Testing device and method for aerial refueling equipment

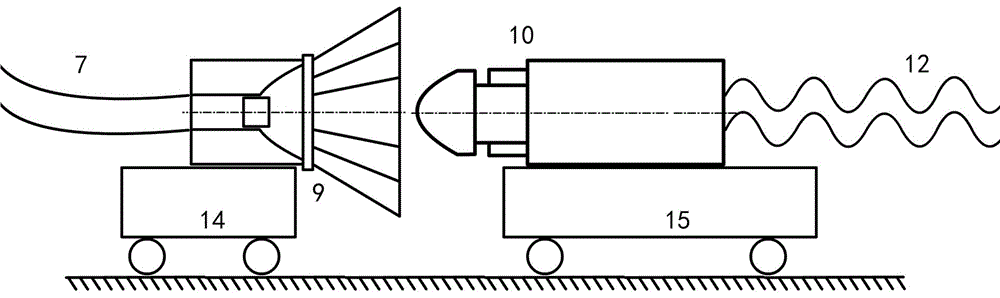

A technology for aerial refueling and test equipment, which is applied to ground equipment, transportation and packaging, aircraft parts, etc., can solve the problems of inability to conduct deviation tests, inability to accurately reflect the docking situation, and the inability to truly reflect the air docking situation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

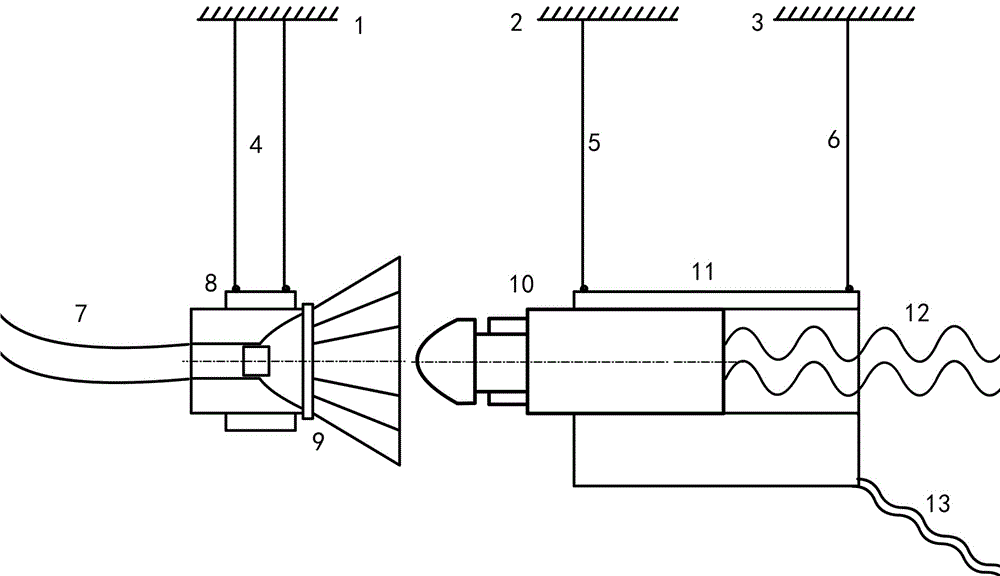

[0012] Such as figure 2 As shown, the taper sleeve holder 8 is suspended on the suspension point 1 with the suspension device 4, and the taper sleeve 9 and the flexible pipe 7 connecting the taper sleeve can be fixed. Normal oil pressure for aerial use can be established in the hose.

[0013] The oil receiving plug holder 11 is suspended on the suspension points 2,3 with the suspension devices 5,6. The inside of the oil plug holder is a water tank, which is connected to the water pipe 13. The oil receiving plug 10 can be fixed on the oil receiving plug holder 11 . The oil receiving plug 10 is connected with a flexible pipe 12, and the flexible pipe 12 can lead to a fuel tank for storing fuel.

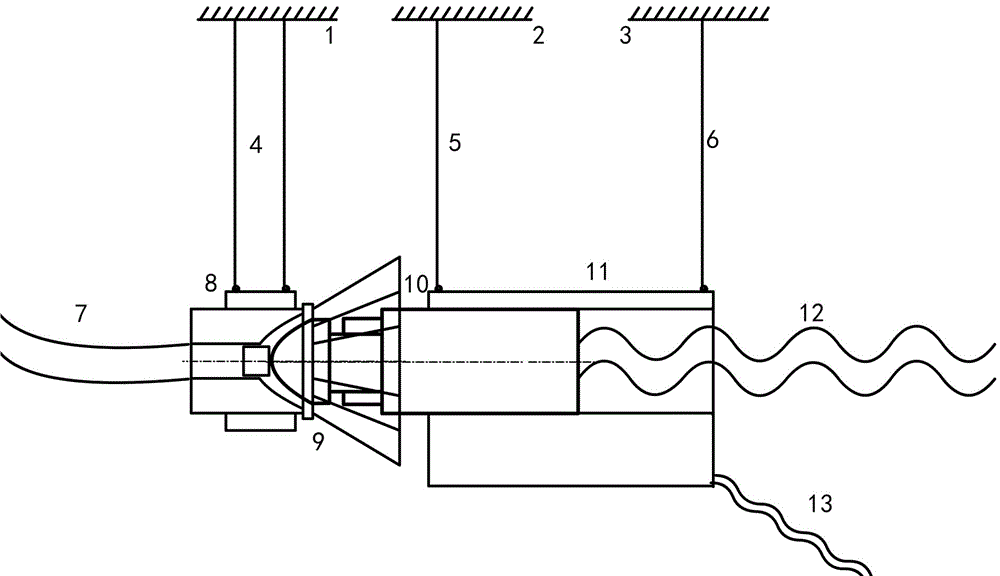

[0014] Suspension points 1, 2, and 3 can move forward, backward, left, and right respectively. When the taper sleeve 9 is docked with the oil receiving plug 10 and locked, and the suspension device 4, 5, 6 is vertical and free to rest as image 3 , record the positions of suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com