A high-precision garbage conveyor

A technology of garbage conveying and accuracy, applied in conveyors, conveyor objects, mechanical equipment, etc., can solve the problems of weak stability, easy overheating of driving coils, and high cost, and achieve the advantages of light weight, simple structure, cost, and high cost. weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

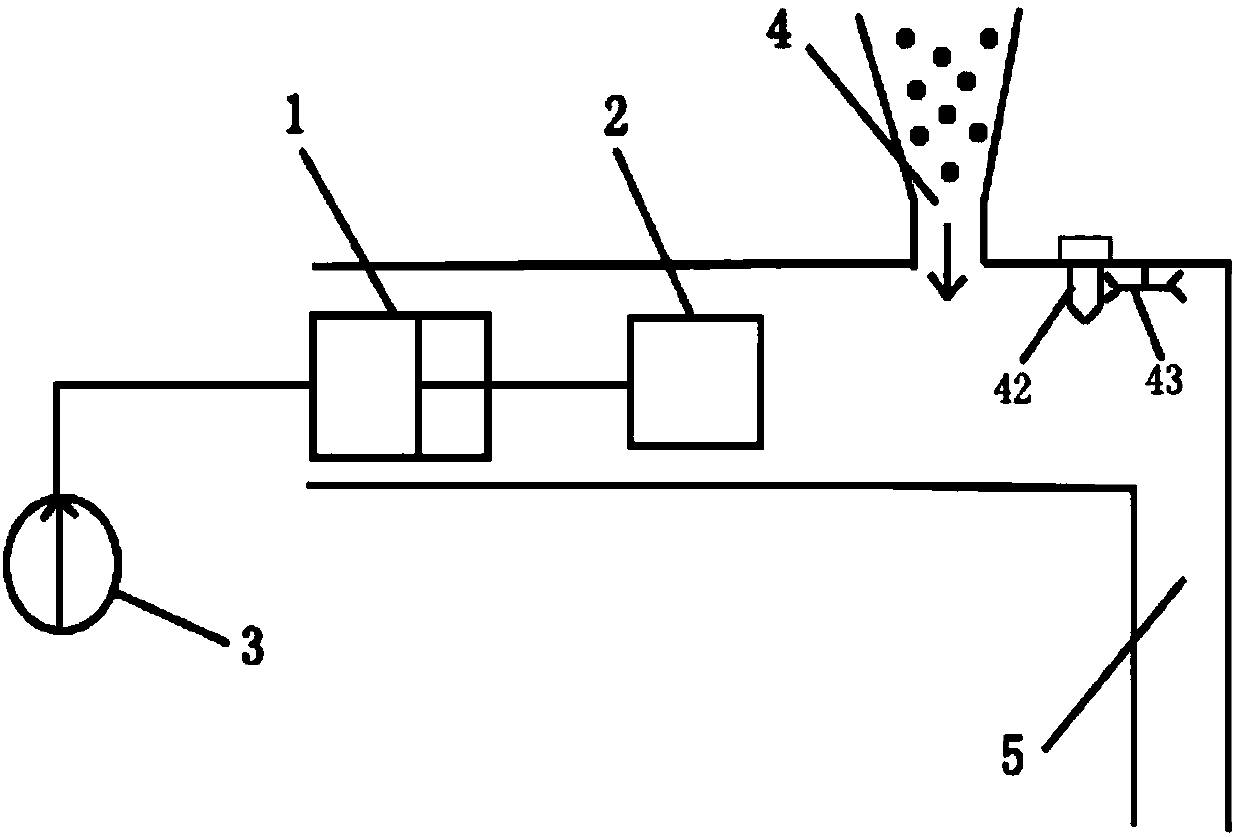

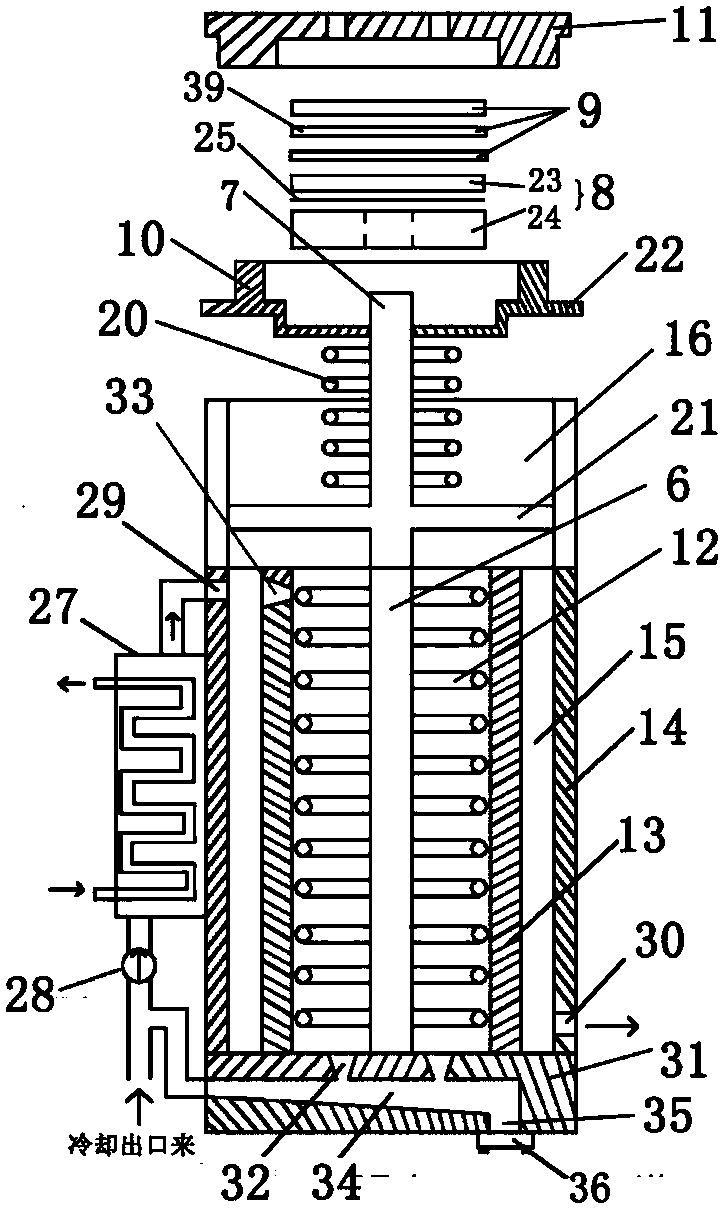

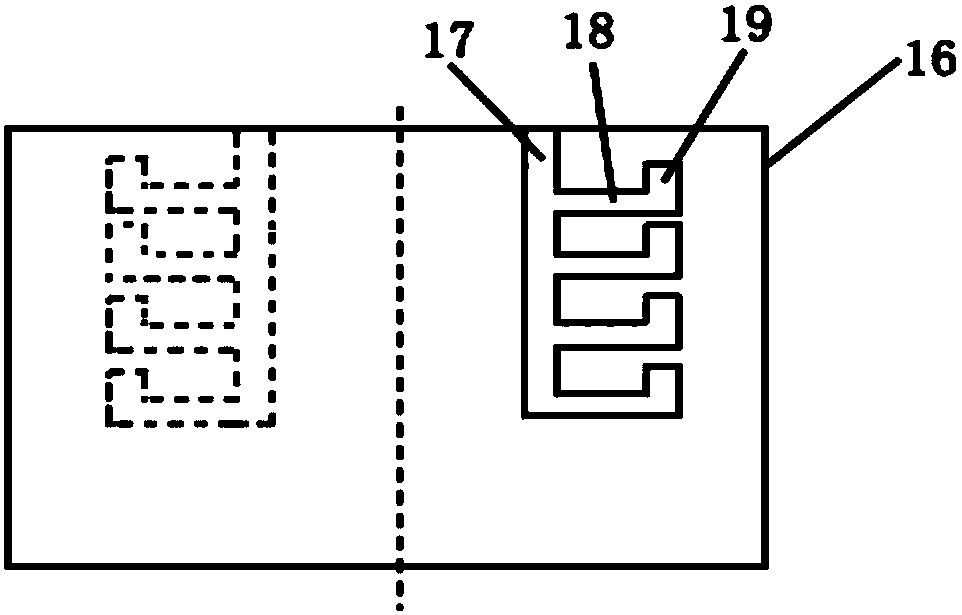

[0030] Such as figure 1 The shown high-precision garbage conveyor includes a hydraulic cylinder 1 and a propeller 2 connected to the hydraulic cylinder 1. The propeller 2 is used to push the garbage falling from the discharge port 4 into the discharge port 5. The hydraulic cylinder 1 is supplied with oil by giant magnetostrictive pump 3. The right side of the discharge opening 4 is provided with a hydraulic puncture needle 42, and the hydraulic puncture needle 42 is driven by hydraulic oil to perform periodic movement up and down to pierce bags in the garbage; the right side of the hydraulic puncture needle 42 A rotary brush 43 is arranged on the side, which is used to clean up the flexible hanging objects on the hydraulic puncture needle 42 . The rotary brush 43 is arranged horizontally, and the brush at the left end is in close contact with the body of the hydraulic puncture needle 42 . The rotary brush 43 is driven by a motor to rotate at a low speed, and is linked with t...

Embodiment 2

