A two-fluid spray gun

A two-fluid spray and spray gun technology, applied in the direction of liquid injection devices, spray devices, etc., can solve the problems of poor fogging performance, large water consumption, easy to block nozzle holes, etc., achieve improved fogging performance, save energy, and overcome water consumption big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

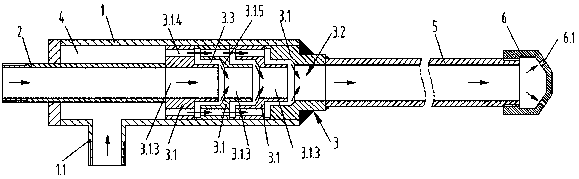

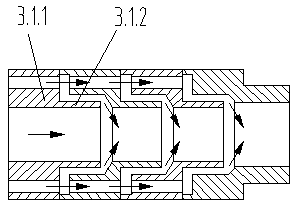

[0025] Embodiment 1: A two-fluid spray gun, comprising a cylindrical gun body 1, a liquid inlet pipe 2 arranged coaxially with the end of the gun body 1, arranged on the side wall of the cylindrical gun body 1 and communicated with the inner cavity of the cylindrical gun body 1 The air inlet pipe 1.1 of the cylindrical gun body 1 is sealed with a gas-liquid mixing joint 3 at one end of the cavity. The gas-liquid mixing joint 3 is formed by four T-shaped sleeves 3.1 which are sequentially set and sealed. The T-shaped sleeve 3.1 includes a small diameter Section 3.1.1 and large-diameter section 3.1.2, the large-diameter section 3.1.2 of the adjacent T-shaped sleeve 3.1 is socketed on the small-diameter section 3.1.1, and the central through-hole 3.1.3 of the four T-shaped sleeves 3.1 is connected to each other to form a The central mixing channel 3.2, the first T-shaped sleeve 3.1 central through hole 3.1.3 closest to the liquid inlet pipe 2 is connected to the liquid inlet pipe ...

Embodiment 2

[0026]Embodiment 2: Referring to Embodiment 1, the gas-liquid mixing joint 3 includes a base body, a central mixing channel 3.2 in the center of the base body, and the small-diameter section 3.4 of the base body extends into the cylindrical gun body 1 and is connected with the liquid inlet pipe 2. The diameter of the small-diameter section 3.4 is smaller than that of the barrel The inner diameter of the gun body is 1, and the side wall of the small diameter section 3.4 is provided with 3 dry groups of air inlet holes 3.3 inclined towards the axis of the central mixing channel 3.2. The middle section of the central mixing channel 3.2 is set as the small diameter closing section 3.2.1.

Embodiment 3

[0027] Embodiment 3: Referring to Embodiment 2, the side wall of the small-diameter section 3.4 is provided with several rectangular through grooves 3.5 around the center of the circle.

[0028] The gas-liquid mixing sleeve 7 can be added at the connection between the spray gun head 6 and the long gas-liquid mixing tube 5 in the above-mentioned embodiments 1-3, and the spiral guide body 8 is arranged inside the gas-liquid mixing sleeve 7 .

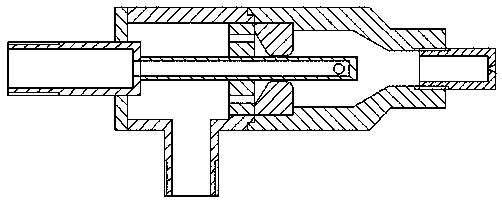

[0029] The gas-liquid mixing long tube 5 is actually an oblong channel, which is a cavity for the gas-liquid to roll, rotate and impact the flow in the cavity, which is different from the original technology ( figure 1 ) ratio, the length of the mixing chamber has increased a lot, from the original 40~50mm to 500~800mm. The purpose of the increase of the gas-liquid mixing chamber is to allow enough time and space for gas and liquid to mix in the chamber to improve the mixing effect. The basis for determining the length of the mixing chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com