Anti-melting effect tester for frozen drinks

A technology for frozen drinks and measuring instruments, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of inaccurate measurement results, many influencing factors, and difficult to control, so as to ensure the internal environment, improve accuracy and reliability, Simple structure and principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

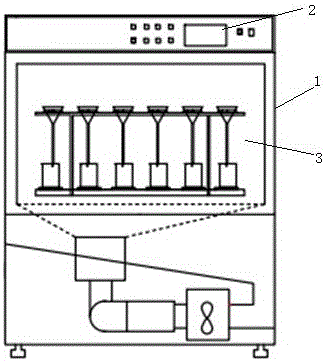

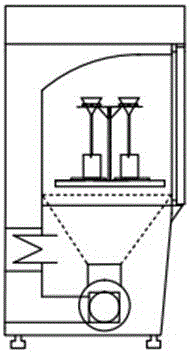

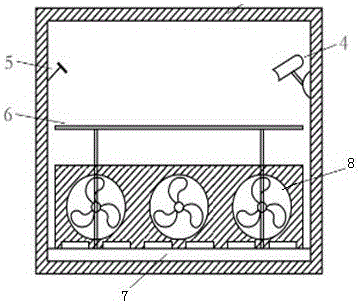

[0014] Such as Figure 1-3 As shown, an instrument for measuring the anti-thawing effect of frozen drinks is composed of a box body 1, a display and control system 2, a measurement chamber 3, and a variable temperature and circuit system. The display and control system is composed of a display area and a control system. The display area It is located at the upper part of the front of the box, and the control system is located at the middle of the front of the box. The measuring room is located at the upper part of the box, and the measuring room is wrapped with an insulation layer. A fan 8 is installed, and a temperature sensing probe 5 and a monitor 4 are installed on the upper part of the measuring chamber; the front of the measuring chamber is a door with a glass window; The system is composed of a heat exchange plate between the heating device, the cooling device and the weighing system, the circuit system supplies power to the display and control system, the measurement r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com