A kind of preparation method of large-area nitrogen-doped carbon nanotube paper

A carbon nanotube and nanotube technology, which is applied in the field of large-area nitrogen-doped carbon nanotube paper and its preparation, can solve the problems of control method limitation, complex preparation process, and difficulty in meeting the requirements, and achieves simple equipment and strong controllability and operability. , the effect of easy direct application and batch preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

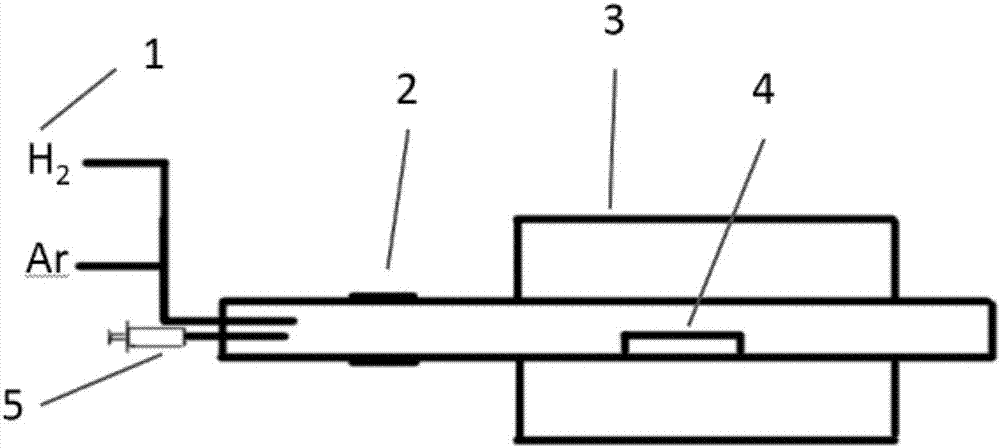

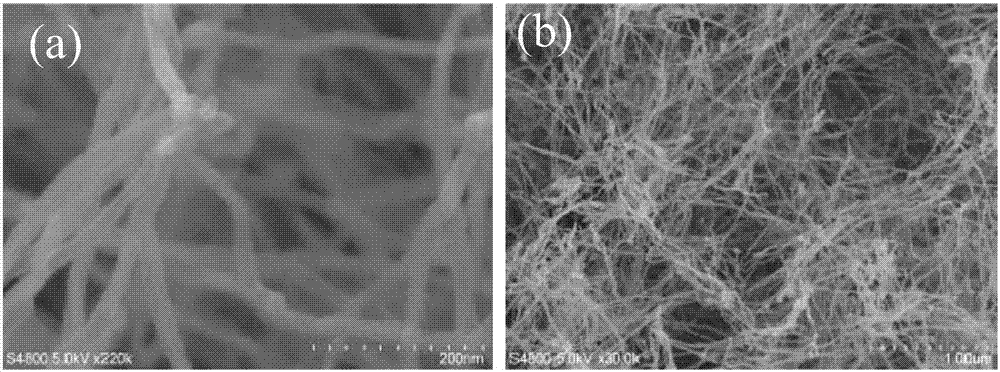

[0035] The invention adopts CVD method to prepare large-area nitrogen-doped carbon nanotube paper. The preparation method of the nitrogen-doped carbon nanotube paper comprises the following steps:

[0036] 1) take by weighing ferrocene powder ((C 5 h 5 ) 2 Fe) dissolved in dichlorobenzene (C 6 h 4 Cl 2 ), it is prepared into a ferrocene / dichlorobenzene carbon source solution with a concentration of 20-150mg / mL; measure a certain amount of pyridine (C 5 h 5 N) mixed with ferrocene / dichlorobenzene carbon source solution to form ferrocene / dichlorobenzene / pyridine mixed carbon source solution, the ratio of pyridine to dichlorobenzene is controlled at 1:1~1:2;

[0037] 2) Curl the base of the iron sheet or copper sheet into a cylindrical shape and put it into the quartz reaction chamber of the reaction furnace, and make it as close as possible to the inner wall of the quartz reaction chamber to seal the reaction chamber, and flow argon with a flow rate of 100-500mL / min into ...

Embodiment 1

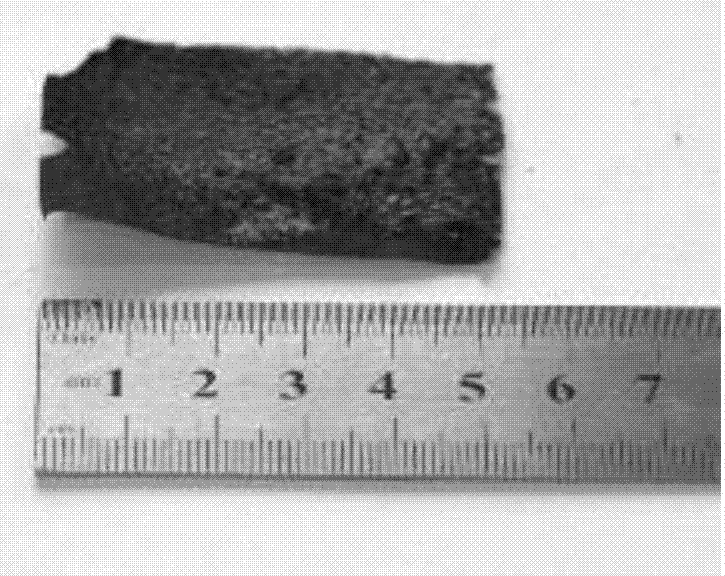

[0043] Weigh 4.0g of ferrocene powder and dissolve it in 100mL of dichlorobenzene to prepare a ferrocene / dichlorobenzene carbon source solution with a concentration of 40mg / mL; measure 1mL of pyridine and 10ml of ferrocene / dichlorobenzene carbon The source solutions are mixed to form a ferrocene / dichlorobenzene / pyridine mixed carbon source solution, and the ratio of pyridine to dichlorobenzene is 1:10.

[0044]Ultrasonic the copper sheet with the size of 18cm×20cm×0.1cm for 15 minutes, curl it into a cylindrical shape and put it into the quartz reaction chamber of the reaction furnace, and make it as close as possible to the inner wall of the quartz reaction chamber to seal the reaction chamber, and to the reaction chamber Introduce argon gas with a flow rate of 100mL / min to exhaust the air in the reaction chamber, and heat the reaction furnace at the same time; Hydrogen, forming argon hydrogen mixed carrier gas.

[0045] Use a precision syringe pump to inject the ferrocene / d...

Embodiment 2

[0049] Weigh 4.0g of ferrocene powder and dissolve it in 100mL of dichlorobenzene to prepare a ferrocene / dichlorobenzene carbon source solution with a concentration of 40mg / mL; measure 1mL of pyridine and 5ml of ferrocene / dichlorobenzene carbon The source solutions are mixed to form a ferrocene / dichlorobenzene / pyridine mixed carbon source solution, and the ratio of pyridine to dichlorobenzene is 1:5.

[0050] Ultrasonic the copper sheet with the size of 18cm×20cm×0.1cm for 15 minutes, curl it into a cylindrical shape and put it into the quartz reaction chamber of the reaction furnace, and make it as close as possible to the inner wall of the quartz reaction chamber to seal the reaction chamber, and to the reaction chamber Introduce argon gas with a flow rate of 100mL / min to exhaust the air in the reaction chamber, and heat the reaction furnace at the same time; Hydrogen, forming argon hydrogen mixed carrier gas.

[0051] Use a precision syringe pump to inject the ferrocene / di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com