Ultra-thin aseismic pedestal

An anti-seismic support, ultra-thin technology, applied in the direction of anti-seismic, bridge parts, bridges, etc., can solve the problems of reduced anti-seismic performance, excessive size of the support, etc., achieve excellent bearing capacity, increase the bearing area, and avoid disorderly sliding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

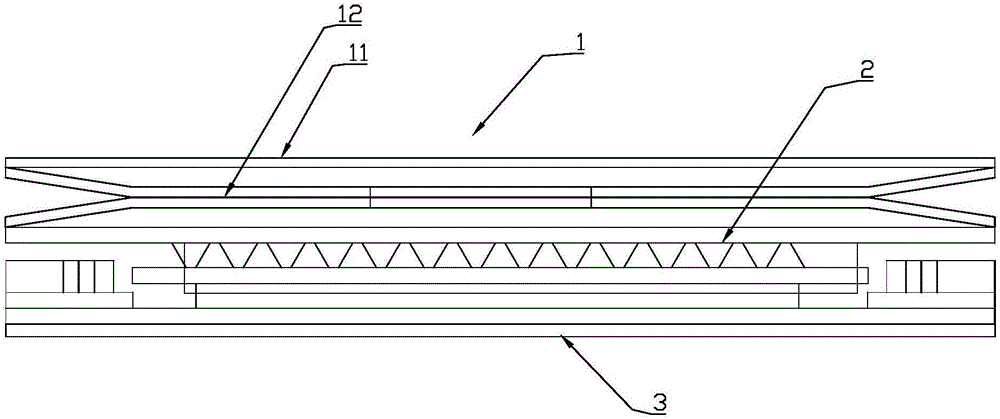

[0049] like Figure 1 to Figure 11 As shown, for existing defects, the subject of protection of the present invention is as follows:

[0050] What has been developed is an anti-seismic bearing, especially an ultra-thin anti-seismic bearing whose size in the height direction is compressed by at least half under the same anti-seismic performance.

[0051] Based on the above description, the specific structure of this support is as follows:

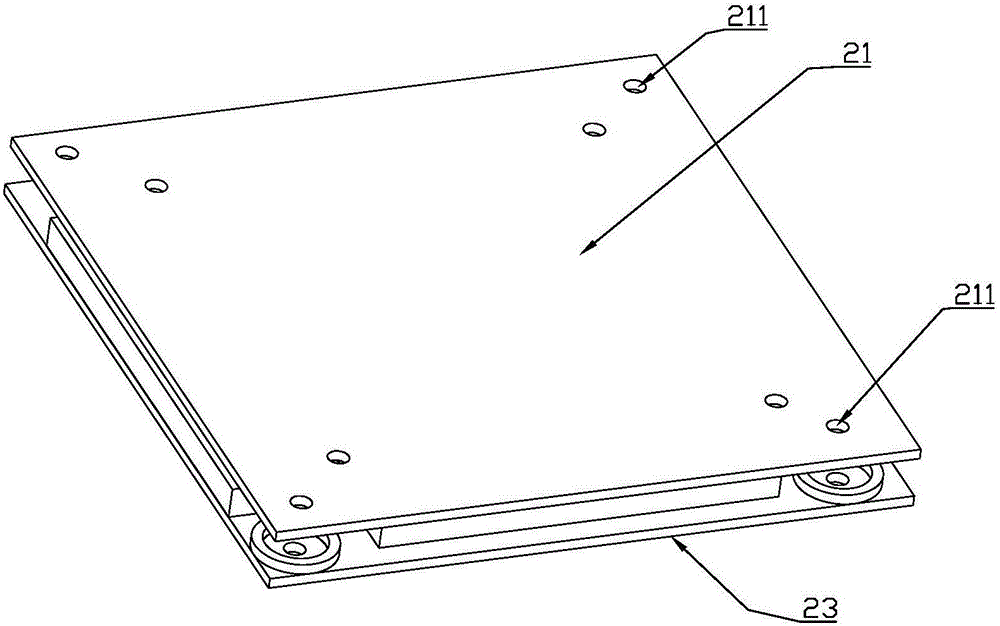

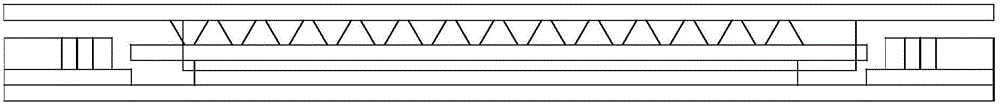

[0052] It includes upper, middle and lower parts. The upper part 1 is used to connect with supported objects, such as bridges and beams, and has the ability of elasticity in the vertical direction. The middle part 2 has the ability to dissipate vibration and impact in the horizontal direction. The lower part 3 is used for connecting with supporting beams and columns.

[0053] Among them, the ultra-thin support A is generally used between the bridge column and the bottom of the bridge beam, and is generally installed horizontally, so the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com