Tin powder screening device

A sieving device and tin powder technology, which is applied in the direction of sieving, solid separation, and separation of solids from solids with airflow, can solve the problems of low screening efficiency and failure to meet expected requirements, and achieve improved screening Separation efficiency, the effect of increasing the number of screening layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein.

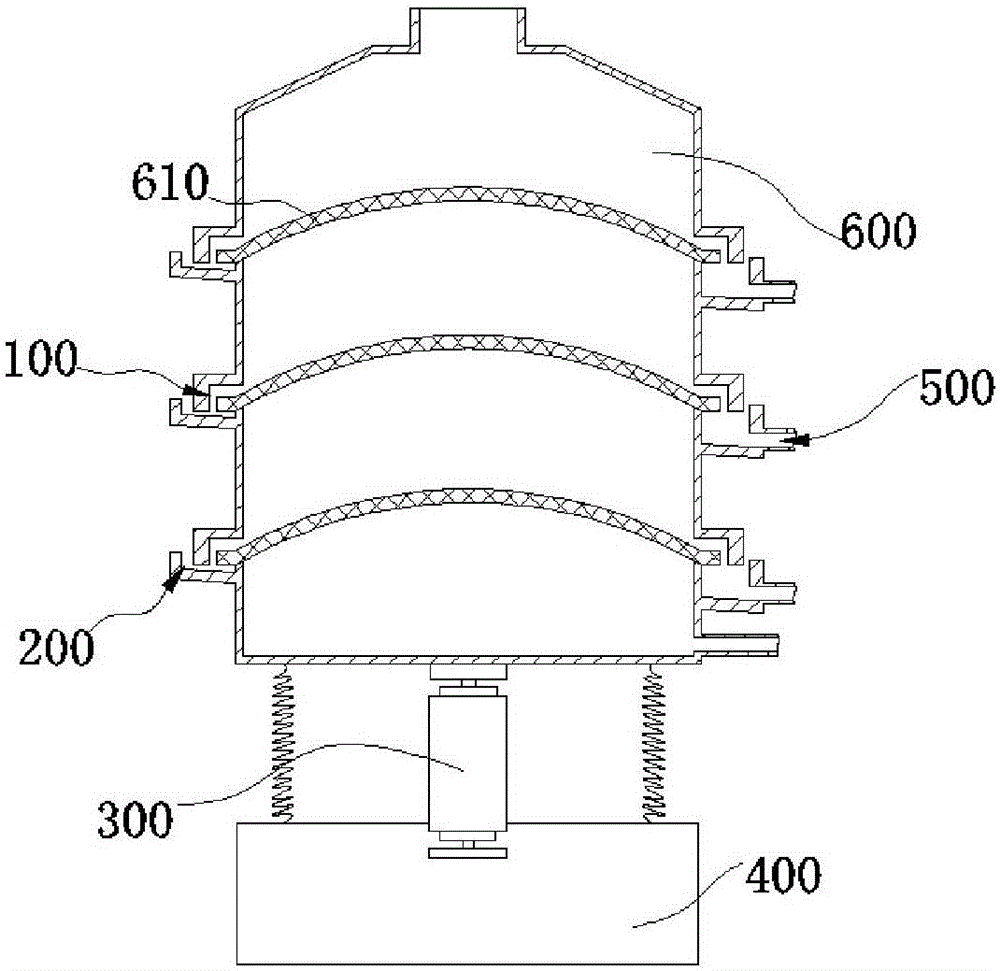

[0011] as attached figure 1 As shown, a tin powder screening device includes a base 400, a vibration motor 300 and several screening layers 600 of different meshes. The bottom of the screening layer 600 is provided with a screening net 610, and the vibration motor 300 is located on the base 400 and Between the sieving layers 600, the middle part of the sieving net 610 protrudes slightly upwards, and a plurality of leakage holes 100 are provided at the edges of the surrounding sides of the sieving net 610; , The receiving tank 200 is provided with a discharge port 500 .

[0012] In a preferred manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com