Buffer type dairy cow milking stall

A cow stand technology, applied in the field of animal husbandry, can solve problems such as easy trampling, trampling accidents, hidden safety hazards, etc., and achieve the effect of convenient milking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

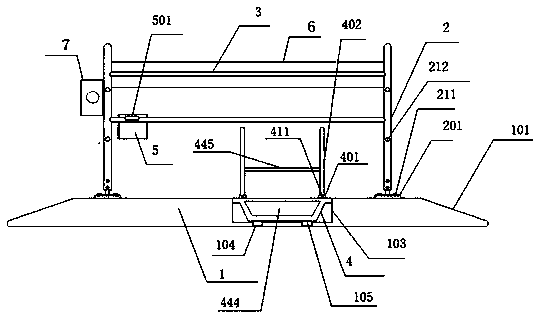

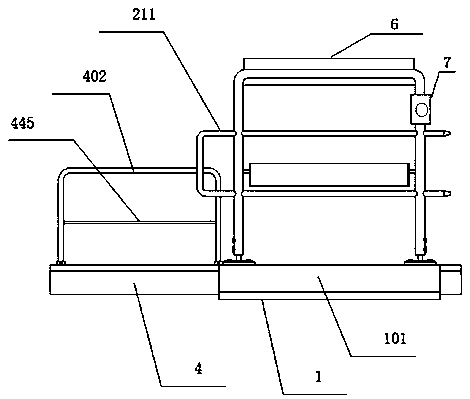

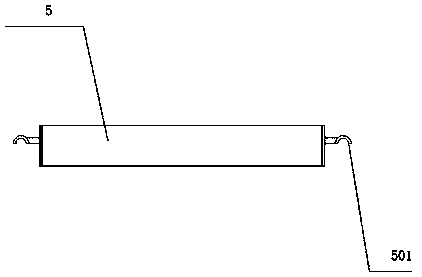

[0015] see Figure 1-3 , a kind of buffer cow milking hook fence, including a standing platform 1 for carrying cows, the left and right sides of the standing platform 1 are provided with slopes 101, and above the standing platform 1, there are two left and right parallel A "door"-shaped stand 2, a plurality of connecting frame rods 3 are welded between the two standing stands 2; each connecting frame rod 3 is equipped with an inflatable buffer sleeve 6, and each inflatable buffer sleeve 6 are all connected with the air pump 7 installed on the upper end of the stand 2 through pipelines;

[0016] A connecting plate 201 is fixedly installed inside the stand 2, and a bolt 211 is fitted between the connecting plate 201 and the standing platform 1, and a groove 103 is arranged on the top of the standing platform 1, the groove 103 runs through the stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com