Electroslag furnace brush variable speed movement mechanism and control method

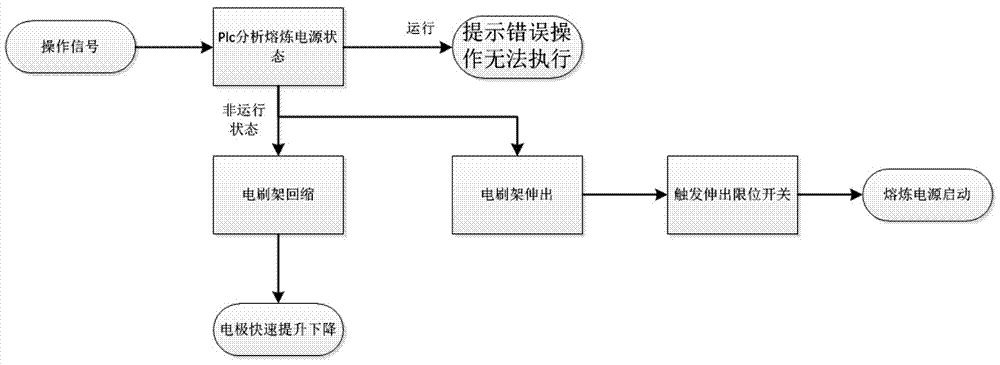

A technology of variable speed motion and brush mechanism, which is applied to the field of variable speed motion mechanism and control of electric slag furnace brushes, can solve the problems of increasing use cost, brush wear, limiting electrode moving speed and brush service life, etc., so as to improve production. effect, saving time and cost, avoiding the effect of early heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

