Clamping device of molds of engraving-milling machines

A kind of engraving and milling machine and clamping technology, which is applied in the direction of positioning device, clamping, manufacturing tools, etc., can solve the problems of laborious mold fixing, damaged mold, mold stability cannot be guaranteed, etc., and achieve the effect of stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

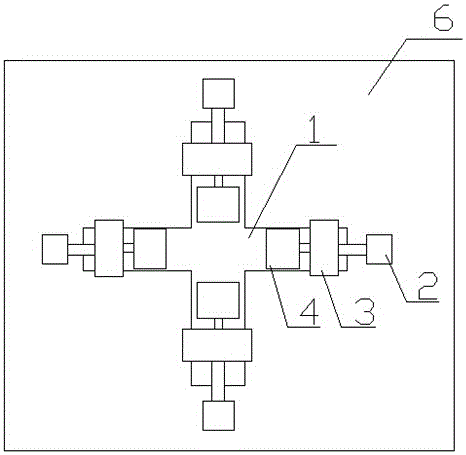

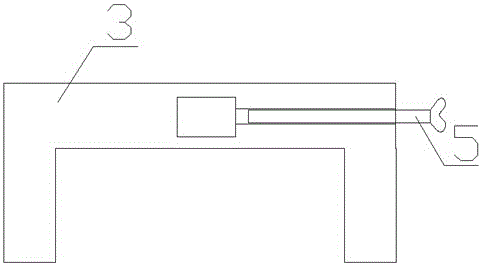

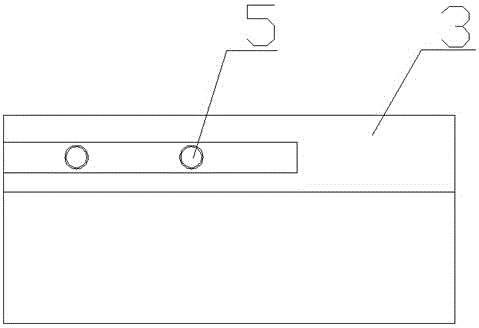

[0015] Such as figure 1 As shown, the present invention discloses a clamping device for engraving and milling machine molds, comprising: slide rail 1, cylinder 2, slider 3, splint 4, butterfly screw 5, machine tool 6, and the slide rail 1 is welded on 6 on the machine tool, the slide rail 1 is provided with four identical clamping groups, the clamping group includes: slide rail 1, cylinder 2, slider 3, splint 4, and the cylinder 2 is connected by bolts On the machine tool, and the cylinder 2 is at the right end of the slide rail 1, the slide frame on the slide rail 1 is provided with a slide block 3, and the slide block 3 is a U-shaped slide block 3, and the slide block 3 is connected to the cylinder 2 by bolts. The piston rod is connected, the left end of the slider 3 is connected to a splint 4 through a butterfly screw 5, and the splint 4 is on the upper surface of the slide rail 1.

[0016] The slider 3 is clamped on the slide rail 1 by the U-shaped side wall of the slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com