Automatic basket cleaning all-in-one machine

An all-in-one machine and basket technology, applied in chemistry, dryers, object stacking, etc., can solve problems such as environmental pollution of the cleaning site, inadequate cleaning of plastic baskets, and injury to cleaning personnel, etc., to reduce pollution and fully Azimuth efficient cleaning and disinfection, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below with reference to the accompanying drawings.

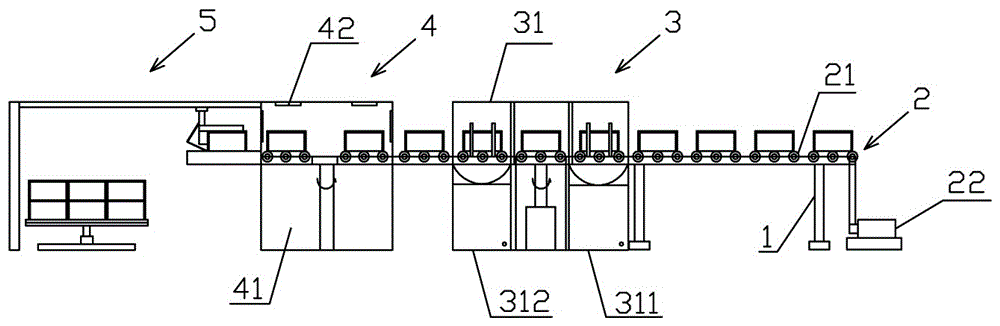

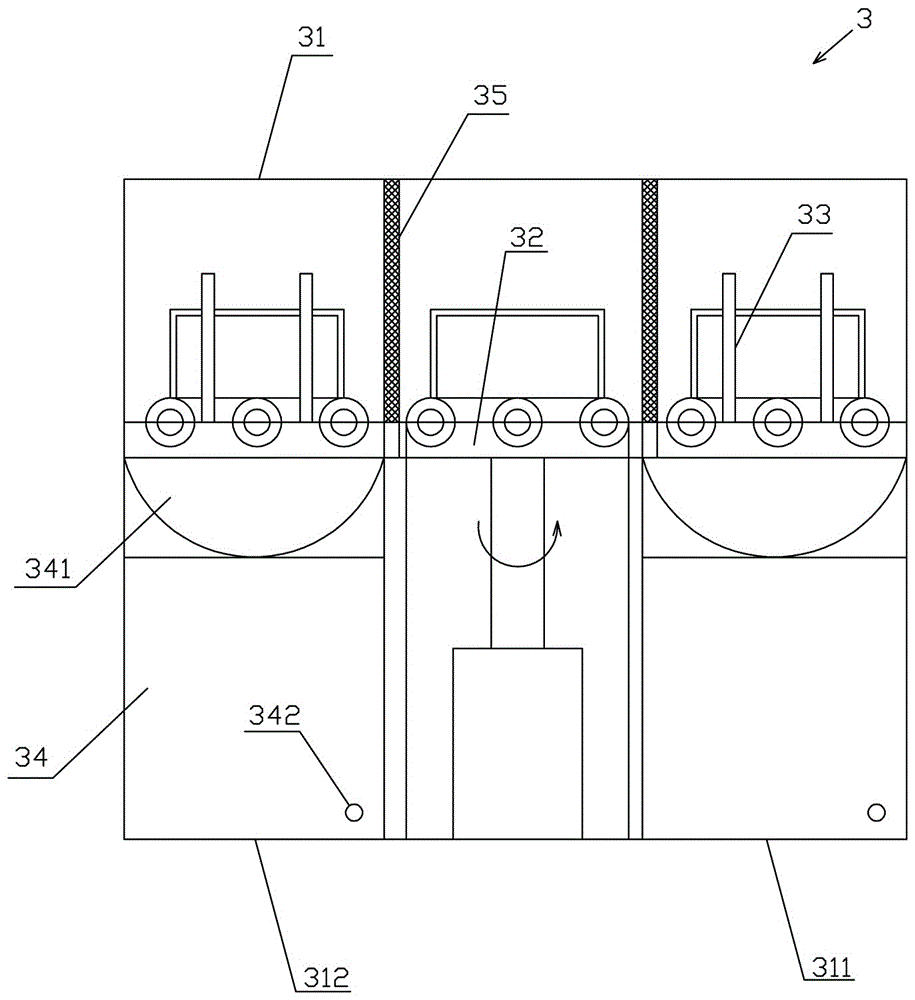

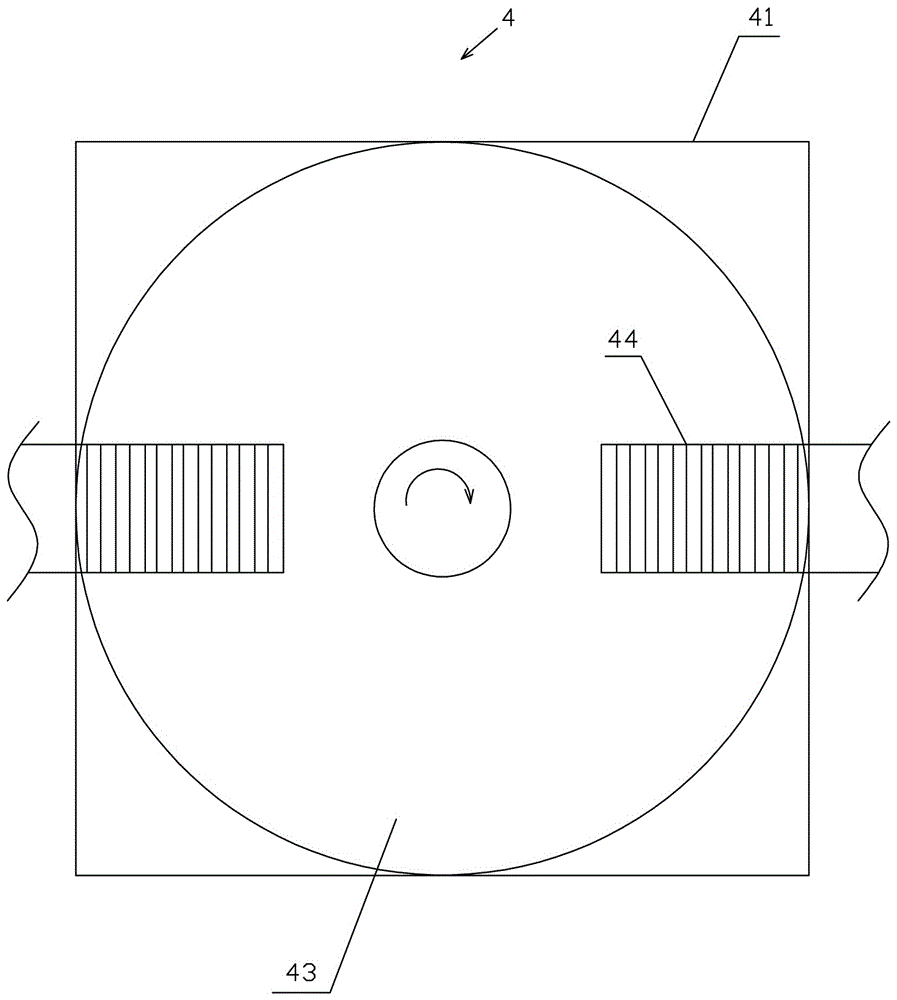

[0026] Such as figure 1 , figure 2 and image 3 As shown, an automatic basket cleaning machine includes a frame body 1, and the frame body 1 is equipped with a conveying mechanism 2, a basket high-pressure washing mechanism 3, and a rotary basket drying device 4 And an automatic packaging collection mechanism 5, the conveying mechanism 2 includes several rotatable roller bodies 21, the drive motor unit 22 that drives the roller body 21 to rotate, and the drive motor unit 22 passes through the belt body and the roller The wheel body 21 is arranged in drive connection. The basket high-pressure flushing mechanism 3 includes two high-pressure flushing chambers 31 and an angle rotating disk 32 for changing the basket conveying direction. The high-pressure flushing chambers are respectively a first high-pressure flushing chamber 311 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com