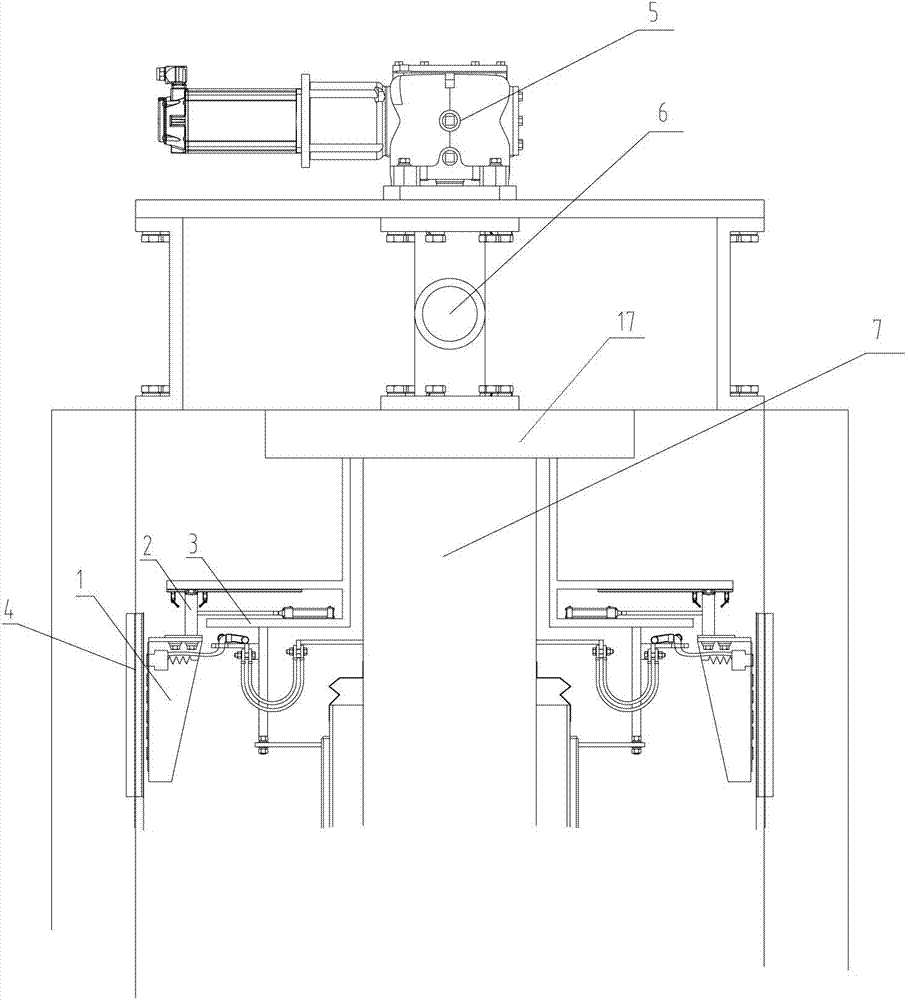

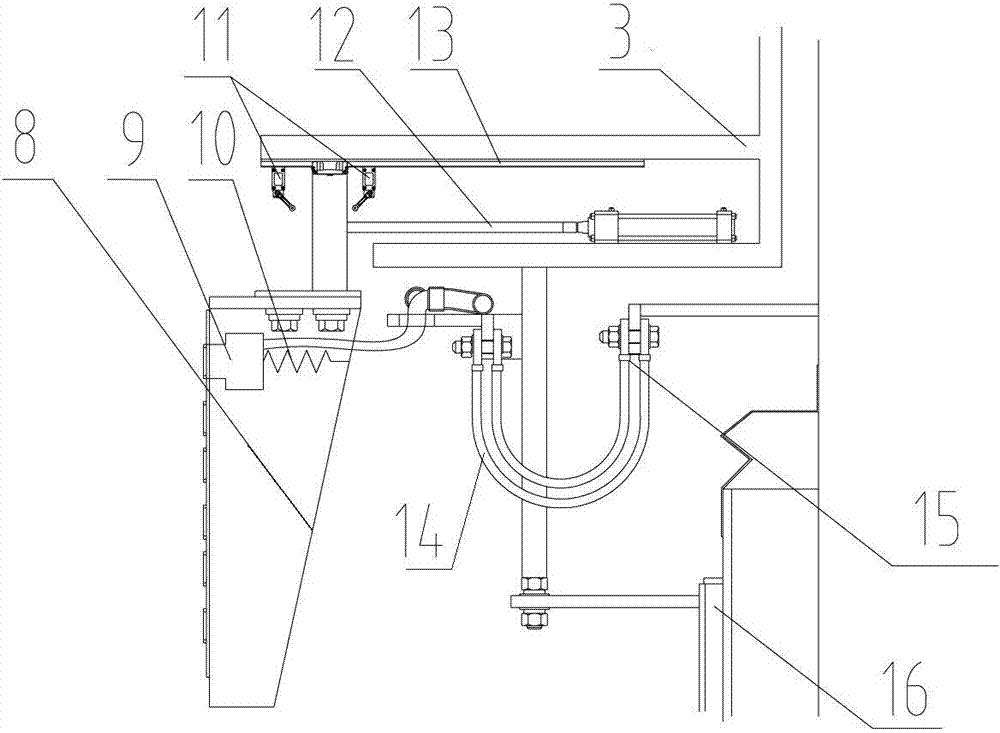

[0019] refer to figure 1 , 2 , an electroslag furnace brush variable speed movement mechanism, composed of a brush mechanism 1, a sliding actuator 2 and a fixed frame 3. The brush mechanism 1 is fixed on the lower end of the sliding actuator 2 , and the upper end of the sliding actuator 2 is fixed on the fixed frame 3 . The brush mechanism 1 includes a brush 9, a brush holder 8 and a spring 10, the brush 9 is fixed in the end face of the brush holder 8, and the brush 9 is a boss structure, wherein the boss part and the brush holder The openings on the end faces cooperate with each other, and the height of the boss controls the movement stroke of the brush, that is, the relative position of the brush is locked to a certain extent. One end can be stretched out to contact the conductive copper wall 4, and the other end is connected to the spring 10, the spring 10 is pressed against the brush holder 8, giving the brush a horizontal pressing force, so as to keep the brush surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com