A strong controllable automatic adjustment cloth device

A material distribution device and automatic adjustment technology, applied in the material field, can solve the problems of insufficient automatic adjustment accuracy and complex structure, and achieve the effects of light weight, enhanced cooling effect, and reduced integrated weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

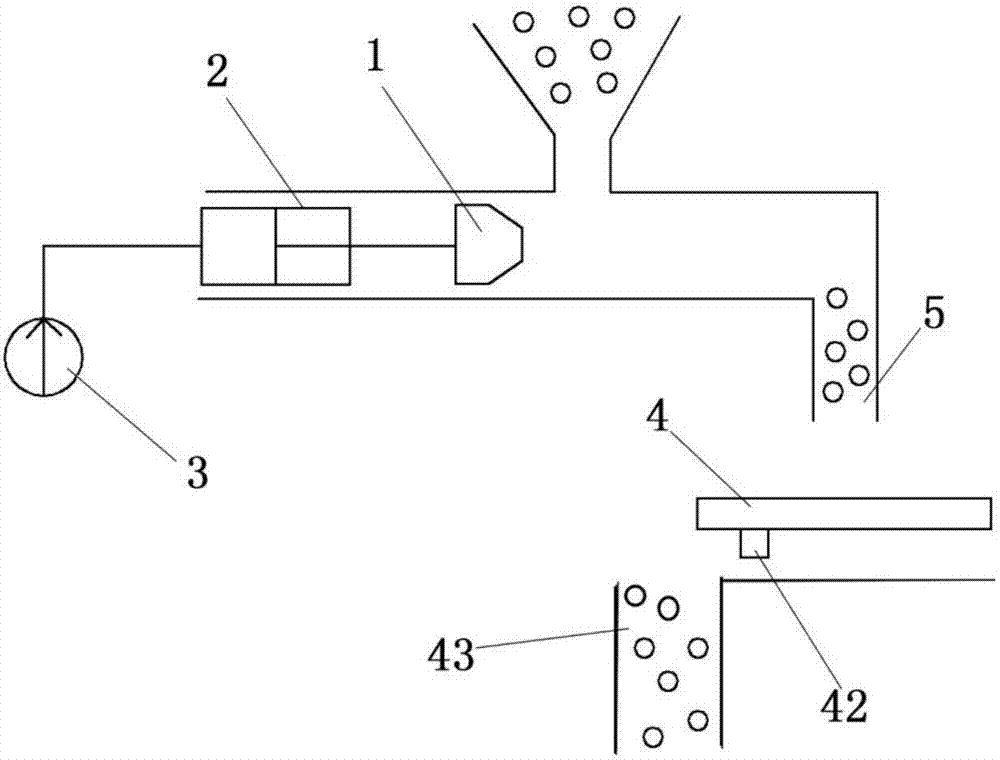

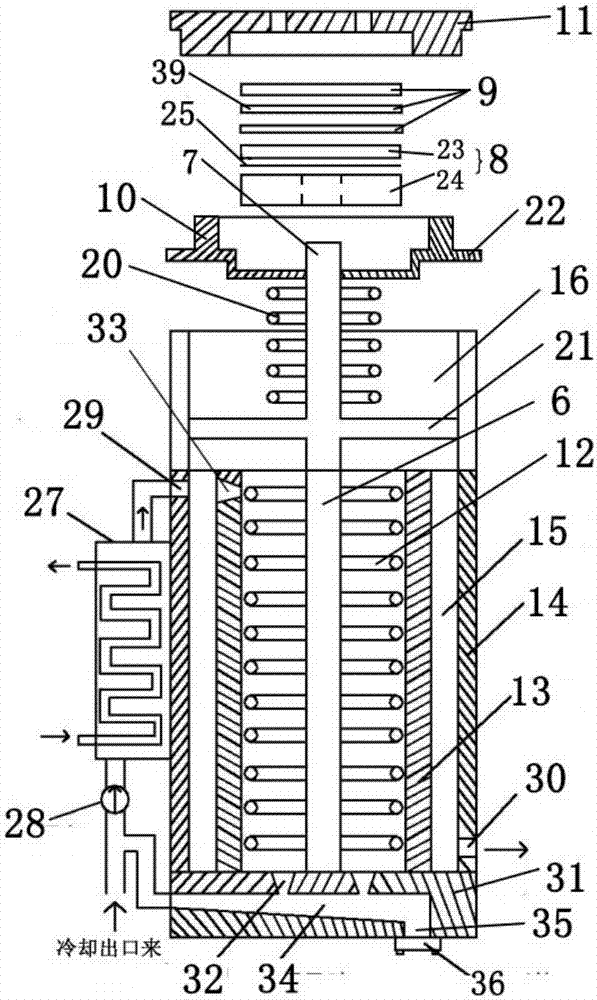

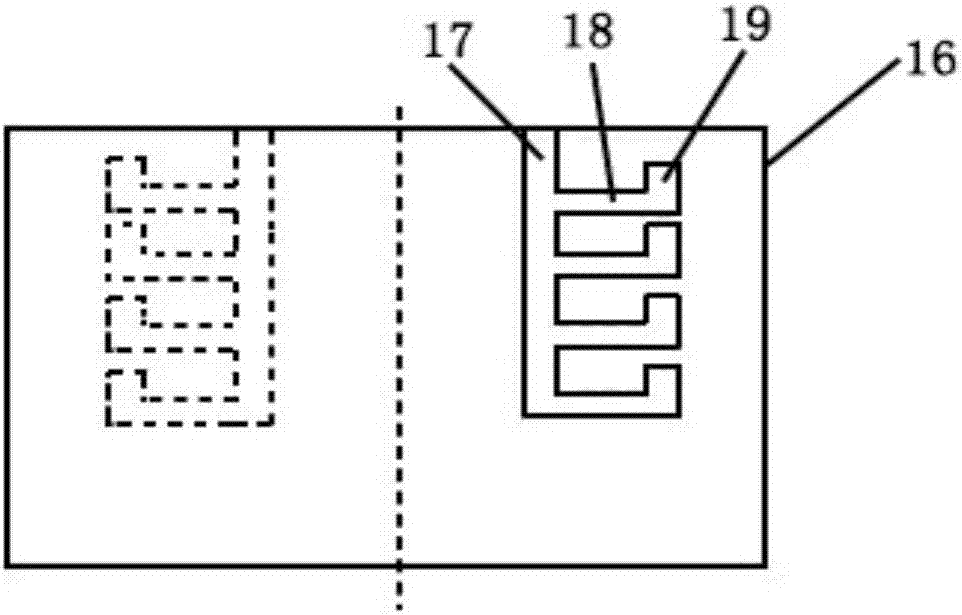

[0031] Such as figure 1 The shown one kind of strong controllable automatic adjustment material distributing device includes a pusher 1, a hydraulic cylinder 2, an oil supply pump, a transfer conveyor belt 4 and a controller; the pusher 1 is driven by a hydraulic cylinder 2, and the hydraulic cylinder 2 is supplied by a The oil pump supplies oil. The transfer conveyor belt 4 is arranged below the transfer outlet 5 , and a weight sensor 42 is installed on the transfer conveyor belt 4 . When the material distributing device is working, the pusher 1 pushes the material falling from the inlet into the transfer outlet 5, then falls on the transfer conveyor belt 4, and finally is sent to the discharge port 43 by the transfer conveyor belt 4, and the controller according to the weight The weight change rate fed back by the sensor 42 is used to control the oil supply volume of the oil supply pump. When the change rate is greater than 0, it means that the material entering the transfe...

Embodiment 2