[0041] Such as figure 1 The shown high-precision garbage conveyor includes a hydraulic cylinder 1 and a propeller 2 connected to the hydraulic cylinder 1. The propeller 2 is used to push the garbage falling from the discharge port 4 into the discharge port 5. The hydraulic cylinder 1 is supplied with oil by giant magnetostrictive pump 3. The right side of the discharge opening 4 is provided with a hydraulic puncture needle 42, and the hydraulic puncture needle 42 is driven by hydraulic oil to perform periodic movement up and down to pierce bags in the garbage; the right side of the hydraulic puncture needle 42 A rotary brush 43 is arranged on the side, which is used to clean up the flexible hanging objects on the hydraulic puncture needle 42 . The rotary brush 43 is arranged horizontally, and the brush at the left end is in close contact with the body of the hydraulic puncture needle 42 . The rotary brush 43 is driven by a motor to rotate at a low speed, and is linked with t...

Embodiment 3

[0052] Such as figure 1 The shown high-precision garbage conveyor includes a hydraulic cylinder 1 and a propeller 2 connected to the hydraulic cylinder 1. The propeller 2 is used to push the garbage falling from the discharge port 4 into the discharge port 5. The hydraulic cylinder 1 is supplied with oil by giant magnetostrictive pump 3. The right side of the discharge opening 4 is provided with a hydraulic puncture needle 42, and the hydraulic puncture needle 42 is driven by hydraulic oil to perform periodic movement up and down to pierce bags in the garbage; the right side of the hydraulic puncture needle 42 A rotary brush 43 is arranged on the side, which is used to clean up the flexible hanging objects on the hydraulic puncture needle 42 . The rotary brush 43 is arranged horizontally, and the brush at the left end is in close contact with the body of the hydraulic puncture needle 42 . The rotary brush 43 is driven by a motor to rotate at a low speed, and is linked with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com