Automatic bookbinding machine

A technology of automatic binding and moving mechanism, which is applied in binding, book binding flattening machine, book binding, etc. It can solve the problems of paper easy to scatter, limited practical effect, and irregular documents, etc., and achieves good binding action and structure Simple, good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

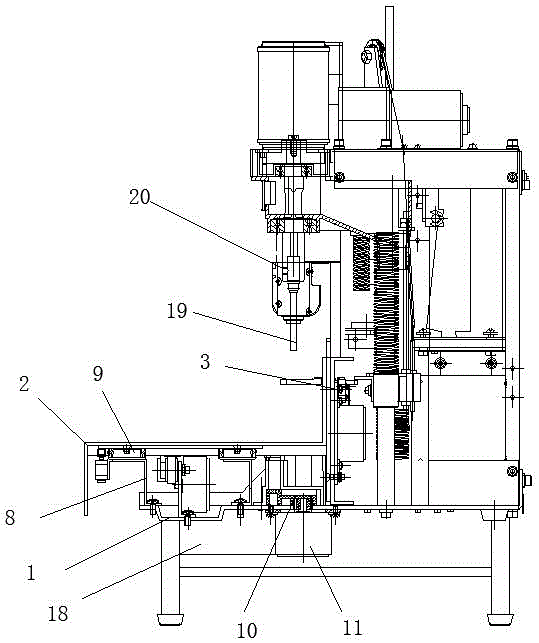

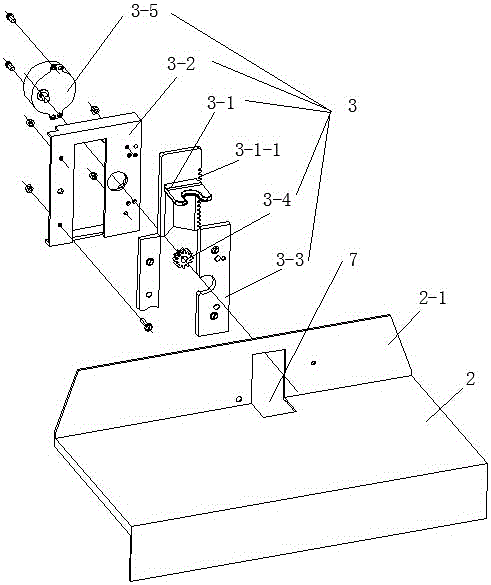

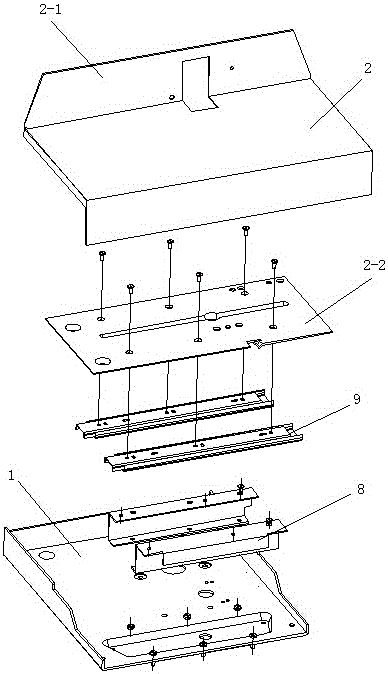

[0023] like Figure 1 to Figure 4 As shown, the embodiment of the present invention includes a paper press table 18, a drilling device 19, a hot riveting device 20, a lower riveting seat 5 and a knife pad seat 6, and the drilling device 19 and the hot riveting device 20 are along a direction perpendicular to the surface of the paper pressing table 18. The lower riveting seat 5 is set on the hot riveting device 20, the knife pad 6 is set under the drilling device 19, and the bottom plate 1 is returned; the table top 2, the table top 2 is set above the bottom plate 1; the paper pressing device 3 The paper pressing device 3 is arranged above the table top 2, and the paper pressing device 3 at least includes a paper pressing board 3-1 which is vertically vertical to the surface direction of the table top 2; For reciprocating movement relative to the base plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com