Flax no-tillage seeding equipment and seeding method thereof

A technology of no-tillage seeding and flax, applied in botanical equipment and methods, shovels, plows, etc., can solve the problems of soil surface structure damage, affecting the effect of no-tillage, lack of broken soil in sowing trenches, etc. The effect of saving seed input, increasing yield and planting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

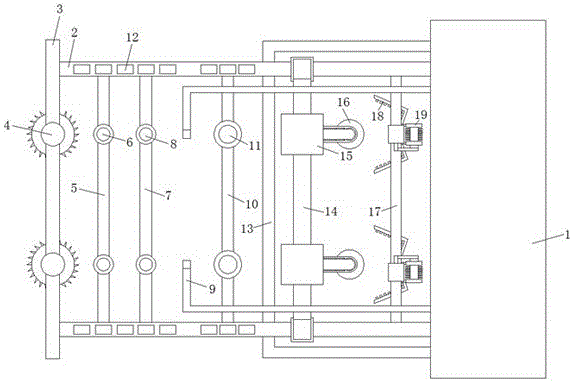

[0020] refer to figure 1 , the present embodiment proposes a flax no-till planting equipment, including power equipment 1, two support columns 2 are provided on one side of the power equipment 1, and a connecting column 3 is provided at the end of the support column 2 away from the power equipment 1, The two support columns 2 are connected by the connecting column 3, and the side of the connecting column 3 close to the power equipment 1 is successively provided with the first connecting rod 5, the second connecting rod 7, the third connecting rod 10, the seed pipe 13, and the third connecting rod 14 and the fourth connecting rod 17, and the two ends of the first connecting rod 5, the second connecting rod 7, the third connecting rod 10, the seeding pipe 13, the third connecting rod 14 and the fourth connecting rod 17 are all fixed on two On a supporting column 2, the first connecting rod 5, the second connecting rod 7, the third connecting rod 10, the seed pipe 13, the third c...

Embodiment 2

[0026] refer to figure 1 , the present embodiment proposes a flax no-till planting equipment, including power equipment 1, two support columns 2 are provided on one side of the power equipment 1, and a connecting column 3 is provided at the end of the support column 2 away from the power equipment 1, The two support columns 2 are connected by the connecting column 3, and the side of the connecting column 3 close to the power equipment 1 is successively provided with the first connecting rod 5, the second connecting rod 7, the third connecting rod 10, the seed pipe 13, and the third connecting rod 14 and the fourth connecting rod 17, and the two ends of the first connecting rod 5, the second connecting rod 7, the third connecting rod 10, the seeding pipe 13, the third connecting rod 14 and the fourth connecting rod 17 are all fixed on two On a supporting column 2, the first connecting rod 5, the second connecting rod 7, the third connecting rod 10, the seed pipe 13, the third c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com