Full-automatic rope washing machine

A washing machine, fully automatic technology, applied in liquid/gas/vapor rope fabric processing, textile and papermaking, liquid/gas/vapor textile processing, etc. Confusion, inaccurate detection signal and other problems, to achieve the effect of reliable detection method, compact structure and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

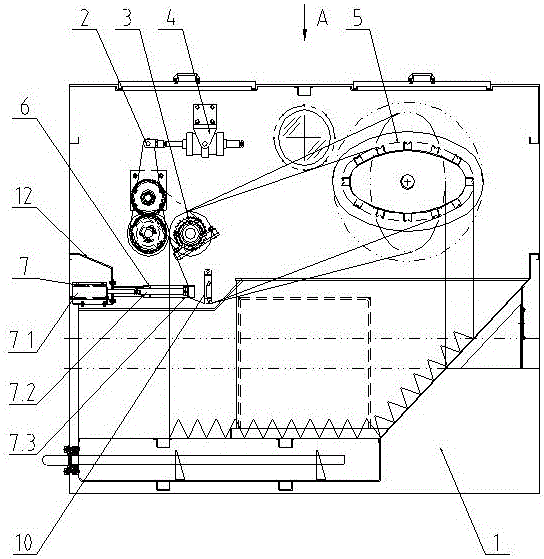

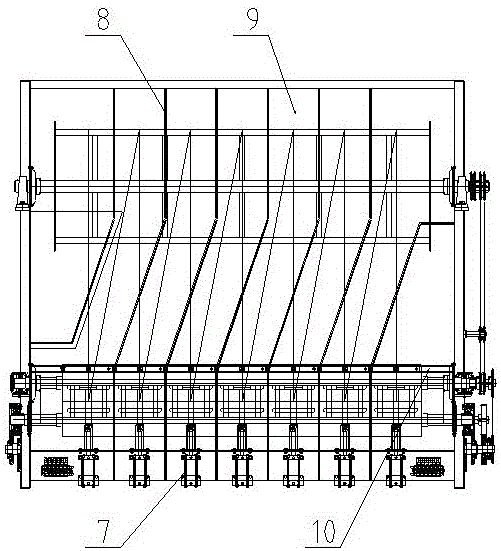

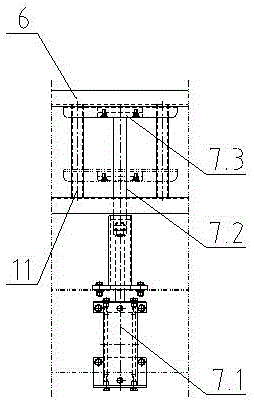

[0048] Such as Figure 1~Figure 4 As shown, a fully automatic rope-shaped washing machine in this embodiment includes a plurality of unit tanks, and the unit tanks include a water tank 1, and above the water tank 1, a roll group, a cloth doffing roller 5 and a cloth guide ring are arranged. 6. The cloth guide ring 6 is located below the roller group, and a plurality of partitions 8 are arranged on the roller group, the doffing roller 5 and the cloth guide ring 6, and the plurality of partitions 8 connect the roller group, the cloth doffing roller 5. The cloth guide ring 6 and the water tank 1 below it are divided into a plurality of cells 9, and each cell 9 is provided with a brake mechanism 7 on the left side of the cloth guide ring 6, and the brake mechanism 7 and the cloth guide ring 6 are located on the same horizontal line;

[0049] The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap