Direct-connection test equipment for simulating actual inlet conditions of scramjet engine isolation section and combustion chamber

A technology of actual entrance and scram pressing, which is applied in the field of aerodynamics, can solve the problem of non-starting of the direct connection test bench, and achieve the effect of solving the starting problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the accompanying drawings.

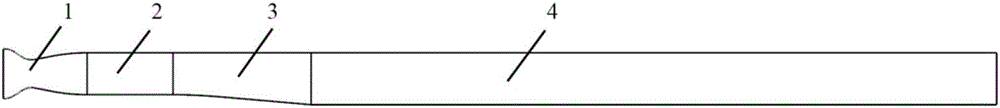

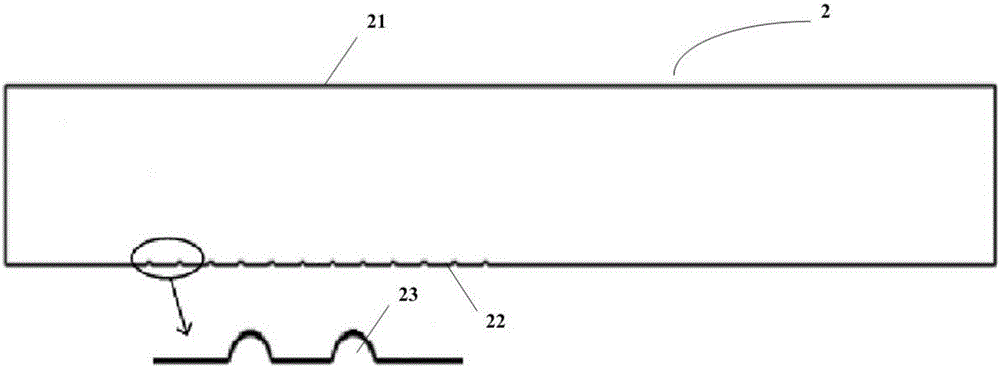

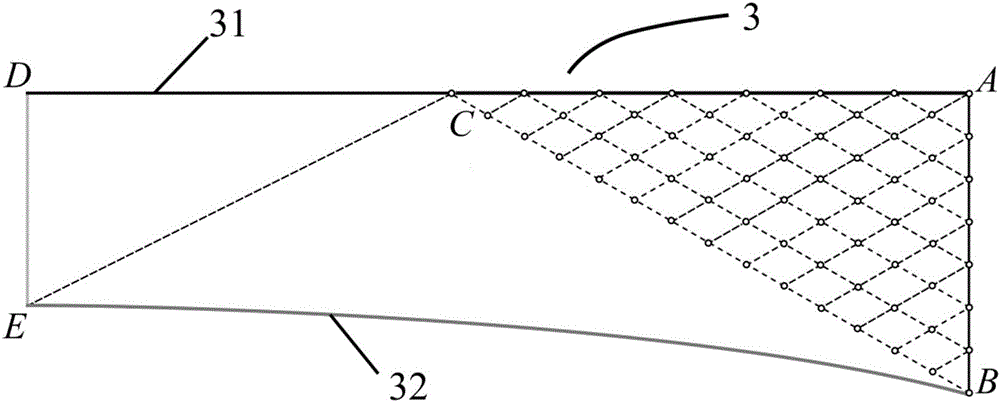

[0028] Such as figure 1 , figure 2 and image 3 As shown, a direct-connected test equipment for simulating the actual inlet conditions of the scramjet isolation section and the combustion chamber is characterized in that it includes the device nozzle 1 for accelerating the airflow to the target Mach number, and the nozzle 1 for producing the boundary layer. Boundary layer development section 2, expansion section 3 for generating precise oblique shock waves and engine isolation section model 4;

[0029] Equipment nozzle 1 in sequence, the outlet of equipment nozzle 1 is connected to the inlet of boundary layer development section 2, the outlet of boundary layer development section 2 is connected to the inlet of expansion section 3, and the outlet of expansion section 3 is connected to isolation section model 4;

[0030] The outlet of the equipment nozzle, the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com