Fluorescent optical fiber temperature measurement system based on wireless sensing and method thereof

A fluorescent optical fiber and wireless sensing technology, applied in the field of fluorescent optical fiber temperature measurement system, can solve the problem of inaccurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

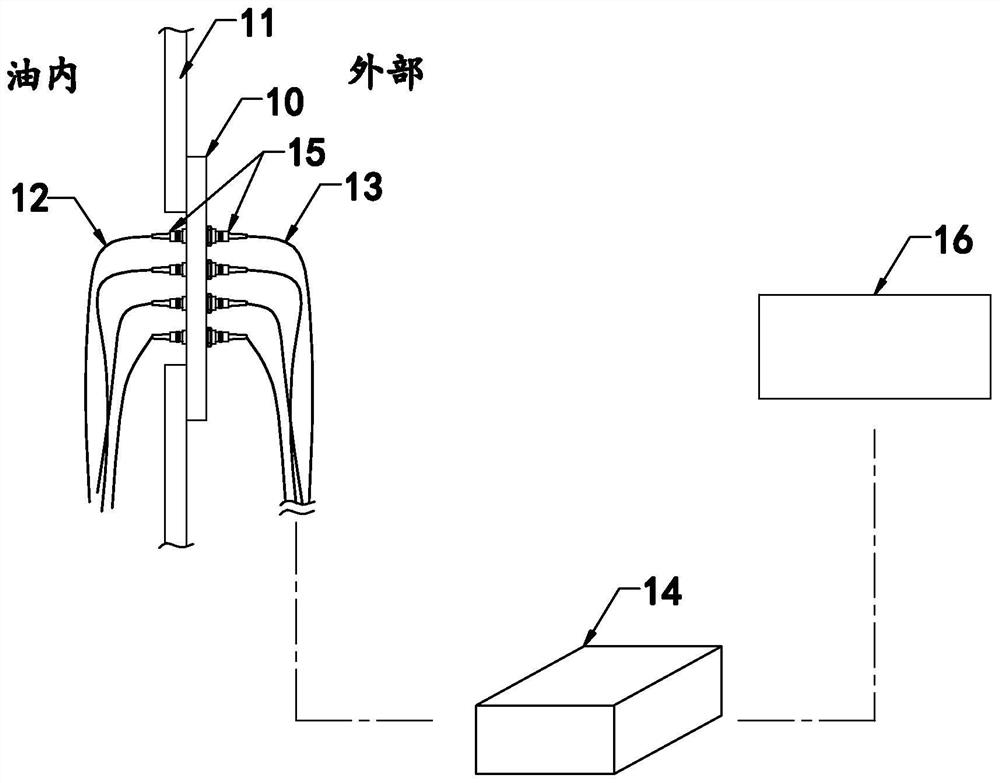

[0092] Such as figure 1 As shown, the invention discloses a fluorescent optical fiber temperature measurement system based on wireless sensing, characterized in that: comprising:

[0093] The through disk 10 is installed on the wall 11 of the transformer oil tank and has several optical fiber interfaces;

[0094] The oil-resistant optical fiber 12 is located in the transformer oil tank, and one end extends to the optical fiber interface, and the other end extends to the transformer winding, and an optical fiber probe is provided at this end;

[0095] An optical fiber jumper 13 is located outside the transformer, and one end extends to the optical fiber interface, and the other end is connected to an optical fiber temperature controller 14;

[0096] The through device 15 is arranged at each optical fiber interface, and is used to connect the oil-resistant optical fiber 12 and the optical fiber jumper 13;

[0097] The serial server 16 is connected with the optical fiber temper...

Embodiment 2

[0101] Embodiment 2, the difference with embodiment 1 is:

