Universal detachable head and using method thereof

A technology of cornbread and head, which is applied in the field of new universal detachable cornbread, can solve problems such as production failure, assembly work being stuck in a bottleneck, affecting production progress and skin processing surface quality, and achieving the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

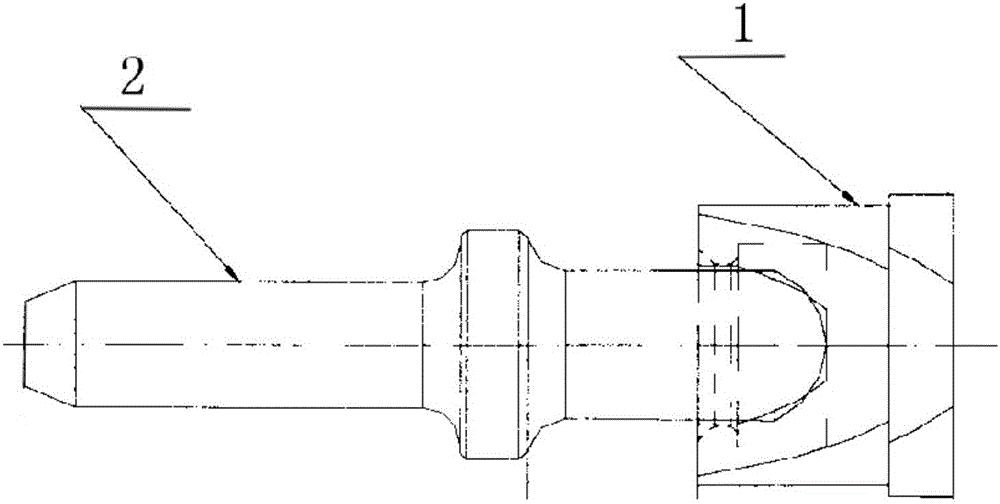

[0020] A universal detachable nest head, the structure of which is as follows figure 1 As shown, it adopts a split structure, which is composed of the working part 1 and the connecting rod part 2 of the steamer;

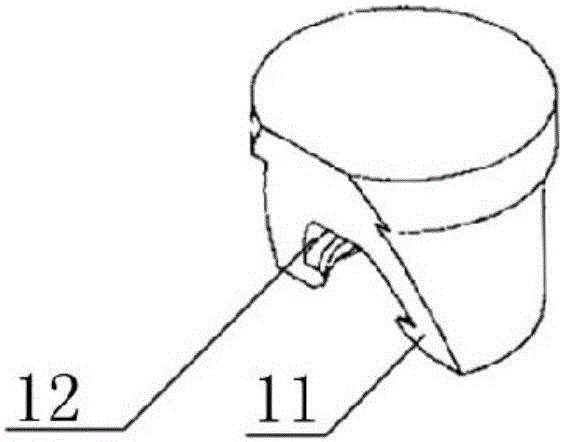

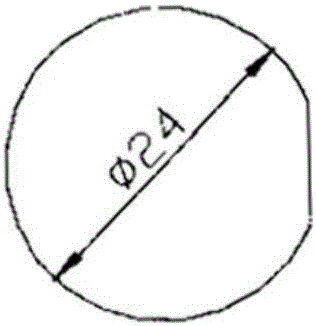

[0021] The outer surface of the working part 1 is stepped, such as Figure 2-5 As shown, the size of the large end of the step table is φ24mm, the size of the small end is φ22mm, and the total length is 20mm. Its left end face is a working surface 11; the inside of the working part is a hollow structure, and the inner end face of the hollow structure is in the form of an inner boss 12, which is used to limit the extraction of the socket connecting part from the working part of the socket; the outer surface of the working part An inclined plane 13 is milled out on the surface, the angle of the inclined plane 13 is 19°, and the distance from the small end is 15mm, so that the connecting rod part of the cornbread can be easily installed into the working part of the cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com