Gap filling automatic connection system

An automatic connection and gap filling technology, applied in railway car body parts, transportation and packaging, etc., can solve problems such as hidden safety hazards and passenger panic, and achieve the effect of enhancing safety assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

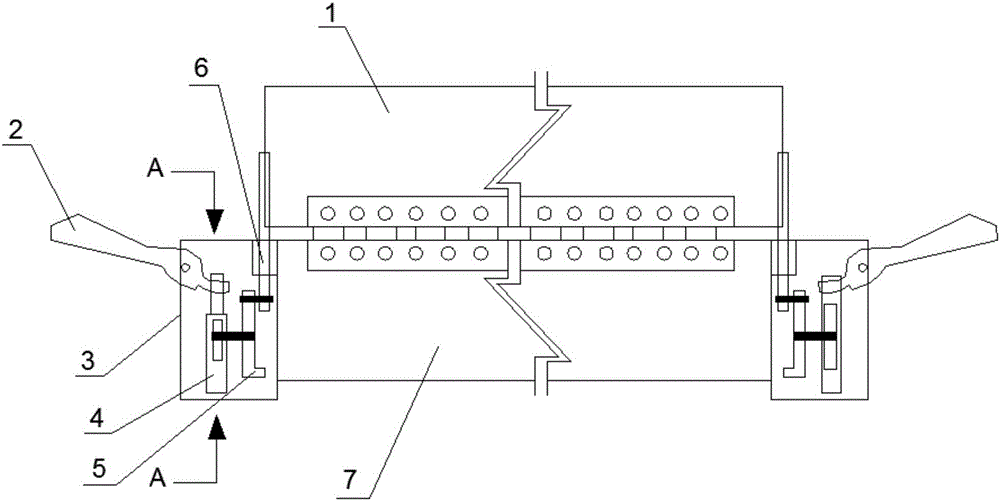

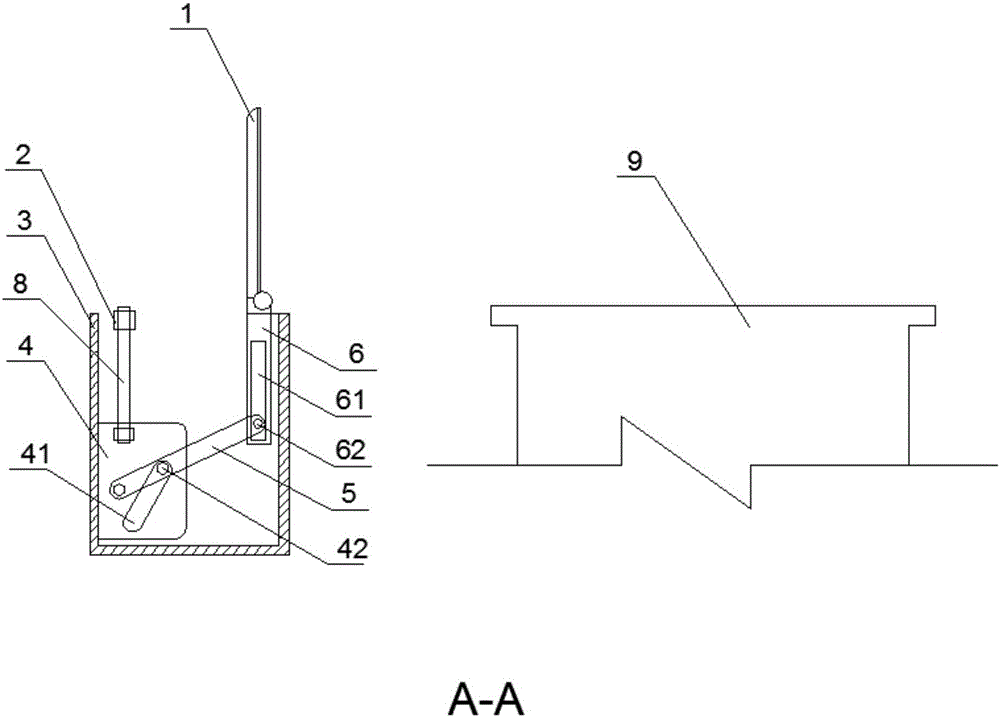

[0018] Gap filling automatic joining systems such as Figure 1-3 As shown, including starting connector box 3, starting lever 2 and link lever 6, starting lever 2 and link lever 6 are all hinged with starting connector box 3, and starting lever 2 is connected with movable clutch plate 4, and starting lever 2 drives movable clutch Plywood 4 moves up and down, movable clutch plate 4 is provided with first chute 41, also comprises relay rod 5, and one end of relay rod 5 is hinged with movable clutch plate 4, and the other end of relay rod 5 is hinged with link rod 6, and relay rod 5 is also provided with a first pin shaft 42 and a second pin shaft 62, the first pin shaft 42 slides in the first chute 41, the link rod 6 is provided with a second chute 61, the second pin shaft 62 slides in the second chute Sliding in the slot 61, the link rod 6 is provided with a rotary pedal 1. A connecting rod 8 is arranged between the starting rod 2 and the movable clutch plate 4, and one end of...

Embodiment 2

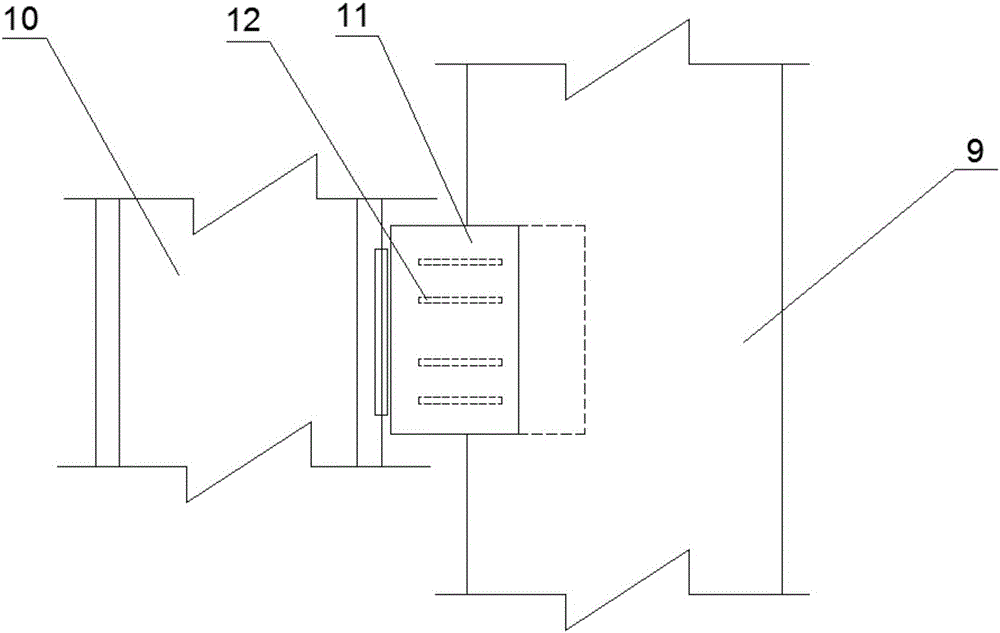

[0023] The same as embodiment 1, the difference is that it also includes a telescopic rod 12, which is used to be arranged on the platform 9, and the telescopic rod 12 is provided with a telescopic pedal 11. When there is a platform protective door, and when the rotary pedal 1 is not suitable for putting down, the platform 9 protective door is opened, and the telescopic rod 12 on the platform 9 rises the telescopic pedal 11 to the train door; the platform 9 protective door is closed, and the telescopic rod 12 will Telescoping pedal 11 retracts to platform 9. The gap between the train 10 and the platform 9 is filled by the telescopic rod 12 and the telescopic pedal 11 to prevent passengers from straying into the gap and causing danger.

Embodiment 3

[0025] Same as embodiment 1, the difference is that the thickness of the rotary pedal 1 is 2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com