[0042] Such as figure 1 The shown one kind of strong controllable automatic adjustment material distributing device includes a pusher 1, a hydraulic cylinder 2, an oil supply pump, a transfer conveyor belt 4 and a controller; the pusher 1 is driven by a hydraulic cylinder 2, and the hydraulic cylinder 2 is supplied by a The oil pump supplies oil. The transfer conveyor belt 4 is arranged below the transfer outlet 5 , and a weight sensor 42 is installed on the transfer conveyor belt 4 . When the material distributing device is working, the pusher 1 pushes the material falling from the inlet into the transfer outlet 5, then falls on the transfer conveyor belt 4, and finally is sent to the discharge port 43 by the transfer conveyor belt 4, and the controller according to the weight The weight change rate fed back by the sensor 42 is used to control the oil supply volume of the oil supply pump. When the change rate is greater than 0, it means that the material entering the transfe...

Embodiment 3

[0053] Such as figure 1 The shown one kind of strong controllable automatic adjustment material distributing device includes a pusher 1, a hydraulic cylinder 2, an oil supply pump, a transfer conveyor belt 4 and a controller; the pusher 1 is driven by a hydraulic cylinder 2, and the hydraulic cylinder 2 is supplied by a The oil pump supplies oil. The transfer conveyor belt 4 is arranged below the transfer outlet 5 , and a weight sensor 42 is installed on the transfer conveyor belt 4 . When the material distributing device is working, the pusher 1 pushes the material falling from the inlet into the transfer outlet 5, then falls on the transfer conveyor belt 4, and finally is sent to the discharge port 43 by the transfer conveyor belt 4, and the controller according to the weight The weight change rate fed back by the sensor 42 is used to control the oil supply volume of the oil supply pump. When the change rate is greater than 0, it means that the material entering the transfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com