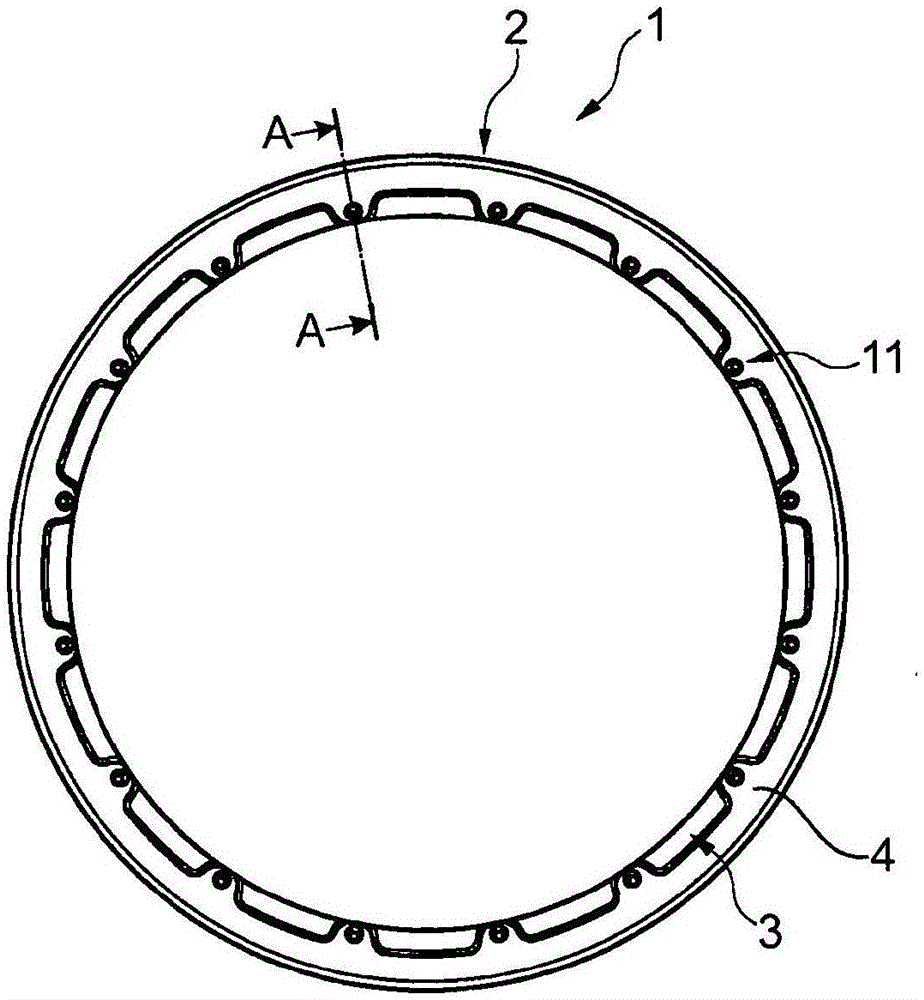

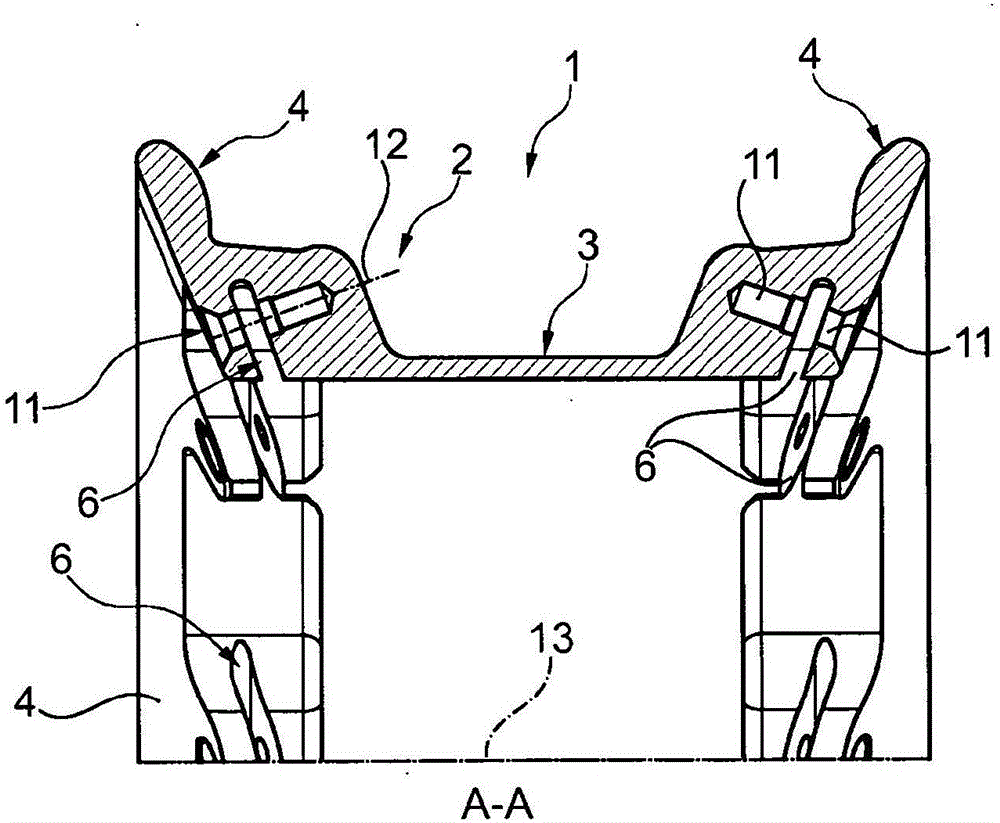

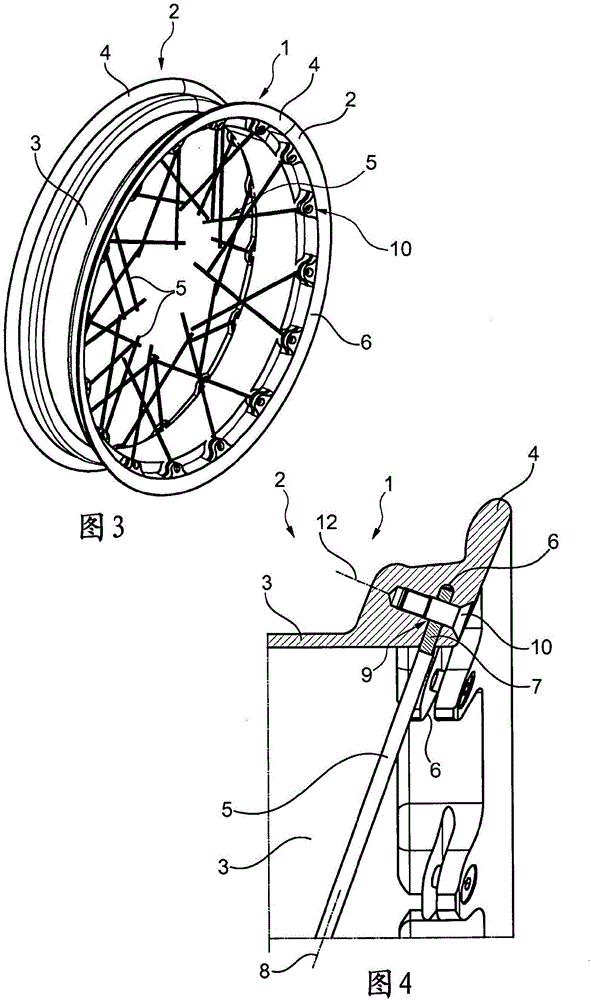

[0024] corresponds to Figures 1 to 4 A spoked rim 1 according to the invention for a tubeless tire (not shown) has a rim lock ring 2 with a rim foot 3 and two rim edges 4 . The rim locking ring 2 is here connected via spokes 5 to a not shown hub. According to the invention, grooves 6 extending in the circumferential direction are now provided on the rim lock ring 2, into which grooves the spokes 5 engage with their respective longitudinal ends with spoke heads 7 (see especially Figure 4 ). The spoke head 7 has a through hole 9 formed transversely to the spoke axis 8 (especially with reference to Figure 5 ), said through hole is aligned with the screw-in opening 11 in the rim lock ring 2 in the assembled position of the spoke 5 . The screw-in opening 11 has an internal thread. On each slot 6 there is provided a screw 10 traversing said slot and screwable from the outside. Screw 10 here with its external thread 14 (especially with reference to Image 6 ) is screwed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com