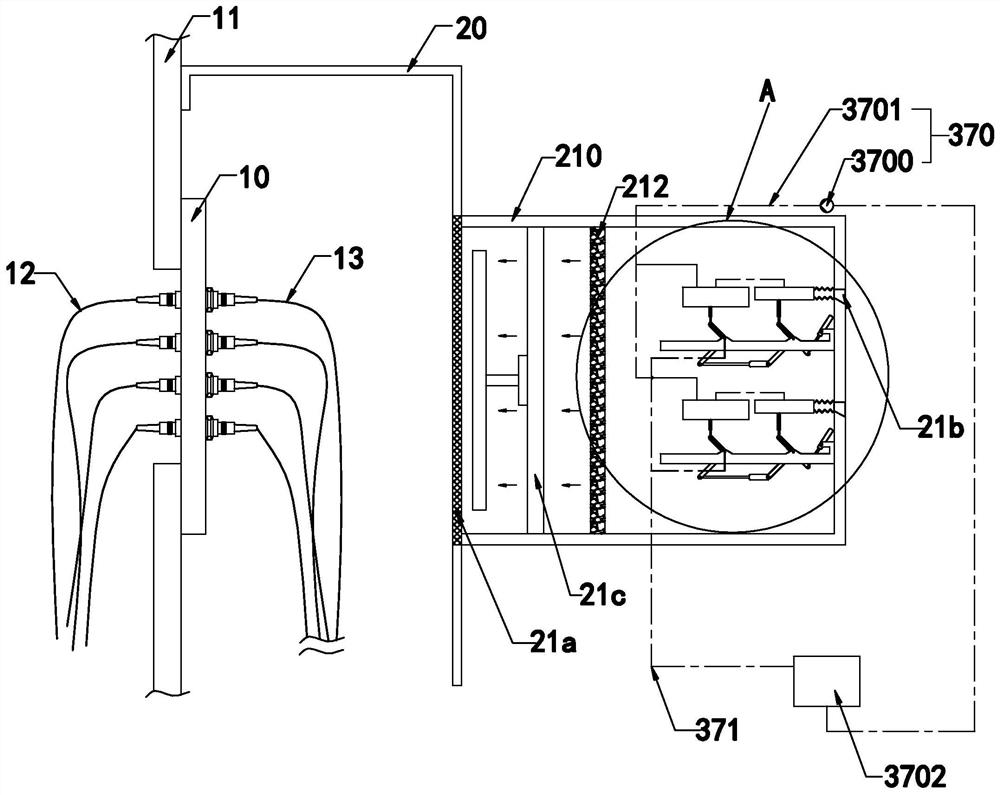

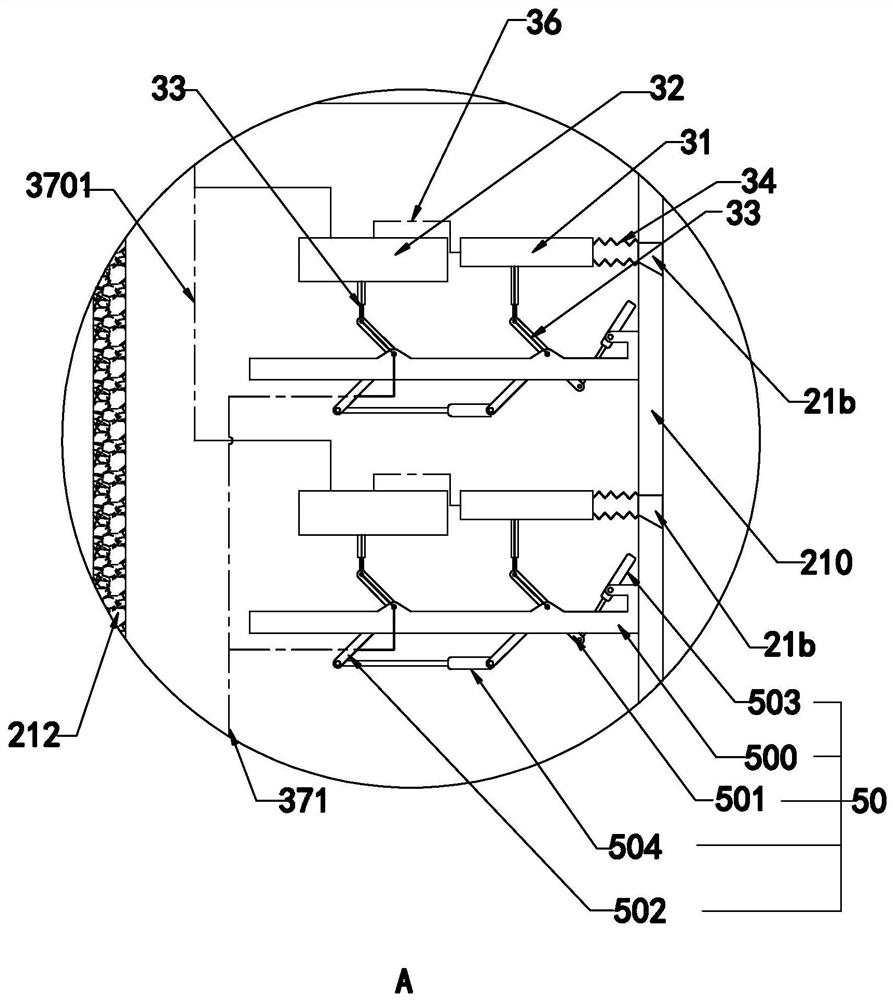

[0102] Such as Figure 2-Figure 9 Shown:

[0103] In a specific embodiment of the invention, it also includes:

[0104] The protective cover 20 is installed on the wall 11 of the transformer oil tank, and can cover and accommodate the through disk 10, the optical fiber jumper 13 and the optical fiber temperature controller 14;

[0105] The cooling device 21 is arranged on any side of the protective cover 20, and has at least an air inlet end, an air outlet end, and an air source 21c. When the air source 21c is activated, it can generate an airflow flowing from the air inlet end to the air outlet end;

[0106] Wherein, the cooling device 21 has at least a housing 210, a refrigeration unit 211 and a dehumidification unit 212. The air inlet end is arranged on the housing 210. When the air source 21c is activated, the airflow passes through the refrigeration unit 211 and the dehumidification unit 212 and into the prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com