Electronic control module and method for producing the same

A technology of electronic control modules and electronic circuits, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, providing connectors and printed circuit boards, etc., can solve the problems of not being able to achieve airtightness, and achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

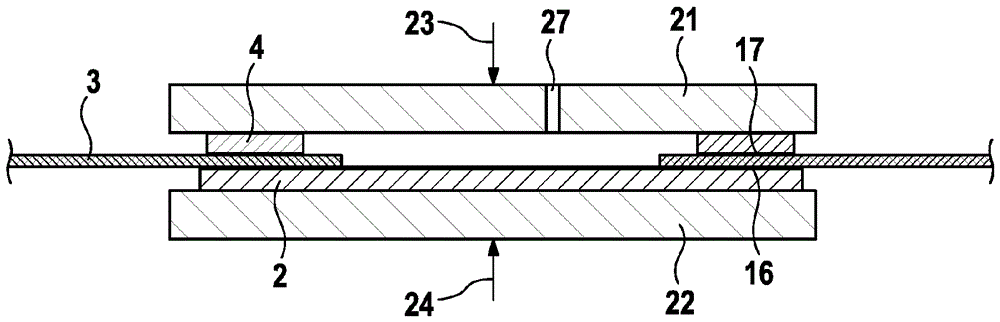

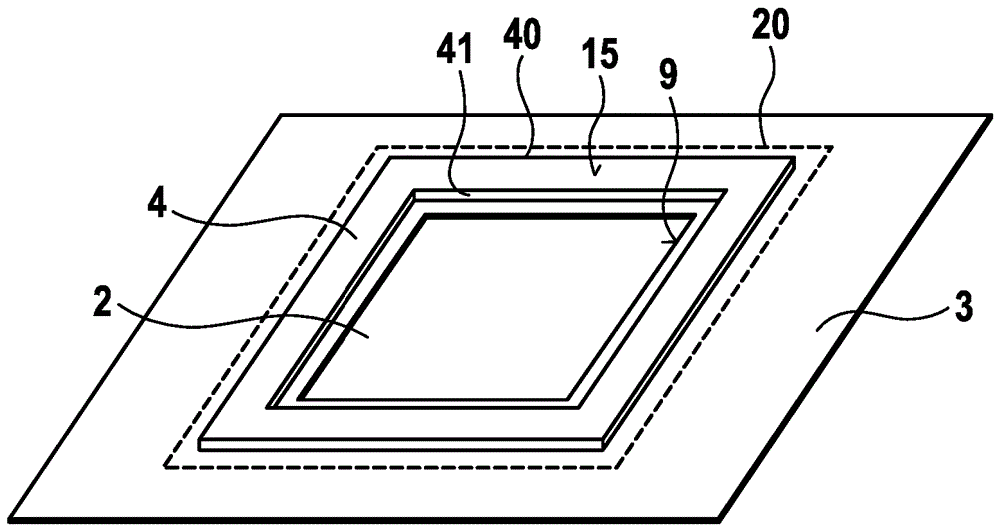

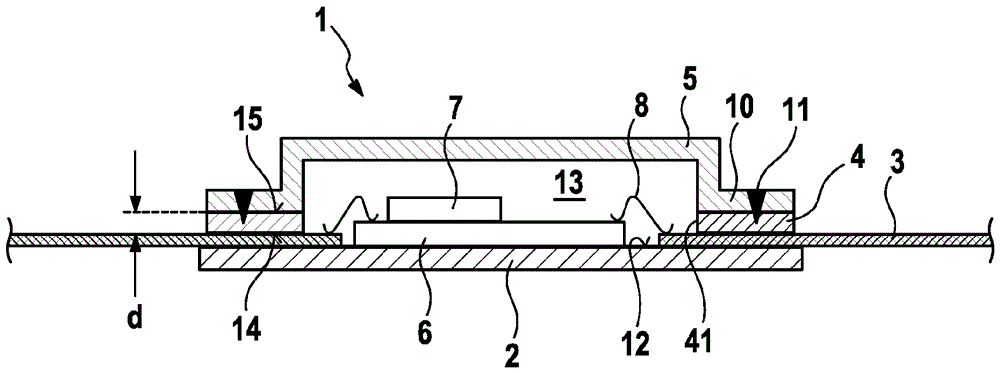

[0022] figure 1 A cross-section through an electronic control module according to the invention is shown schematically, as it can be embodied, in particular, on or in a motor vehicle transmission. The electronic control module 1 is designed in such a way that it can withstand transmission oil. The electronic control module 1 in this exemplary embodiment has, for example, a carrier plate 2 . The carrier plate 2 can consist, for example, of metal and preferably of aluminum. For example, a flexible circuit board 3 is applied to the carrier plate 2 . For this, if Figure 4 and Figure 5 As shown in , an adhesive film 16 can be applied to the upper side of the carrier plate 2 and the flexible circuit board 3 is laminated to the carrier plate 2 via the adhesive film 16 . The flexible circuit board 3 has cutouts 9, such as figure 2 shown in . The upper side of the carrier plate, which is coated with the adhesive film 16 , is exposed through the cutout 9 . The electronic circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com